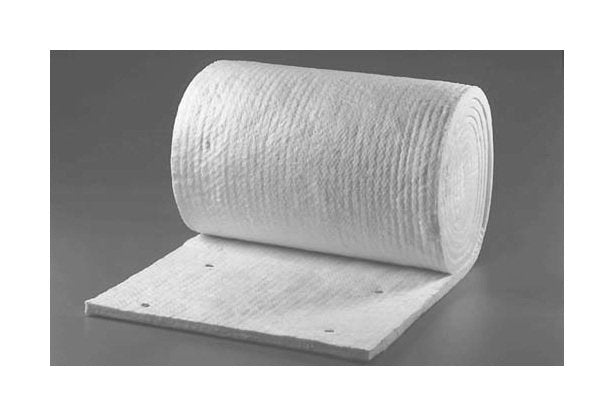

Insulfrax® S Blankets

Insulfrax® S Blankets

SKU:INS-08fe26

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Insulfrax® S Blanket from Unifrax was developed from a calcium, magnesium, silicate chemistry to provide thermal insulation at continuous operating temperatures up to 2012 ºF (1100 ºC). Insulfrax® S Blanket also meets European regulatory requirement (Directive 97/69/EC). Insulfrax® S fiber chemistry has been combined with Unifrax's proprietary fiber spinning technology to create a specialty high temperature blanket with superior thermal and mechanical properties.Insulfrax® S blanket is used in a wide range of applications including refractory linings, thermal insulation, appliances, and molten metals transfer.

Product Specifications

General Characteristics

Insulfrax® S Blanket is a flexible, strong, lightweight, needled blanket produced from Insulfrax® Fiber. Mechanical needling of the spun Insulfrax® fibers eliminates the need for binders in the product's manufacture and results in a product with high tensile strength. Since Insulfrax® S Blanket is completely inorganic, the product exhibits no smoke generation or outgassing in service.Insulfrax® S Blanket combines low thermal conductivity with excellent resistance to thermal shock. Note that high humidity and wetting with water prior to service has little effect on Insulfrax® S Blanket.A series of green dots on the surface of the blanket make identification, tracking, and inspection of Insulfrax® S Blanket simple on the job site or in the fabrication shop.The Insulfrax® Fiber calcium, magnesium, silicate chemistry provides superior wetting resistance to molten aluminum alloys. Testing with corrosive aluminum alloys at elevated temperatures has proven that Insulfrax® fibers are superior to traditional alumina/silica refractory ceramic fibers.

Health And Safety Information

Insulfrax® Thermal Insulation from Unifrax, according to Directive 97/69/EC, possesses a fiber chemistry within the regulatory definition of a "man-made vitreous (silicate) fiber with random orientation with alkaline oxide and alkaline earth oxide content greater than 18% by weight." Insulfrax® fibers have been tested pursuant to EU protocol ECB/TM/26, Revision 7, Nota Q, Directive 97/69/EC, with results that are below regulatory thresholds. As a result, Insulfrax® Thermal Insulation does not require additional labeling or further testing. Refer to the product Material Safety Data Sheet (MSDS) for recommended work practices and other product safety information.

Note

Non-standard sizes are available by contacting Unifrax customer service.For additional information about product performance or to identify the recommended product for your application, please contact the Unifrax Application Engineering GroupData are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes.

Product Applications Applications

Insulfrax® S Blanket is classified by Underwriters Laboratories (UL), per UL 723 (ASTM E-84). Flame Spread Rating = 0, Smoke Developed Rating = 0. High tensile strength and excellent thermal properties combine to make Insulfrax® S Blanket the product of choice for a wide range of applications in a number of industries:AppliancesResidential self-cleaning ovensHigh-temperature commercial cooking appliancesHearth ProductsChimney InsulationPrimary MetalsExpansion joint sealsAluminum transfer ladle coversBackup insulation for dense refractory liningsBackup insulation for refractory ceramic fiber or Isofrax® liningsMaintenance blanketHeat shieldsMetals ProcessingStress relieving blanketsSeals and gasketsPetrochemical/PowerReusable insulating padsExternal boiler and duct insulationCeramic and GlassGlass tank crown insulationExpansion jointsCarbon baking furnace covers

Product Forms Standard Density

4 lb/ft³ | 6 lb/ft³ | 8 lb/ft³

Product Forms Standard Length

12.5 ft | 25 ft

Product Forms Standard Thickness

0.5 in | 1 in | 1.5 in | 2 in

Product Forms Standard Width

24 in | 48 in

Product Parameters Average Fiber Diameter

3.0 to 5.0 µm

Product Parameters Chemical Analysis Calcium Oxide Cao

27 to 33 %

Product Parameters Chemical Analysis Magnesium Oxide Mgo

2 to 7 %

Product Parameters Chemical Analysis Other

< 1 %

Product Parameters Chemical Analysis Silicon Dioxide Sio

61 to 67 %

Product Parameters Fiber Index

55 to 60 %

Product Properties Average Tensile Strength At 4 Pounds

4 psi

Product Properties Average Tensile Strength At 6 Pounds

5 psi

Product Properties Average Tensile Strength At 8 Pounds

7 psi

Product Properties Color

White

Product Properties Melting Point

1310 ºC | 2390 ºF

Product Properties Recommended Operating Temperature

1100 ºC | 2012 ºF

Product Properties Specific Gravity

2.67 g/cm³

Product Properties Specific Heat At 1000 Degree Celsius

1000 J/kg·K

Product Properties Temperature Grade

1260 ºC | 2300 ºF