LEIBINGER JET3up Pro Industrial CIJ Printers

LEIBINGER JET3up Pro Industrial CIJ Printers

SKU:JET-1c65ce

Enhance product traceability and efficiency with LEIBINGER JET3up Pro CIJ Printers for high-speed non-contact marking.

Regular price

$8,499.99

Regular price

Sale price

$8,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The LEIBINGER JET3up Pro Industrial Continuous Inkjet Printers offer versatile non-contact marking on various surfaces at production speeds up to 10 m/s. With fast-drying inks, flexible font options, and robust stainless steel construction, these printers ensure high-quality, precise printing for expiration dates, barcodes, serial numbers, and more. Featuring automated nozzle sealing, low maintenance, and 100% availability, they are ideal for industries with strict hygiene standards and high production demands.

Product Specifications

Accessories Accessories

Product detector, shaft encoders, printer stand, print head bracket, alarm lamps etc.Software for remote control, multi-head control

Additional Information Additional Information

Do You NeedA fast and easy method for flexibly marking products in wet and/or dusty environments?An uncomplicated marking system with protection class IP 65 without hidden costs?German name brand quality and engineering service?Are You Tired ofLosing valuable production time because your inkjet printer is not available, the printhead has to be cleaned or the ink is dried out in the printhead?Being unable to sell your products due to faulty or poor-quality coding or even having it result in expensive recall measures?Your operating costs constantly rising due to the high cost of consumables, energy and service?Do You ExpectA robust, high-performance and 100% reliable marking solution for wet, dusty and rough production environments?A wide range of practical functions that ease your everyday production and automation?Fast, fair and transparent service - worldwide?

Advantages Advantages

100% protection against dust and spray waterProtection class IP65. Robust stainless steel housing, integrated head ventilation. No hidden dirt traps. Meets high hygiene requirements of the pharmaceutical and food industries.Maintenance-free starting without cleaning - guaranteed!Automated Sealtronic nozzle seal. No drying out of ink in the printhead. Ready to print immediately, even after long shut-down periods.Reliable productionConsistent prevention of downtime. No daily service work, no forced stops due to scheduled service intervals. 100% availability.Maximum print quality, wide range of applicationsAccurate placement of ink drops using Drop Position Control. High-precision and high-contrast printouts. Static and variable data such as technical data, special characters, serial numbers, barcodes, 2D codes, graphics and much more.No wait times - ready for operation immediatelyThe Clean Instant Start and Stop Technology is used to make the JET3up PRO ready for printing in only a few seconds. Always a clean printhead with any number of start and stop cycles.More than 2,000 products/minuteMarking up to 10 m/s (36 km/h)!Intuitive operationEasy and fast, like your computer at home. Color 10.4" touch-screen display. Windows-based, customizable user interface. Optimized menu navigation.Low operating costsNo solvent consumption during production shutdowns using Sealtronic. Low maintenance costs. No replacement of expensive modules.Countless functions without additional costsAll interfaces and over 800 software functions are standard. Easy integration into the production line. Free lifetime software updates!

Data Administrationsecurity Data Administrationsecurity

Data buffer in case of power failureFile ExplorerPrint jobs saved with printing data and machine parametersPrinter data logging, production run loggingUp-and download of jobs and graphics using USB stick or networkJob select (1023 jobs selectable from scanner or PLQ

Fluid Reservoirs Fluid Reservoirs

Capacity of the ink and solvent tanks are 1.3 liters, refillable while printingLevel gauge with fully automated monitoringRemaining prints are displayed

Inks Inks

Fast-drying solvents inks (<1sec)Various pigmented contrast inksMEK-free, ketone-free and alcohol-based inksTemperature and transfer-resistant inksPVC inks (vinyl inks)Halogen-free inksSpecial inks, such as security, color changing, sterilization, washable adhesive, alcohol-resistant and UV fluorescent inksFood-grade ink and food packaging inksCustom special inksAvailability depends on the printer model.

Interfaces Inputsoutputs Interfaces Inputsoutputs

Product detector PNP/NPN 24V, FIFO bufferShaft encoder input for printing speed synchronization (TTL 5V, HTL 24V, RS422, 5V)9 digital inputs and 8 outputs, user-selectablePrinter alarm, low fluid, print ready, print finished, external job | selection etcSerial interface RS232 up to 115200 baudUSB portEthernet (industry standard M12D), script protocolSensor for product monitoring and speed measurementOption: Special interface to connect several printers

Leibinger Hydraulic System Leibinger Hydraulic System

Low maintenance, diaphragm pumps with optimized run timeFully automatic viscosity and pressure controlThermally isolated hydraulicsAutomatic monitoring of compressed airAutomatic daily interval function (Auto ink circulation)Integrated cabinet ventilation

Operationdata Input Operationdata Input

10.4" color TFT touch-screen display (SVGA)Creating and editing jobs during productionCustomizable user interfaceIntegrated font and graphic editorIllustrated operator instructionsAlternative control using the data interface (serial or Ethernet)Country-specific on-screen key padOperational available by mouse or keyboardComprehensive self-diagnostics and status display with easy-to-understand text, help function, printer status displayStorage of numerous jobs and graphicsPassword function and service menuWindows based interface, WYSIWYG, real-time updating of displayRemote control over VNC

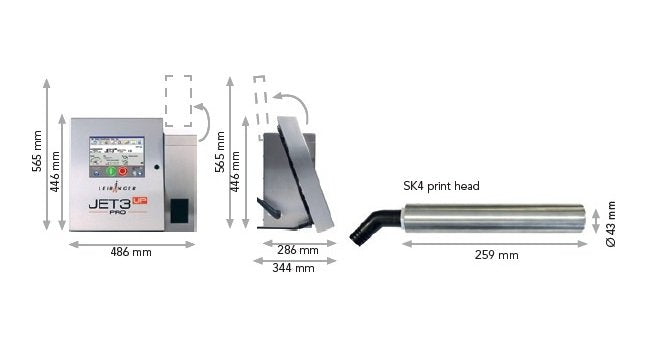

Print Head Print Head

Fully automatic nozzle and gutter seal "Sealtronic"Fully automatic drop charging, drop break off controlNozzle size from 35 to 70 pm, depending on the modelUpside down - 360° operationSafety switch for print head lockingHead ventilation, options: 45° to 90° bent umbilical, various print head versionsAutomatic inkjet monitoring

Print Performancefunctions Print Performancefunctions

Fonts and graphics can be positioned and combined in the print jobs as desiredProportional function for all fontsFont height and font width adjustableAll major barcodes and DataMatrix codes (ECC200),GS1 DataMatrix (EAN/ECC), QR-Code, PPN-CodeTime, auto-adjustable date, auto-adjustable expiration date, weekdays, calendar weeks, Julian calendar, shift identificationReplacements: all date, time and counter functions can be replaced and user-programmed32 individually programmable counters, consecutive numbering, production counter, meter marking with "Meter Go" functionUser-programmable graphics/logos can be created in the integrated editorMulti-stage contrast and bold function, print repetition, print delay, backward print, rotation/mirroring of font, inverse, reverse and alternating prints (object-related)Dynamic backward printing, for traversing linesProgrammable batch production and interlinking of multiple jobsExternal text function via scanner or data interfacePrinting variable data from external files via USB stick or data interfaceStop function after reaching preselected valueProduct jam detection / monitoring of product alignmentAutostart functionPrompt function (fast edit)Solvent Saving ModeSelf-test function

Technical Specs Available Menu Languages

Arabic | Chinese | Cyrillic | European languages | Korean | Persian, etc. | Thai | Vietnamese

Technical Specs Cabinet Material

Stainless Steel

Technical Specs Cabinet Weight

20.5 kg

Technical Specs Compressed Air Consumption

100 L/min

Technical Specs Country And Industry Specific Fonts

Arabic | Chinese | Cyrillic | Persian, etc.

Technical Specs Current

20 A

Technical Specs Flexible Umbilical Length

3 m

Technical Specs Fonts

From 5 x 5 to 32 x 20, special fonts, user-programmable fonts, tower printing

Technical Specs Frequency

50 to 60 Hz

Technical Specs Ingress Protection Ip Rating

Ingress Protection (IP65)

Technical Specs Ink Colors

Black | Blue | Gray | Green | Orange | Red | Silver-Gray | White | Yellow

Technical Specs Maximum Non Condensing Relative Humidity Rh

90 %

Technical Specs Multi Line Fonts

1 to 5

Technical Specs Note For Printing Height

Depending on nozzle size, head and printer type

Technical Specs Optional Flexible Umbilical Length

10 m | 6 m

Technical Specs Printing Height

0.8 to 16 mm

Technical Specs Printing Speed

Up to 10 m/s | Up to 600 m/min

Technical Specs Print Head Weight

1.5 kg

Technical Specs Required Inlet Pressure

1.4 bar

Technical Specs Temperature Range

5 to 45 ºC

Technical Specs Voltage

100 to 240 V

The Automated Sealtronic Nozzle Seal Is One Of A Kind The Automa

Due to its accurate precision engineering.In its operating principle.In its effectiveness.LEIBINGER printhead with nozzle sealShut down processThe gutter is moved to the nozzle automatically when shutting down the printer, forming a hermetically sealed, airtight circuit. The result: 100% secure protection from ink drying out!Startup ProcessFirst, the ink begins to flow in the sealed circuit creating a stable ink stream. The gutter then opens automatically. This happens within a few seconds and guarantees a fast and error-free start. The printhead remains absolutely clean in this process.Conventional printhead without nozzle sealShut down processNozzle and gutter remain open. The residual ink is exposed to the air unprotected and dries out. This causes problems the next time the printer is started.Startup processThe conventional design causes an unstable startup of the jet. The result: the printhead gets dirty regularly and thus drop charging is degraded right from the start.The advantages for productionImmediate, reliable startingNo delays in the start of productionNo cleaning cycle requiredNo production interruptionsLong availability - typically months between cleanings