Hankison® 2.07 kW Power Series Energy Saving Refrigerated Air Dryer

Hankison® 2.07 kW Power Series Energy Saving Refrigerated Air Dryer

SKU:REF-52f4d5

Energy-efficient refrigerated air dryer for premium air quality while saving on power costs with load matching performance.

Regular price

$4,200.00

Regular price

Sale price

$4,200.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Hankison® 2.07 kW Power Series Energy Saving Refrigerated Air Dryer delivers unparalleled energy efficiency and sustainability for industrial applications. With a rated flow of 360 scfm, voltage options to match regional requirements, and adherence to ISO standards 7183 and 8573:2010, this dryer ensures top-notch air quality with minimal energy consumption. Its load matching performance optimizes power usage based on demand, leading to substantial cost savings. The integrated features like stainless steel heat exchangers, hermetically sealed compressor, and rebatable design make it a reliable solution for institutions seeking performance, sustainability, and safety in their compressed air systems.

Product Specifications

Additional Information

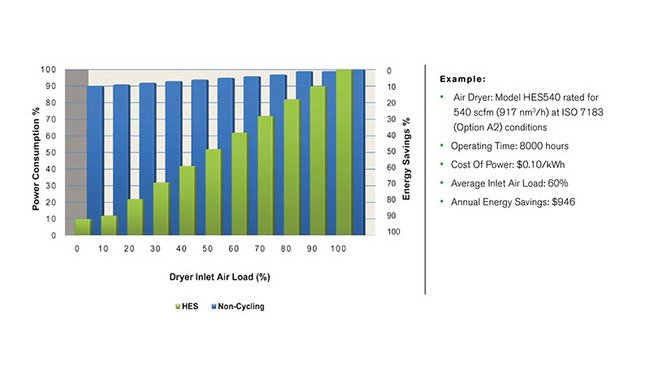

Air treatment manufacturers are challenged to design equipment that consumes less energy while operating at reduced load. Hankison® HES Series Refrigerated Compressed Air Dryers are the ideal solution!Sustainable energy saving solutions are the driving principle behind Hankison® product designs. The HES Series lowers power costs and improves productivity by matching power consumption to compressed air demand.

Delivers Iso 8573 1 Quality Class Air

The International Organization for Standardization (ISO) identified three forms of contamination as common in compressed air systems - solid particles, water and oil. ISO Standard 8573-1: 2010 categorizes each contaminant and assigns a quality class, ranging from Class 0, the highest purity level, to Class 9, the most relaxed.The HES Series effectively removes all three contaminant forms in a single air treatment system.Innovation at WorkThe standard dryer is equipped with a Grade 9 filter/separatorISO Quality Class 3: Remaining solid particulate ISO Quality Class 5: Pressure dew pointISO Quality Class 5: Remaining oil concentrationOptional Grade 5 high efficiency coalescing filters are availableISO Quality Class 1: Remaining solid particulateISO Quality Class 5: Pressure dew pointISO Quality Class 1: Remaining oil concentration

Delivers Performance Sustainability And Safety

The Drying Process-Compressed Air Circuit:Warm, saturated compressed air enters the dryer through the inlet pipe connection.Air travels through the air-to-air heat exchanger and the glycol-to-air heat exchanger. Propylene glycol surrounds the passages and cools the air to the desired pressure dew point.Moisture, solid particulates and oil aerosols are removed by the filter/separator. A no-air-loss condensate drain discharges contaminants from the system.Dry, filtered air exits the dryer for use.The Cooling Process-Glycol Circuit:Glycol exits the air-to-glycol heat exchanger and then enters the glycol storage tank.A circulation pump continuously moves the thermal medium throughout the circuit.A thermal sensor monitors the glycol temperature and turns the refrigeration compressor off whenever the glycol is cooled to its lowest temperature. The cooling medium continues to dry the air. After the medium warms up, the thermal sensor restarts the refrigeration compressor.The glycol-to-refrigerant heat exchanger chills the thermal media and travels back to the air-to-glycol heat exchanger.

Iso 8573 1 2010 Air Quality Classes Air Quality Class

0 | 1 | 2 | 3 | 4 | 5

Iso 8573 1 2010 Air Quality Classes Maximum Number Of Solid Part

≤ 100000

Iso 8573 1 2010 Air Quality Classes Total Oil Concentration Aero

4 ppm

Iso 8573 1 2010 Air Quality Classes Water Vapor Pressure Dew Poi

≤ -20 ºC | ≤ -4 ºF

Specifications Depth

32 in

Specifications Height

46 in

Specifications Inlet Connection Size

2 in

Specifications Outlet Connection Size

2 in

Specifications Power

2.07 kW

Specifications Voltage At 50 Hz Frequency

380 to 420 V

Specifications Voltage At 60 Hz Frequency

208 to 230 V | 460 V | 575 V

Specifications Width

35 in