HTA Series High Temp Afterfilter - 100 scfm

HTA Series High Temp Afterfilter - 100 scfm

SKU:AIR-9a591b

Optimized HTA Series Afterfilter for high-temp applications, 100 scfm flow, 3-stage filtration, max 450 ºF

Regular price

$649.99

Regular price

Sale price

$649.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The HTA Series High Temperature Afterfilter by Hankison® is engineered for high dust loading capacity and extended cartridge life, making it an ideal solution for high temperature applications. With a maximum flow of 100 scfm, this afterfilter operates at temperatures up to 450 ºF and removes solid particles as small as one micron. Featuring three-stage filtration for efficient particle capture, this afterfilter ensures clean and quality compressed air downstream of heated desiccant air dryers.

Product Specifications

Additional Information

High dust loading capacity - long cartridge life.Good for temperatures to 450 ºF (232 ºC).Removes all solid particles one micron and larger.

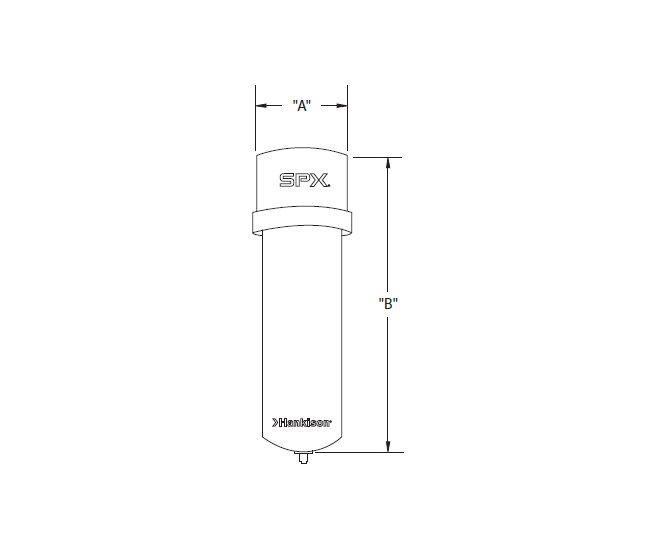

Specifications Height B

14.31 in

Specifications Housing Type

Bowl | Head

Specifications Inlet Connection Size

1 in

Specifications Inlet Connection Type

NPT

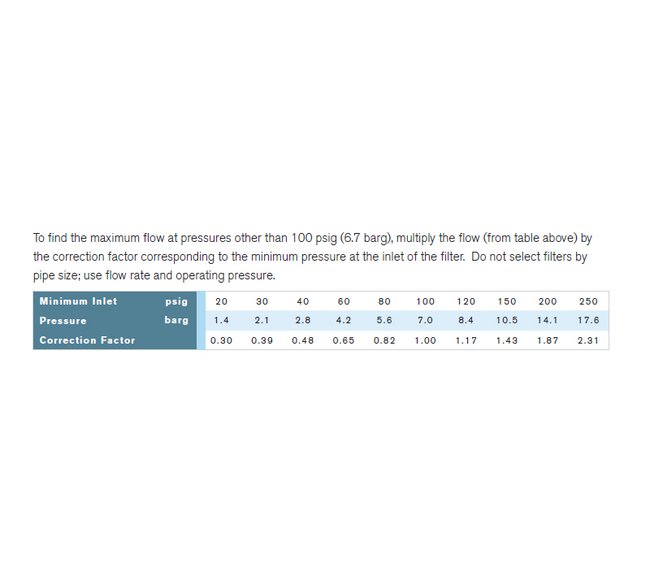

Specifications Maximum Flow At 100 Psig 67 Bar

100 scfm | 170 nm³/h

Specifications Maximum Temperature

450 ºF | 232 ºC

Specifications Maximum Working Pressure At 450 F 232 C

250 psig | 17.6 bar

Specifications Outlet Connection Size

1 in

Specifications Outlet Connection Type

NPT

Specifications Quantity Required

1

Specifications Replacement Cartridge Number

0740-1

Specifications Series

HTA

Specifications Weight

13 lb

Specifications Width A

4.25 in

Three Stage Filtration Operation Stage 1 Gravitational Setting

Compressed air leaves a desiccant dryer containing dust concentrations typically in the range of up to 0.05 ppm by weight in heatless type dryers and up to 5 ppm by weight in heated type dryers. Particle size ranges from 200 microns to about 1 micron. This desiccant laden compressed air enters the filter housing where a reduction in air velocity and a sharp change of direction cause particles in the range of 200 to 20 microns to drop to the bottom of the housing.

Three Stage Filtration Operation Stage 2 Surface Filtration

The air stream then enters the outside of the filter cartridge and flows through a layer of glass fabric cloth. Small diameter fibers, which form a web in the openings between thread strands, cause a dust layer to form as dust bridges the pores. Dust continues to collect on the outside of the cloth as separate loose particles. The voids between these particles form pores and flow-passages and become an efficient filter in itself.As the dust bed continues to thicken it reaches a point where outer layers of dust shed off the cartridge into the bottom of the housing.

Three Stage Filtration Operation Stage 3 In Depth Filtration

Air next travels through a multi-layer graded in-depth filter media where all remaining fines one micron and larger are captured.A final wrap of glass fabric cloth prevents fiber migration.