High-Efficiency Universal Solvent Circulation Heaters

High-Efficiency Universal Solvent Circulation Heaters

SKU:UNI-fba9d8

Efficiently heat low flash point solvents with precision and safety in semiconductor processes.

Regular price

$799.99

Regular price

Sale price

$799.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The High-Efficiency Universal Solvent Circulation Heaters are designed for safe and precise heating of low flash point solvents in semiconductor wet process systems. Featuring cast aluminum construction with seamless 316L stainless steel tubing, these heaters ensure contamination-resistant surfaces and efficient heat transfer. With an explosion-proof NEMA 7 enclosure, UL®/CSA recognized heater elements, and compliance with industry standards, these circulation heaters deliver reliable performance in demanding environments. The self-draining design, high-pressure operation capability, and over-temperature protection enhance safety and productivity in various applications.

Product Specifications

Additional Information 0

The universal solvent circulation heater provides a safe and efficient means of heating low flash point solvents. Both the heating elements and the solvent tube are cast into the aluminum. The heating elements provide heat to the aluminum mass and the mass transfers this heat to the tube carrying the solvent. The casting can also be surrounded by insulation to minimize heat loss and keep equipment cabinet temperatures low. A secondary chilled water tube is also cast-in. This tube quickly cools the casting for routine maintenance or lowers the solvent below the flash point.Safety features of the universal solvent circulation heater include a NEMA 7 rated (explosion proof) enclosure box covering the electrical connections and a snap-action over temperature protection switch to provide safe shut down. The casting body is PTFE coated to protect the aluminum in case of accidental contact with solvents.The universal solvent circulation heater is appropriate for numerous applications and may be customized to meet specific customer needs.High limit, auto resetting snap-action switch.

Applications 0

Semiconductor Wet Process Systems.Wafer Cleaning Equipment (Wet Bench Systems).Post Etch Wet Strip and Photoresist Removal Applications.Heating of Low Flash Point Solvents such as EKC, ACT and NMP.

Features And Benefits 0

Fluid path constructed independent from heater sheathAllows solvent to never be in contact with heater element.Eliminates hot spots caused by poor flow or start up conditions.Cast aluminum constructionAllows accurate process temperature control.Provides rugged design and durability.Higher reliability due to fewer components and non-welded construction.Ensures longer heater life.Material compatibility with most semiconductor solvents316L Stainless Steel passivated and electropolished solvent tube.Ensures contamination resistant surface for heated solvent.Assures higher reliability and cleanliness due to seamless tubing.Operates to 1500 psi or greater with appropriate fittingsEnables economic high pressure operation.Self-draining construction when mounted verticallyEliminates trapped material that may add contamination to the process.Saves on operating time.Agency ratings to comply with safety standardsUL®/CSA recognized heater elements.NEMA 7 Class 1, Div. 1 and 2, Groups B, C and D electrical enclosure.Reduces risk of accidental combustion of solvent vapors.

Fitting Connections 0

Flaretek® or Swagelok VCR fittings on solvent tube.National Pipe Thread (NPT) or Swagelok VCR fittings on cooling tube.

Note 0

Note for Casting Dimensions - Dimensions above do not include tube fittings and mounting bosses.

Sensorsswitches 0

2 cast-in Type J thermocouples sense solvent tube inlet and outlet temperatures.1 replaceable Type J thermocouple senses casting core temperature.Mechanical snap action switches for over temperature protection.

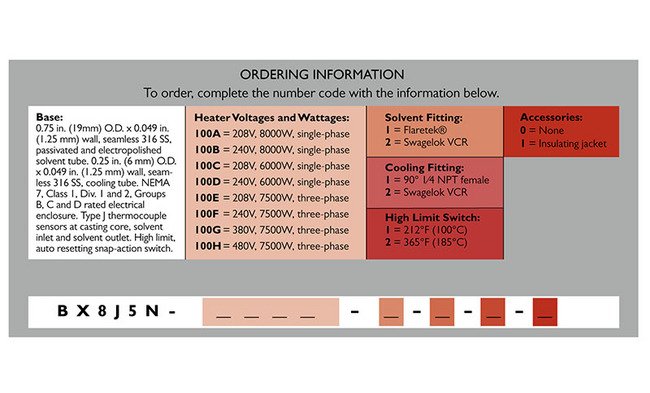

Specifications Accessories

Insulating jacket | None

Specifications Ambient Operating Temperature

392 ºF | 200 ºC

Specifications Casting Diameter

5.75 in | 146 mm

Specifications Casting Height

8.5 in | 216 mm

Specifications Cooling Fitting

Swagelok VCR | 90º 1/4 NPT female

Specifications Enclosure Diameter

4.75 in | 121 mm

Specifications Enclosure Height

5 in | 127 mm

Specifications Enclosure Rate

Enclosure rated for Class 1, Div. 1 and 2, Groups B, C and D

Specifications Heater Wattage For Single Phase

6000 to 8000 W

Specifications Heater Wattage For Three Phase

7500 W

Specifications High Limit Switch

212 ºF | 365 ºF | 100 ºC | 185 ºC

Specifications Industry Standards

CSA | UL®

Specifications Maximum Temperature

400 ºF | 204 ºC

Specifications Operating Pressure

1500 psi

Specifications Optional Features

Insulating jacket

Specifications Outer Diameter Cooling Water Tube

0.25 in | 6 mm

Specifications Phase

Single | Three

Specifications Ptfe Coated Castinganodized Electrical Enclosure

Protects unit from accidental contact with corrosive process solvents

Specifications Solvent Fitting

Flaretek® | Swagelok VCR

Specifications Terminal Housing

NEMA 7

Specifications Tubing Material

316L Stainless Steel Seamless Tubes

Specifications Tubing Wall Thickness

0.049 in | 1.25 mm