Heidon Tribogear HHS2000 Friction & Wear Measurement System

Heidon Tribogear HHS2000 Friction & Wear Measurement System

SKU:TRI-7f6a7f

Advanced friction and wear measurement system for precise material evaluation in various industries.

Regular price

$17,999.00

Regular price

Sale price

$17,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

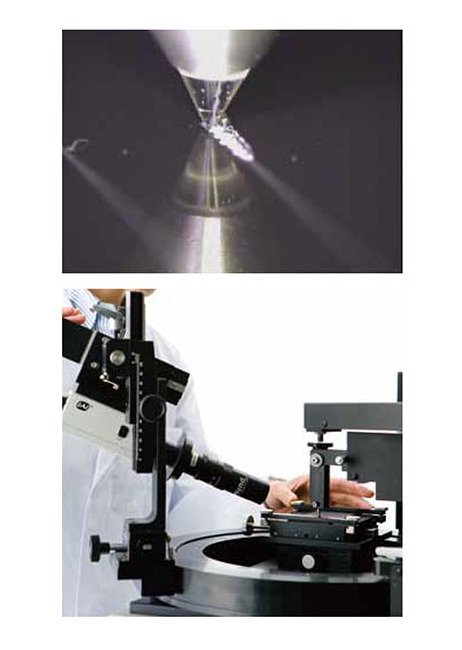

The Heidon Tribogear HHS2000 is the pinnacle of wear testing technology. This advanced system allows for precise friction and wear measurements with unparalleled accuracy. Featuring multiple testing capabilities in a single machine, automatic test programming, and high-resolution data collection, it streamlines the testing process for both efficiency and exceptional results. With the ability to evaluate various materials' surface properties, including coatings, films, and thin films, it is widely utilized in industries like coating, printing, electronics, automotive, and research institutions. The inclusion of a CCD camera system for real-time wear progress monitoring further enhances its functionality, making it a must-have for precise and reliable wear testing requirements.

Product Specifications

Additional Information

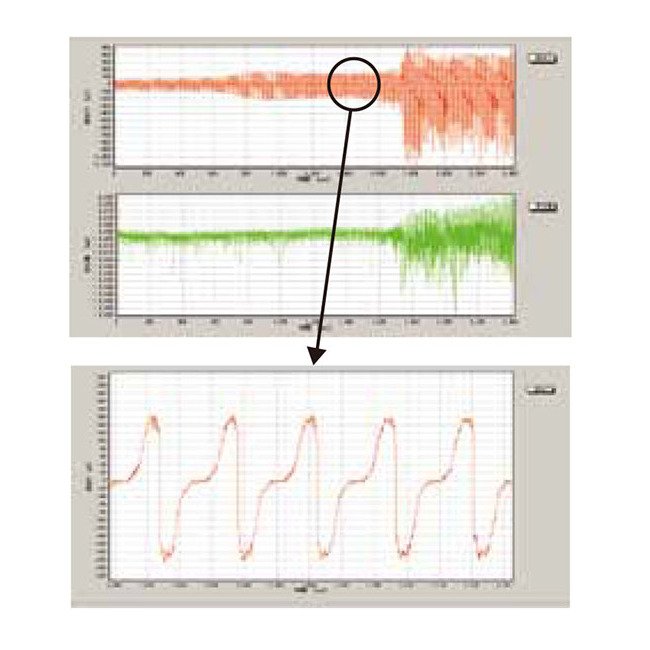

Adding Various Functions While Maintaining the Previous Reliability of the Measuring SystemThe loading method uses the traditional tribogear balance arm mechanism to maintain the high reliability.Switching between the fixed loading and continuous loading testing modes can be easily carried out using the touch panel.For the loading, too, the previous mechanism requiring weights to be placed manually has evolved into an automatic system based on numerical input.Furthermore, a rich variety of functions have been added, including a moveable table with standard Y-direction stage and angle adjusting functions.Examples of the Wear Mode MapFriction(Red) and displacement(Green) curves on the variable normal load measurement.This is the top device of the Heidon Tribogear series and was developed together with Tohoku University.It enables evaluation of surface properties of materials, by single or continuous load tests. Variable Load Tests where the load increases on the way forth and decreases on the way back are a special feature of this machine. With the included software you can create 3-dimensional wear condition graphs showing the relation between number of wear movements, vertical load, friction and wear. Thus, you can determine the critical loading based on wear transitions.

Advantages

Multiple tests with one and the same machine possibleMultiple test pieces not necessaryHigh resolution data collectionAutomatic test programmingAutomatic data analysisShort testing timeOptional CCD camera system for watching wear progressVertical loading can be selected freely between 1 g and 10,000 g

Applications

Evaluation of friction, density, durability, scratch resistance of coatings (including DLC), films, thin films, magnetic and chip cards.Used widely in the coating, printing, electronic and automotive industries, as well as in research ins

Dynamic Strain Amplifier Filter

1, 10, 100 Hz, Pass (Low Pass Filter)

Dynamic Strain Amplifier Output Non Linear

0 to ±5 V (±0.05% Full Scale or Less)

Dynamic Strain Amplifier Response Frequency Characteristics

2 kHz/-3 dB

Dynamic Strain Amplifier Sensitivity Switching Full Scale

0 % | 10 % | 100 % | 25 % | 50 %

Dynamic Strain Amplifier Signal To Noise Sn Ratio At Maximum Sen

60 dB

Dynamic Strain Amplifier Zero Point Adjustment

Digital Servo Auto Zero Reset Method

Main Unit Dimensions Main Unit Depth

490 mm

Main Unit Dimensions Main Unit Height

665 mm

Main Unit Dimensions Main Unit Width

730 mm

Technical Specs Alternating Current Ac Voltage

100 V

Technical Specs Brands

Heidon

Technical Specs Drive Method

Rack and Pinion

Technical Specs Drive Motor

Alternating Current (AC) Servo Motor

Technical Specs Fixed Loading Travel Distance

1 to 50 mm

Technical Specs Frequency

50 Hz | 60 Hz

Technical Specs Loading Converter Capacity High Loading Unit

19.61 N

Technical Specs Loading Converter Capacity Low Loading Unit

0.98 N

Technical Specs Loading Variationcontinuous Loading Travel Dista

10 to 50 mm

Technical Specs Pre Start Mode

Fixed Loading/Continuous Loading Switching

Technical Specs Safety Equipment

Overloading Safety Equipment (Overload)High Frequency Noise Prevention Circuit

Technical Specs Table Size

120 x 100 mm

Technical Specs Table Travel Mode

Single/Repeat Switching

Technical Specs Travel Speed

0.1 to 50 mm/s

Technical Specs Usage Environment

0 to 50 ºC, RH 85 % or Less, Non-Condensing

Technical Specs Vertical Loading High Loading Unit

10 to 1000 g

Technical Specs Vertical Loading Low Loading Unit

1 to 50 g

Tribogear Option

ASTM Flat IndenterAdapted specifications: ASTM D1894Contact surface: 2.5 x 2.5 inchCan apply surface pressure to the paired test pieces after the sheet-type test piece is wound and fixed and the plate-type test piece is bonded.30 mm Flat IndenterContact surface: 30 x 30 mmCan apply surface pressure to the paired test pieces after the sheet-type test piece is wound and fixed and the plate-type test piece is bonded.Ball IndenterApplies point pressure to the plate-and sheet type test pieces using a secured ball which slides the test pieces. This device is suitable to measure the difference between the test pieces based on the ball.Sand-Contained Rubber Eraser IndenterHolds a cylindrical sand-contained rubber eraser in order to measure changes in friction due to the abrasion of the test piece.Steel-Wool HolderHolds steel wool, gauze or rubber in order to measure changes in friction due to the abrasion of the test piece surface.Scratch NeedleAdapted specifications: JIS K6718 Evaluates the scratch hardness of various materials and the adhesion of vacuum evaporated or paint film.45º Pencil Holder Adapted specifications: JIS K5600 (scratch test) Measures the scratch hardness of coated surfaces and evaluates how smoothly pens or pencils write.Heating MechanismLiquid Receiving VatCooling Mechanism