Inovatec MV Series Aluminum Wheel Polishing Machine

Inovatec MV Series Aluminum Wheel Polishing Machine

SKU:MAS-83fa5a

Achieve impeccable surface finishing with the Inovatec MV Series Aluminum Wheel Polishing Machine.

Regular price

$5,999.99

Regular price

Sale price

$5,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Inovatec MV Series Aluminum Wheel Polishing Machine is a state-of-the-art vibratory finishing machine designed for high-quality surface finishing of aluminum wheels and parts. With two high-speed vibratory motors and optional settings like variable frequency drive and dosing pump, this machine offers uniform polishing for a range of applications including car wheels, motorcycle wheels, medical parts, and more. It operates efficiently for 24 hours continuously, ensuring exceptional results without damage or impingement. Clean, refurbish, and polish your wheels effectively with this advanced mass finishing solution.

Product Specifications

Additional Information

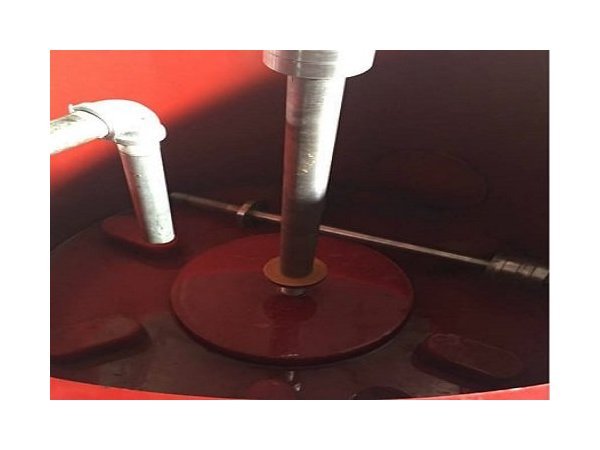

Are your car or bike wheels full of scratches? Or do they have a stubborn dull film which makes them look ugly? Then the wheel vibratory finishing machine is for you.The automatic aluminum wheel polishing machine is designed for wheel smoothing and polishing. This machine can also be used for old wheel refurbishing and cleaning. The suitable wheel size starts from 14′ to 32′ including the motorbike wheel, car wheel, truck wheel and also.Inovatec offers wheel fixing device that retains the parts tightly to the bottom of the bowl chamber. The process time takes several hours for one process.The wheel vibratory finishing machine is an excellent and effective mass wheel polishing and burnishing machine. The machine works best on aluminum wheels and parts. You can get rid of scratches and unpleasant film from your vintage wheels easily using this machine.Here’s the best part about using this machine:You are not restricted to finishing small car wheels alone. You can also polish big wheels - truck wheels that are about 32’’.Why is it essential to polish your aluminum wheels?Well, these wheels spin at incredibly high speeds under a lot of pressure. If these wheels develop any form of weakness, they might cause a tragic accident by snapping.This machine is effective and efficient because it polishes your parts and wheels in low amplitude. The low amplitude polishing curbs damage of your wheels a great deal.This machine is a product of Inovatec Machinery. It is designed to cater for all the automotive finishing you may need.Its services range from polishing alumina wheels to huge truck wheels. It works excitingly:The target wheel is affixed at the bottom of the machine, and finishing media is added together with the necessary finishing compounds.This machine cleans even the most intricate corners of your wheels. How?The machine is designed to ensure that the flow of finishing abrasives is effective and systematic when moving around the target wheel.Bottom line:The wheel vibratory polishing and buffing machine are effective and highly efficient.Check out some of its cool features:Firstly, its finishing chamber is equipped with first-class PU lining. It also has two conduits that drain water or already used finishing compounds out of the machine.Secondly, this machine does not restrict you to a particular wheel size that you can polish. You can clean big truck wheels with ease. You can also polish motorcycle wheels as well as small motorcycle parts.The third cool feature is the inlet jet - a standard for all-wheel vibratory finishing machines. It helps you dispense finishing chemicals and water quickly.The machine also has a variable speed control - you can change the amplitude of the wheel vibratory finishing machine. This speed variable control is particularly great with parts with complex structures and corners that are difficult to reach.The machine also finishes your parts rapidly because it has more than one finishing motor. It can have two or a maximum of three motors. Since these motors generate incredible power, the machine can work continuously and produce impeccable results.The machine is relatively easy to operate because it has a pretty straightforward control panel. With this control panel, you can set all the necessary finishing parameters. You can also alter these parameters if a change is required during the finishing process.

Applications

Aluminum wheel polishingMotorcycle wheel polishingMedical parts polishingPropeller polishingUniform FinishingHigh productivity24 hours continuous running

Optional Settings

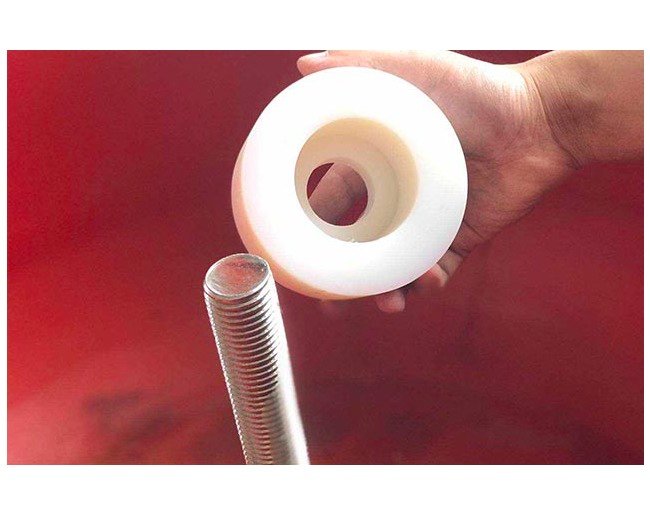

Dosing pumpVariable frequency drive3 motorsSpecially designed fixing device for parts

Specifications Wheel Material

Aluminum