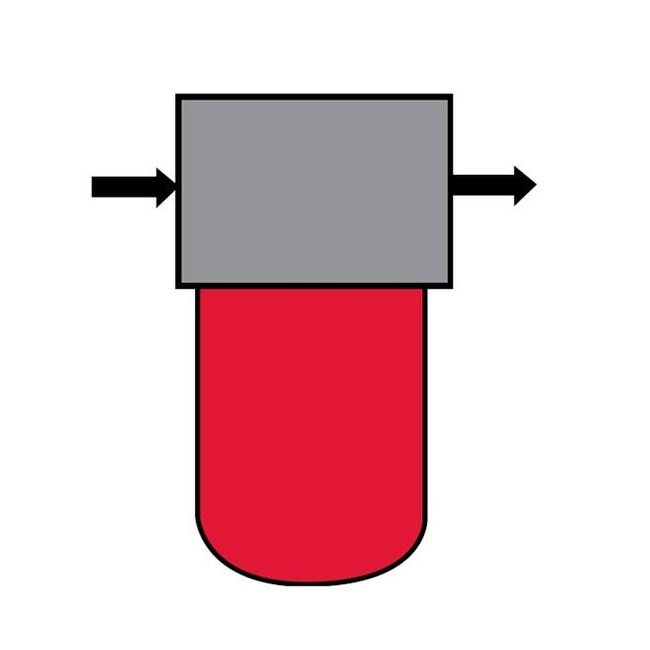

Hydac DF Series High Pressure In-Line Industrial Filter (6090 PSI)

Hydac DF Series High Pressure In-Line Industrial Filter (6090 PSI)

SKU:HYD-308b9b

High Pressure In-Line Industrial Filter for 6090 PSI, 63 gpm flow capacity, durable design, and reliable performance

Regular price

$799.99

Regular price

Sale price

$799.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Hydac DF Series High Pressure In-Line Industrial Filter is designed to handle up to 6090 psi and flow rates of up to 200 gpm with a flow capacity of 63 gpm. This filter features a non-welded housing design, various port configurations, and robust construction materials for maximum durability. With seals made of Fluorocarbon Elastomer (FKM) and compatibility with various fluids, this filter ensures reliable performance in demanding industrial applications. It also includes a poppet-type bypass valve for enhanced system reliability and ease of maintenance.

Product Specifications

Application 0

AgriculturalAutomotiveConstructionGearboxesIndustrialPulp & PaperOffshoreRailwaysCommercial MunicipalShipbuildingPower GenerationSteel / Heavy Industry

Dimensions Diameter D1

4.69 in | 119 mm

Dimensions Dimension B1

4.92 in | 125 mm

Dimensions Dimension B2

3.74 in | 95 mm

Dimensions Dimension B3

3.35 in | 85 mm

Dimensions Dimension B4

1.38 in | 35 mm

Dimensions Dimension D2

3.74 in | 95 mm

Dimensions Dimension D3

1-1/4 in.

Dimensions Dimension D4

3/8-24UNF- 2B

Dimensions Dimension H1

11.91 in | 302.5 mm

Dimensions Dimension H2

1.85 in | 47 mm

Dimensions Dimension H3

4.13 in | 105 mm

Dimensions Dimension H4

4.13 in | 105 mm

Dimensions Dimension T1

0.55 in | 14 mm

Features 0

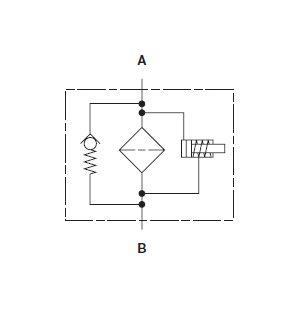

Non-welded housing design reduces stress concentrations and prevents fatigue failure.Choice of NPT, BSPP, SAE straight thread O-ring boss, and SAE 4-bolt flange porting (sizes 60 - 1320) to allow easy installation with maximum flexibility.O-ring seals are used to provide positive, reliable sealing.Choice of O-ring materials (nitrile rubber, fluorocarbon elastomer, and ethylene propylene rubber) provides compatibility with petroleum oils, synthetic fluids, water-glycols, oil/water emulsions, and high water based fluids. Screw-in bowl or lid (on 2-pc. bowls) mounted below the filter head requires minimal clearance to remove the element for replacement and contaminated fluid cannot be washed downstream when element is serviced. HYDAC Differential Pressure Indicators have no external dynamic seal. This results in a high system reliability due to magnetic actuation, thus eliminating a potential leak point. A poppet-type bypass valve located in the filter head provides positive sealing during normal operation and fast opening during cold starts and flow surges. (Optional non-bypass available) For special finishes and coatings - consult HYDAC for minimum quantities, availability and pricing. Fatigue pressure ratings equal maximum allowable working pressure rating

Specifications Bun

High Pressure

Specifications Cap Material

Steel

Specifications Division

HYDRAULIC AND LUBE FILTERS

Specifications Filter Type

Inline mount 4 mounting holes

Specifications Indication Type

W = no indicator, port is not drilled

Specifications Model Code Description

DF240SETXXW1.0/V-S0184

Specifications Port Configuration

Manifold

Specifications Port Connection

1 1/4 "

Specifications Product

FILTERS-HIGH PRESSURE (>3000PSI)

Specifications Product Group Family

FILTERS-HIGH PRESSURE (ò3000 PSI)

Specifications Seals

Fluorocarbon Elastomer (FKM)

Specifications Size

240

Specifications Type

High Pressure Filter

Specifications Type Number

1

Specifications Weight

11.84 kg | 26.1 lb

Supplementary Details 0

G-1/2 Drain in Bowl Option For Sizes 60 - 280

Technical Specifications Burst Housing Pressure Rating

1180 bar | 17110 psi

Technical Specifications Bypass Valve

Non-Bypass

Technical Specifications Construction Material For Head

Ductile iron

Technical Specifications Element K Factors

0.373

Technical Specifications Fatigue Housing Pressure Rating At 1 Mi

420 bar | 6090 psi

Technical Specifications Flow Capacity

63 gpm | 240 L/min

Technical Specifications Flow Direction

Inside - Outside

Technical Specifications Fluid Compatibility

Compatible with all hydrocarbon based, synthetic, water glycol, oil/water emulsion, and high water based fluids when the appropriate seals are selected.

Technical Specifications Maximum Allowable Housing Working Press

420 bar | 6090 psi