Industrial Air Velocity Sensor Array for Conveyor Systems

Industrial Air Velocity Sensor Array for Conveyor Systems

SKU:AIR-f18317

Enhance product quality and optimize airflow with our precise Air Velocity Sensor Array for ovens & tunnels.

Regular price

$2,499.99

Regular price

Sale price

$2,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Optimize airflow control and product quality with our 1500mm Conveyor Width Air Velocity Sensor Array. Designed for both radiant and convection ovens, this array ensures precise heat delivery. The SCORPION® 2 system offers detailed airflow patterns, side-to-side variation analysis, and real-time data for quality assurance, equipment optimization, and food safety compliance.

Product Specifications

Additional Information

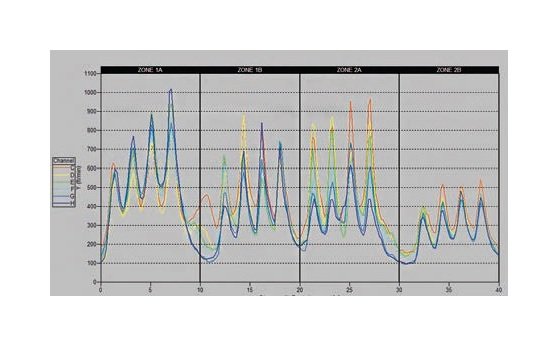

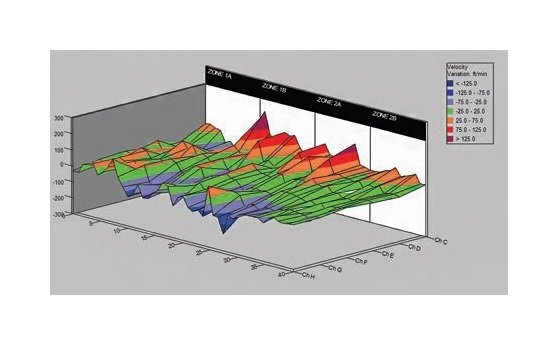

The SCORPION® 2 Air Velocity Sensor Array delivers a precise picture of airflow patterns inside an oven, dryer or cooling tunnel, from side-to-side and end-to-end. Air Velocity Sensors are evenly spaced across the length of a bar, which is selected to match the width of the conveyor. The fixed position sensors collect data, at product level, as the array passes through the process and displays the results in m/sec or ft/min. The number of sensors varies with the length of the bar / conveyor width.Analyzing the ResultsEach sensor output is the sum of air velocity components from all directions, and can be displayed as a line (channel) in a 2D Line Graph. Side-to-side airflow variation is directly related to side-to-side variation in product bake, and represents a critical measurement displayed by the Air Velocity Sensor Array. The tighter the pattern of lines, the more even the air distribution is across the width of the process. Visually, side-to-side variation is better displayed in a 3D Mesh Graph, which in this example is showing greater than 1.2 m/sec (250 ft/min) airflow variation in several areas of the oven. The Air Velocity Sensor Array can help you spot airflow differences between baking zones, concentrated air velocities on isolated parts of the conveyor, and unwanted air currents at the entrance or exit of the oven. Air Velocity Profiles are useful in adjusting your process to maximize quality and reduce waste.

Applications

Quality AssuranceRecord your processing conditions when your product quality is within specification. Save these profiles for future reference as "target" conditions. Use the SPC function included in the software to establish upper and lower control limits for your process temperature, air velocity, heat flux and humidity profiles.Line Start-upTake a SCORPION® 2 profile a few minutes before introducing product into a process. This is a good check that the process has reached the correct operating conditions before production is started.Product Consistency Line-to-LineCompare SCORPION® 2 profiles for two process ovens, perhaps in different factories, that are supposed to be making the same product.Commissioning and MaintenanceHeat process ovens usually include dampers and other controls that must be set by the installation engineer. Use SCORPION® 2 to check that these have been set correctly. Repeat the profiles as part of your preventative maintenance program to detect drift in zone conditions and to pin-point the cause of problems when they do occur.Analyze Equipment PerformanceMost oven manufacturers now use SCORPION® 2 to design their heat processes. This is an invaluable tool for design engineers to balance heat and airflow across the width and along the length of the process oven.Optimize Food Safety and ThroughputControlling internal food temperature is key to achieving food safety. Today's food processors must also document how they are meeting food safety requirements with data. The SCORPION® 2 Data Logging Measurement System makes both jobs easier.The SCORPION® 2 Data Logger with R&D Smart Sensor and Product Probes simplifies the measurement of environment temperature, airflow, energy transfer and internal product core temperature. Plus the SCORPION® 2 Software (SV8) calculates and displays the % kill for a specified pathogen reduction level.By combining this ease of measurement with robust data capture, the SCORPION® 2 System enables better process optimization. No other system makes achieving desired levels of food safety and throughput so simple.New Product DevelopmentUse SCORPION® 2 to record the processing conditions you develop in the lab or in a pilot plant. Then use SCORPION® 2 again to establish the same conditions as the new product is transferred to a full-scale production line.

Standard Array Configurations Bar Length

1450 mm | 57.06 in

Standard Array Configurations Conveyor Width

1500 mm | 59.06 in

Standard Array Configurations Number Of Sensors

13

Standard Array Configurations Sensor Spacing

117 mm | 4.56 in

Technical Summary Battery Running Time

For 1 to 5 Sensors: 7+ hour | For 11 to 15 Sensors: 2+ hour | For 6 to 10 Sensors: 3+ hour

Technical Summary Direction Of Measurement

Omnidirectional

Technical Summary Full Scale Accuracy

5 %

Technical Summary Number Of Sensor Elements Channels

0 to 15

Technical Summary Operating Temperature Range

-50 to 350 ºC | -58 to 662 ºF

Technical Summary Range

0 to 10 m/s | 0 to 1969 ft/min

Technical Summary Reading Resolution

~2 %

Technical Summary Sensor Type

Miniature Hot-Wire Anemometer using Type T Thermocouples