Inovatec 200L Vibratory Deburring Machine - VBS(B) Series

Inovatec 200L Vibratory Deburring Machine - VBS(B) Series

SKU:MAS-8e1891

Achieve precision deburring with Inovatec 200L Vibratory Deburring Machine - VBS(B) Series. Perfect for diverse workpieces.

Regular price

$5,499.99

Regular price

Sale price

$5,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

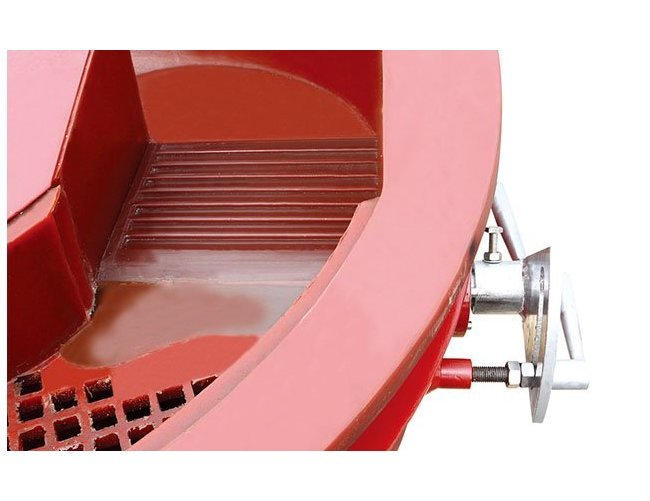

The Inovatec VBS(B) Series 200 Liter Total Volume Vibratory Deburring Machine is a high-performance solution for deburring and edge radiusing various workpieces. Featuring a hot-poured PU design with a heavy-duty vibration motor sourced from leading suppliers, this machine ensures consistent and efficient finishing results. With optional settings like a sound cover and compound dosing pump, along with advanced features such as digital process timer and stress-relieved construction, it offers unmatched versatility and precision in vibratory deburring processes. Ideal for institutional and government buyers seeking cost-effective finishing solutions with long-term reliability.

Product Specifications

Additional Information

Inovatec offers continuous feed and batch feed variants of vibratory deburring machines. The unload flap and separation screen allows quick separation of workpieces from the tumbling media. Our VBS(B) series machine has an extended separation deck with multiple separation holes.

Features

Hot-poured PU and a heavy-duty vibration motor are the primary components in our high-performance vibratory deburring machines. We make our polyurethane using raw materials sourced from Dow Chemicals, USA.We use an automatic casting machine to solidify the PU, then cure it at a controlled temperature for 24 hours. We use heavy-duty motor from Shanghai Vibration Co. With proper maintenance, it can last more than five years.You can use our vibratory de-burring machines VBS(B) to do the following:Remove sharp edgesEdge breakingRemove visible burrsRemove projections at a specific magnificationEdge rounding

Features And Applications

Digital process timerLow profile designWide opening for big size partsStress relieved and enhanced with blastingDefault manual parts media separationExtended separation deckWear resistant PU lining from Dow Chemicals

Optional Settings

Optional ItemsSound CoverCompound Dosing PumpPneumatic flap controlVariable Frequency DrivesControl box standing on the floor or hang on the wall

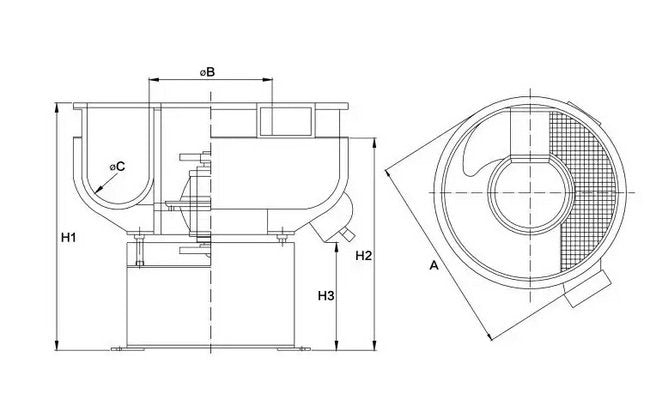

Specifications Bowl Tunnel Width C Diameter

252 mm

Specifications Machine Height H1

940 mm

Specifications Maximum Overall Dimension A

1200 mm

Specifications Media Unload Height H3

360 mm

Specifications Motor Installation Tube Diameter B

530 mm

Specifications Motor Power

3.0 kW

Specifications Total Volume

200 L

Specifications Unload Height H2

770 mm

Specifications Unload Width

250 mm

Specifications Weight

460 kg