High Voltage Double-Ended Shielded Cable Assembly - Series 311

High Voltage Double-Ended Shielded Cable Assembly - Series 311

SKU:HIG-0093a9

High Voltage Double-Ended Shielded Cable Assembly - Series 311, designed for reduced pressure, with 10 Amp current rating & 70,000 ft. altitude rating.

Regular price

$89.99

Regular price

Sale price

$89.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The High Voltage Double-Ended Shielded Cable Assembly in Series 311 is designed for exceptional performance in reduced pressure environments. Featuring a hooded female socket, shell-to-shell grounding spring finger shield, and bayonet coupling with machined rings for precise polarization, this assembly ensures reliable connections. With a current rating of 10 Amp and an altitude/reduced pressure rating of 70,000 ft., this cable assembly meets stringent operational requirements. The brass coupling nut with nickel finish and gold-plated body properties enhance durability and conductivity, making it ideal for high voltage applications.

Product Specifications

Body Properties Coupling Nut Finish

Gold Plated

Body Properties Coupling Nut Material

Brass

Cable Preparation 0

Reynolds Industries Inc. - High Voltage Connectors, High Voltage Cable Assemblies, High Voltage Wire, High Voltage Cable, High Voltage Capacitors _uacct = "UA-425769-1"; urchinTracker(); CLICK HERE FOR A PHOTOGRAPHIC "HOW TO" Series 311 (P/N 167-7624) Step 1 Cut cable to length, clean and square. Slip boot and crimp sleeve over cable. Strip outer jacket to dimension shown. Trim exposed braid to dimension. Trim inner insulation to dimension. No nicked or severed strands allowed. Pot tin dip inner conductor using SN60 solder in accordance with J-STD-006. Remove all flux. Step 2 Solder contact in place through hole using SN60 solder in accordance with J-STD-006. No solder buildup allowed on contact outer diameter. Completed solder joint must have a continuous fillet of solder between the inner conductor and the contact. The solder in the feed hole must be free of pinholes and flush or below flush. Rear of contact shoulder shall be as flush as possible with insulation of cable core, but not to exceed .030". Flair braid by moving cable core in a circular motion. Step 3 Solder contact in place through hole using SN60 solder in accordance with J-STD-006. Completed solder joint must have a continuous fillet of solder between the conductor and the contact. The solder in the feed hole must be free of pinholes and flush or below flush. Rear of contact shoulder shall be as flush as possible with insulation of cable core, but not to exceed .030". Download this page as a PDF for best print quality.

Specifications Altitudereduced Pressure Rating

70,000 ft.

Specifications Assembly Type

Double-Ended Plug Cable Assembly

Specifications Bayonet Coupling Nut Finish

Nickel

Specifications Bayonet Coupling Nut Material

Brass

Specifications Coupling Style

Bayonet

Specifications Current Rating

10 Amp

Specifications Export Classification

TBD

Specifications Mating Compatibility

Mates all series 311 receptacles with corresponding Polarization Condition.

Specifications Operating Temperature

-40 to 85 ºC

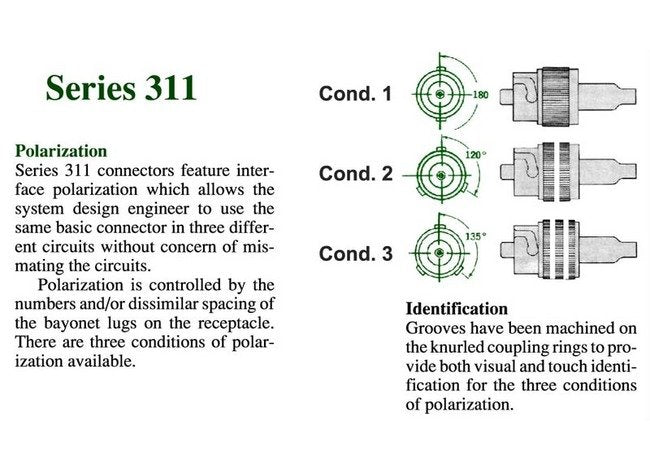

Specifications Polarization

Cond. 1

Specifications Rohs Compliant

TBD

Specifications Sealed Receptacle

N/A

Specifications Series

311

Specifications Spring Finger Grounding

Yes

Specifications Standardnon Standard

Standard Part

Specifications Test Voltage

21 kVDC at 70000 ft. (simulated) and ambient temperature

Specifications Voltage Rating

15 kVDC