High-Speed Continuous Motion Shrink Wrapper with Integrated Tunnel

High-Speed Continuous Motion Shrink Wrapper with Integrated Tunnel

SKU:SHR-75eca4

Efficiently wrap printed materials with precision and speed using our High-Speed Continuous Motion Shrink Wrapper with Integrated Tunnel by ARPAC.

Regular price

$28,999.99

Regular price

Sale price

$28,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

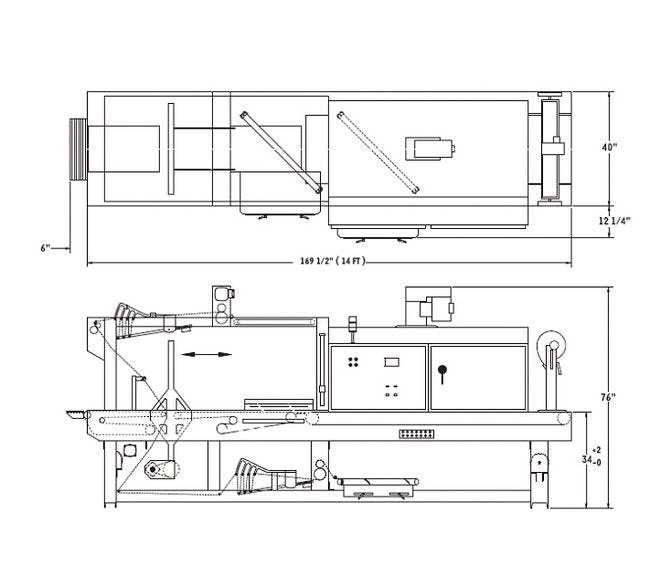

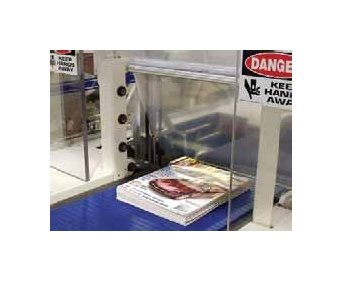

The High-Speed Continuous Motion Shrink Wrapper with Integrated Tunnel by ARPAC is a cutting-edge solution designed for the high-volume printing and publishing industry. With a capacity of wrapping up to 75 bundles per minute, this compact machine efficiently wraps magazines, catalogs, books, and other printed materials on-demand without disrupting production. Its servo-driven sealing system ensures precise electronic control for immediate and accurate sealing action, delivering strong and consistent seals. Crafted with heavy-duty stainless steel and equipped with advanced features like servo-controlled continuous motion seal head and quick-change plasma-coated seal bars, this shrink wrapper guarantees durability, reliability, and exceptional performance round the clock.

Product Specifications

Additional Information Additional Information

Servo drives enhance this industry standard's performance by eliminating pneumatic components. These drives significantly reduce wear, maintenance costs, and extend the life of the seal carriage. Servo drives ensure smooth operation while providing high quality sealing for the life of the machine. Designed to interact with todayâs 18,000 to 20,000 books-per-hour binding lines, the 75GI is perfect for presorted postal route sequencing applications, and the printing and publishing industryâs fastest counter stackers. Up to 75 bundles per minute Smooth, quiet operation Wraps fixed or random sized stacks on demand Reduced maintenance

Electrical Power Requirements Alternating Current Ac Voltage

460 V

Electrical Power Requirements Current

40 A

Electrical Power Requirements Frequency

60 Hz

Electrical Power Requirements Number Of Phase

3

Factory Acceptance Test Fat Factory Acceptance Test Fat

75GI-24X Option, One day Factory Acceptance Test for one product size is included. If more Factory Acceptance Testing is required see Machine Options, "Testing of additional products (each)", for price of each additional product.

Features Features

Heavy-duty rugged construction designed for high durability and around-the-clock operationCompact, single frame design(wrapper with integrated tunnel)Laser cut and CNC machined components for maximum precisionSpeeds up to 75 bundles per minuteWraps random sized stacks on demandServo controlled continuous motion seal head provides smooth and quick transition of product through the wrappe rat high speedsServo drives provide excellent repeatability throughout the life of the machineQuick change plasma-coated seal bars for long life and easy maintenanceTiming belt stabilized seal frame reduces maintenance and dirt accumulationIndependent variable speed driveson the wrapper and tunnelZero tension film feed prevents paper sheets or slippery magazines from shinglingSide mounted film cradles for easy film loadingShrink tunnel with product cooling sectionat the tunnel exit speeds film curingDurable Intralox conveyor belts eliminate tracking problemsLow film alert warns that a film change over will soon be necessaryAllen-Bradley® programmable logic controller with ARPAC standard operator interfaceDigital controls for fast and accurate setupNEMA 12 electrical cabinet and controlsCentral point lubrication allows for routine maintenance without stopping production

Options Options

ARPAC can design and build a system to suit your specific applicationCasters for machine portabilityCollating systems for grouping stacks of products together before they proceed through the seal frame and into the shrink tunnelOn certain high-gloss or stitched products, static charging may be necessary to hold the bundle together while shrink wrapping. Please consult ARPAC when this may be an issueSide smoothing rollers to smooth out odd shaped bull's eyesSplit belt infeedTesting of additional products (each)Special feet for + 3 elevation adjustment, Min elevation is 34"Auxiliary E-StopUL/CSA approved main electrical cabinetNinety degree curved belt infeed

Specifications Applications

Books | Catalogs | Magazines | Mailers | Newspapers | Paper Products | Periodicals | Tabloids

Specifications Cabinet Standards

NEMA 4X

Specifications Compressed Air Requirements

80 psi | 12 scfm

Specifications Delivery Times

8 to 10 w

Specifications Film Gauge

1.5 to 2.5 mil

Specifications Film Roll Diameter

0 to 14 in

Specifications Film Roll Width

6 to 19 in

Specifications Film Type

Low Density Polyethylene (L.D.P.E.)

Specifications Frame Material

Stainless Steel

Specifications Height

3/16 to 10 in

Specifications Length Flow Direction

7 to 22 in

Specifications Other Film Specifications

Clear or Randomly Printed | Core of Film Roll - Up to 3 in.

Specifications Output Speed

Up to 75 packages per minute

Specifications Width Across Machine

5 to 12 in