Hankison® HES Series 2000 SCFM Refrigerated Air Dryer

Hankison® HES Series 2000 SCFM Refrigerated Air Dryer

SKU:NEW-021822

Experience energy-efficient air treatment with the Hankison® HES Series 2000 SCFM Refrigerated Air Dryer for significant cost savings and premium performance.

Regular price

$9,799.99

Regular price

Sale price

$9,799.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

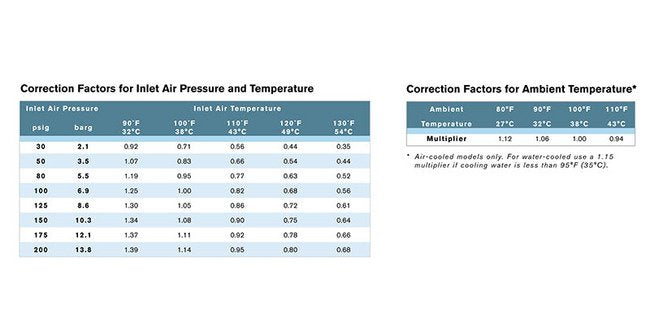

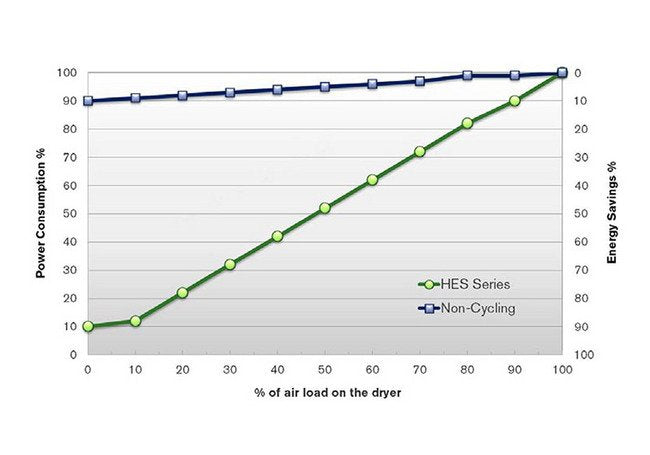

The Hankison® HES Series 2000 SCFM Rated Flow Energy Saving Refrigerated Air Dryer is a cutting-edge solution designed to efficiently treat compressed air. With a maximum working pressure of 232 psig and energy savings of up to 54% at 50% average airflow, this dryer offers exceptional performance while meeting ISO 8573-1 Air Quality Class standards. Advanced features like load matching performance, clean and dry air filtration, and rugged design make it a reliable choice for institutional and government buyers seeking energy-efficient and compliant air treatment equipment.

Product Specifications

Additional Information

Utilizing the latest technological advancements, HES Series refrigerated dryers offer a new way of thinking and an innovative approach to efficiently treat compressed air.In a typical manufacturing facility, up to 30% of electricity consumed is for generating and treating compressed air. To reduce total cost of operation and qualify for utility company incentive programs, proper air treatment equipment selection and application is required.

Customer Driven Solutions Advanced User Friendly Control

Easy to read display provides continuous operating feedbackService reminders for ease of regularly scheduled maintenanceMultiple alarms and safeties protect your investmentEnergy saving control for more efficient operationEvent log stores critical data for the operating life of the machineData logging continuously stores 60 days of operating parametersEthernet communication capability for web-based remote monitoringRS485 industrial communication protocol for remote monitoring capabilityMaster scheduler automatically controls preferred timing of dryer operationMultiple Language capability for global application

Customer Driven Solutions Energy Management Monitor Emmconnect

HES Series dryers are equipped with EMMConnect™ controls to monitor system performance, manage operation of the digital scroll compressor and track energy savings.The operator interface features a membrane touch panel, with diagnostics communicated in a user-friendly text display. A bank of light emitting diodes operate sequentially providing indication of dew point temperature in real-time.

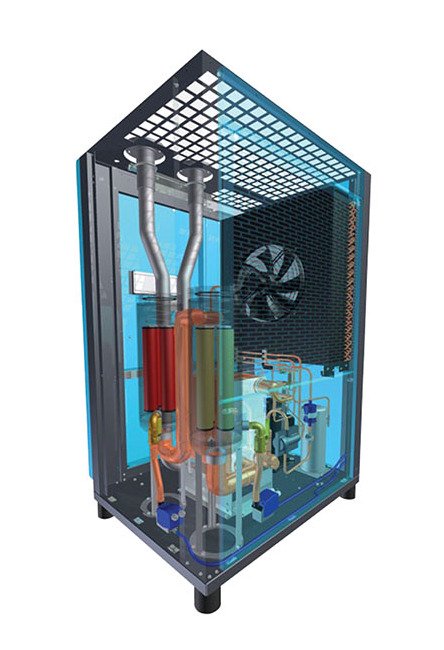

Innovation By Design Advanced Cabinet Design

The unique cabinet construction enables 360-degree access to critical components.Cam lock panel removal provides trouble-free entry for routine maintenanceBaked polyester, powder coated cabinets withstand harsh environments and maintain long-term visual appealInlet and outlet connections are located on top of the dryer, promoting ease of installation

Innovation By Design Best In Class Warranty

As an extra measure of protection, Hankison® offers an extended warranty beyond the standard 2 year coverage.Purchase an HES maintenance kit on an annual basis and receive 3 additional years of protection, parts and labor

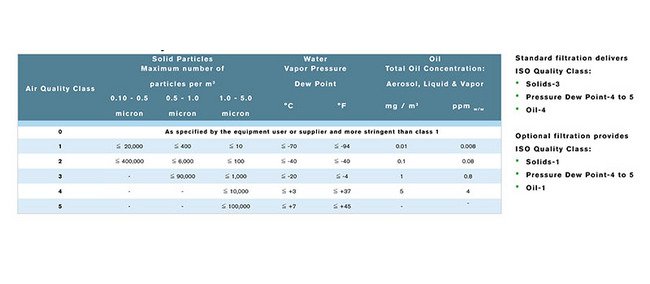

Innovation By Design Clean Dry Filtered Air

HES series dryers are self-contained air treatment stations, furnished with integrated high performance filtration.Meets ISO 8573-1: 2010 Air Quality Class standards for particle removal, pressure dew point and remaining oilAll dryers are equipped with two stage separation to remove solid particulate 3.0 micron and larger, with remaining oil content of 5.0 mg/m³Delivers ISO Quality Class 3- Solids; Class 4- OilOptional cold coalescing filters capture solid particulate 0.01 micron and larger, with remaining oil content of < 0.01 mg/m³Delivers ISO Quality Class 1- Solids; Class 1- Oil

Innovation By Design Engineered For Premium Performance

Compressed air is chilled to the specified pressure dew point in stainless steel brazed plate heat exchangers, offering corrosion resistance for the life of the dryer.Each plate is press formed with chevron patterns, creating turbulent flow, providing a self-cleaning effectSmooth, non-fouling stainless steel surfaces promote low resistance to flow, improving system efficiencyHeat exchangers are fully encapsulated in non-degrading insulation to maintain thermal efficiency

Innovation By Design Sustainable Energy Saving Solutions

To maximize full energy savings potential, refrigeration systems are designed with digital scroll compressors that load and unload based on real-time air load demand.Less energy is consumed during periods of unloading, delivering proportional energy savingsRugged design is compliant to ingestion of liquid and solids, enables non-compressible substances to pass freely though the compressorAll models utilize environmentally friendly R404A refrigerant, recognized globally as an efficient and safe HFC solution

Innovation By Design System Protection On Demand

No-air-loss, level actuated demand drains efficiently remove condensate from the system, without loss of compressed air.Condensate drain lines terminate at discharge connections conveniently located on the side of the dryerDrain assembly is equipped with an isolation valve and strainer to optimize servicePush to test button located on the operator interface enhances system reliability

Iso 8573 1 2010 Air Quality Classes Air Quality Class

0 | 1 | 2 | 3 | 4 | 5

Iso 8573 1 2010 Air Quality Classes Maximum Number Of Solid Part

≤ 100000

Iso 8573 1 2010 Air Quality Classes Optional Filtration Provides

Oil-1 | Pressure Dew Point-4 to 5 | Solids-1

Iso 8573 1 2010 Air Quality Classes Standard Filtration Delivers

Oil-4 | Pressure Dew Point-4 to 5 | Solids-3

Iso 8573 1 2010 Air Quality Classes Total Oil Concentration Aero

0.008 ppm

Specifications Depth

60 in

Specifications Height

85 in

Specifications Inlet Connection Size

6 in

Specifications Note For Optional Voltages

575/3/60 models utilize mounted transformers to step-down incoming power to 460/3/60; 230/3/60 models utilize mounted transformers to step-up to 460/3/60.

Specifications Optional Voltage

230 V | 575 V

Specifications Outlet Connection Size

6 in

Specifications Power

14.90 kW

Specifications Standard Voltage At 50 Hz Frequency

380 to 420 V

Specifications Standard Voltage At 60 Hz Frequency

460 V

Specifications Width

55 in