Hankison HHL Series Heatless Desiccant Air Dryer - 450 scfm Inlet Flow Capacity

Hankison HHL Series Heatless Desiccant Air Dryer - 450 scfm Inlet Flow Capacity

SKU:DES-62be29

Cutting-edge heatless desiccant air dryer for industrial applications, meeting ISO standards.

Regular price

$1,299.99

Regular price

Sale price

$1,299.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Hankison HHL Series Heatless Desiccant Air Dryer offers cutting-edge industrial air drying technology. With twin towers filled with premium-grade activated alumina, this dryer ensures consistent outlet pressure dew points, meeting ISO 8573.1 Quality Classes standards. Designed for industries like pharmaceutical manufacturing and microelectronics, it features AccuShift™ Switching Valves for precise control and offers energy-saving Purge Economizer settings for peak efficiency.

Product Specifications

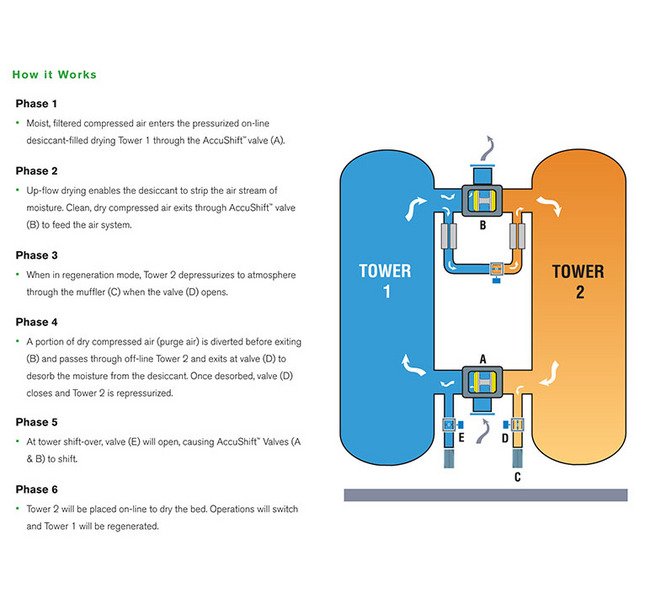

Application Specific Designs How It Works

Phase 1 - Moist, filtered compressed air enters the pressurized on-line desiccant-filled drying Tower 1 through the AccuShift™ valve (A).Phase 2 - Up-flow drying enables the desiccant to strip the air stream of moisture. Clean, dry compressed air exits through AccuShift™ valve (B) to feed the air system.Phase 3 - When in regeneration mode, Tower 2 depressurizes to atmosphere through the muffler (C) when the valve (D) opens.Phase 4 - A portion of dry compressed air (purge air) is diverted before exiting (B) and passes through off-line Tower 2 and exits at valve (D) to desorb the moisture from the desiccant. Once desorbed, valve (D) closes and Tower 2 is repressurized.Phase 5 - At tower shift-over, valve (E) will open, causing AccuShift™ Valves (A & B) to shift.Phase 6 - Tower 2 will be placed on-line to dry the bed. Operations will switch and Tower 1 will be regenerated.

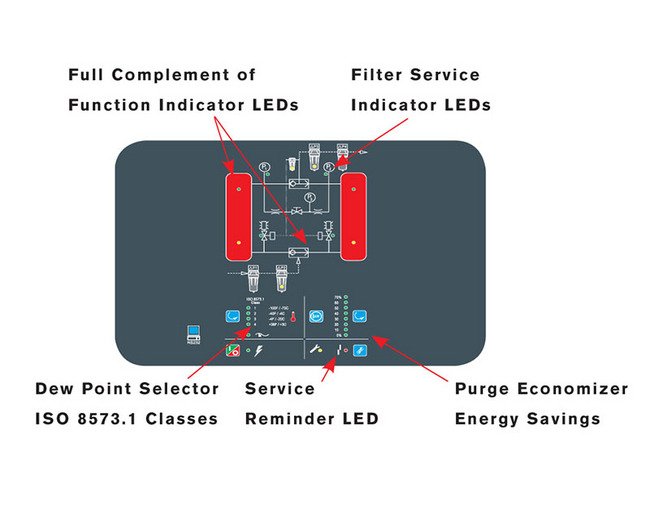

Controller Features

Choice of four fixed cycle operating modes corresponding to ISO 8573.1 Air Quality ClassesChoice of eight Purge Economizer Energy Savings settingsSwitches for On/Off, Alarm and Service reminder resetOperational LED lights for power-on, tower status, valve status, and tower pressureAlarm LED for valve switching failureRS-232 communications port is standardService reminder LED lights for filters and drains, valves and desiccant

Dedicated To Excellence

Since 1948, compressed air users around the world have relied on Hankison® to provide innovative compressed air treatment solutions for critical applications.Hankison® maintains a long standing reputation for manufacturing products that deliver superior performance, time proven reliability and optimal energy savings.Hankison® today is the preferred choice for providing clean, dry compressed air for the most challenging industries.

Four Dew Point Options Per Iso 8573 1 Air Quality Standards

Specifying a pressure dew point is not simple work for an engineer. Hankison® Heatless dryer designs allow you to optimize performance and dew points in the field to adapt to your environment and meet the following ISO 8573-1 Classes of air quality.

Inlet Flow

Inlet flow capacities are established in accordance with CAGI (Compressed Air and Gas Institute) standard ADF-200: Inlet air pressure 100 psig (6.7 barg), inlet temperature saturated at 100 ºF (38 ºC). To determine inlet flow at pressures other than 100 psig (6.7 barg), multiply inlet flow at 100 psig (6.7 barg) from Product Specifications by the corresponding multiplier.

Iso 85731 Quality Classes Cycle Time For Iso Quality Class 1

4 min. Fixed

Iso 85731 Quality Classes Cycle Time For Iso Quality Class 2

10 min. Fixed

Iso 85731 Quality Classes Cycle Time For Iso Quality Class 3

16 min. Fixed

Iso 85731 Quality Classes Cycle Time For Iso Quality Class 4

24 min. Fixed

Iso 85731 Quality Classes Dew Point

-100 ºF | 38 ºF | -4 ºF | -40 ºF | -20 ºC | 3 ºC | -40 ºC | -73 ºC

Iso 85731 Quality Classes Remaining Moisture At Dew Point 100 F

0.12 ppmw | 0.15 mg/m³

Iso 85731 Quality Classes Remaining Moisture At Dew Point 38 F 3

610 ppmw | 730 mg/m³

Iso 85731 Quality Classes Remaining Moisture At Dew Point 40 F 4

10 ppmw | 12 mg/m³

Iso 85731 Quality Classes Remaining Moisture At Dew Point 4 F 20

81 ppmw | 97 mg/m³

Note

Dimensions and weights are for reference only. Request certified drawings for construction purposes.

Precision Performance Engineered To Order Options

High dew point alarm which includes light and voltage free contacts for remote alarmDew point monitor, includes digital display, voltage-free contacts and recorder outputLow ambient packages, epoxy paint, severe environment protectionOil-free packages with integrated activated carbon towers

Precision Performance Industry Leading Design

Consistent outlet pressure dew pointsPremium grade desiccant beads enhance surface area and have high crush strengthLarge desiccant beds ensure 4.8 seconds of contact timeLarge flow diffusers ensure even flow distribution through the bed and eliminate channelingTowers are designed to prevent fluidization of the desiccantUp-flow drying allows water and heavy contaminants to drop out of the air streamSimple discharge of contaminantsCleanable stainless steel flow diffusers/support screensSeparate fill and drain ports for ease of desiccant replacement

Precision Performance Integrated Filtration

Optional pre-filter and after-filter packages, featuring Hankison® NGF Series filters, can be pre-installed at theGrade SF and Grade HF pre-filters are recommended for -40 ºF to 38 ºF (-40 ºC to 3 ºC) dew pointsGrade PF and Grade UF pre-filters are recommended for -100 ºF (-73 ºC) dew pointsGrade PF and Grade CF are the recommended after-filters

Precision Performance Precision Accushift Switching Valves

Automatically shift to the low pressure side of the circuit to control process flowPosition memory ensures drying continues even without power5 year AccuShift™ valve replacement warrantyThree-way pilot operated solenoid valves manage the pilot air flow to direct the purge/repressurization valvesPurge pressure adjustment valve1 Dryer must be protected by properly sized Hankison® prefilter. Parts and labor covered through first year of warranty, parts only in second through fifth years.

Precision Performance Safety Built To Code

Pressure vessels are CRN and ASME CertifiedHeavy-duty mufflers for quiet operationNEMA 4 electrical construction is standardPressure relief valves are standard

Selectable Purge Economizer Savings

HHL Series provides user selectable energy savings with tailored drying cycles designed to match your peak air demands.Reducing the amount of time the dryer spends purging in the regeneration cycle can save energy. Eight settings (0% to 70% in 10% increments) are furnished for users to lower the purge to match reduced air loads on the dryer. Each energy saving setting has an LED light which will illuminate when it is selected. Simply flip the switch to select the desired energy saving setting.In addition, this state-of-the-art controller offers four pressure dew point settings to further tune your savings and adapt the system to your environment.

Specifications Available Voltage

100 to 240 V

Specifications Depth

38 in

Specifications Direct Current Dc Voltage

12 to 24 V

Specifications Frequency

50 to 60 Hz

Specifications Height

71 in

Specifications Industry

Industries such as pharmaceutical manufacturing, laboratories, hospitals, microelectronics, food packaging, paper, glass and powder painting with low dew point requirements, utilize heatless desiccant air dryers.

Specifications Industry Standardscertifications

ASME Approved | CRN | NEMA 4

Specifications Inlet Connection Size

2 in

Specifications Inlet Connection Type

NPT

Specifications Inlet Flow Capacity At 100 Psig 67 Bar Pressure

450 scfm | 765 nm³/h

Specifications Maximum Inlet Air Or Ambient Air Temperature

120 ºF | 49 ºC

Specifications Maximum Optional Working Pressure

250 psig | 17.6 bar

Specifications Maximum Standard Working Pressure

150 psig | 10.5 bar

Specifications Minimum Operating Pressure

60 psig | 120 psig | 150 psig | 250 psig | 4.2 bar | 8.4 bar | 10.5 bar | 17.6 bar

Specifications Note For Connections

BSP and DIN flanges available.

Specifications Outlet Connection Size

2 in

Specifications Outlet Connection Type

NPT

Specifications Width

55 in