Magnetic Particle Brake - 50W Heat Dissipation, 1800 RPM

Magnetic Particle Brake - 50W Heat Dissipation, 1800 RPM

SKU:SMA-76a352

High-performance Magnetic Particle Brake for precise torque control in tension and load applications.

Regular price

$249.99

Regular price

Sale price

$249.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The 50W Slip Heat Dissipation Magnetic Particle Brake offers precise torque control ideal for tension control, load simulation, and soft stops. With a torque range of 1 to 60 lb-in and a maximum speed of 1800 rpm, this self-contained brake ensures smooth and repeatable performance. Designed for reliability and efficiency, it features shaft configurations for versatile installation and comes with options for different DC coil voltages. Whether for unwinding webs or torque limiting applications, this brake provides exceptional control and reliability.

Product Specifications

Characteristics Characteristics

With no electrical excitation, the shaft freely rotates.With electrical excitation, the shaft becomes coupled to the case.While the load torque is less than the output torque, the shaft wonât rotate.When the load torque is increased, the brake will slip smoothly at the torque level set by the coil input current.

Determining Proper Brake Size Determining Proper Brake Size

Determining Proper Brake SizeThe proper sized brake mustâ¦Have sufficient torqueBe able to dissipate the heatNo run above rated speedTorqueFor load simulation, torque limiting and similar applications, torque is already known.For web handling, torque must be calculated. First determine the desired tension in your web (wire, fabric, film etc.).Calculate Torque: Torque (lb-inches) = Tension (lbs) x Roll Diameter (inches) x 0.5Use the Full Roll Diameter for calculating the maximum torque needed. For applications with the web running over a pulley or between nip rollers (pinch rollers), use the pulley diameter as the roll diameter in the formula above. Always be conservative - select the next larger model if the application requires nearly the rated torqueRPM (must be less than the maximum allowable)For load simulation, torque limiting and similar applications, RPM is already known.For web handling, usually linear speed (Web Speed) is known, and RPM must be calculated.Calculate RPM: RPM = 3.8 x WEB SPEED (feet per minute)/ROLL DIAMETER (inches)Use the Full Roll Diameter to determine the slowest speed. Use the Core Diameter (empty spool diameter), to determine the fastest speed. For applications with the web running over a pulley or between nip rollers (pinch rollers), use the pulley diameter as the roll diameter.Slip Heat Dissipation (model must be physically large enough not to overheat)For any application.Calculate Heat Input: HEAT (watts) = TORQUE (lb-inches) x RPM x 0.012For unwinding applications.Calculate Heat Input: HEAT (watts) = WEB TENSION (lbs) x WEB SPEED (feet/minute)/44Duty CycleThe average heat input must be below the brake's heat dissipation rating. If the motion is intermittent, use the average speed for thermal (SLIP) calculations.

Note Note

Mounting holes - Standard: Imperial (inch), Optional: Metric

Specifications Available Direct Current Dc Coil Voltage

6 V | 12 V | 24 V | 90 V

Specifications Configuration

Shaft on 1 side with 2 flats or with flat and keyway, hollow shaft

Specifications Maximum Overhung

100 lb | 450 N

Specifications Maximum Speed

1800 rpm

Specifications Slip Heat Dissipation

50 W

Specifications Torque Range

1 to 60 lb·in | 12 to 680 N·cm

Specifications Weight

7 lb | 3.1 kg

Torque Torque

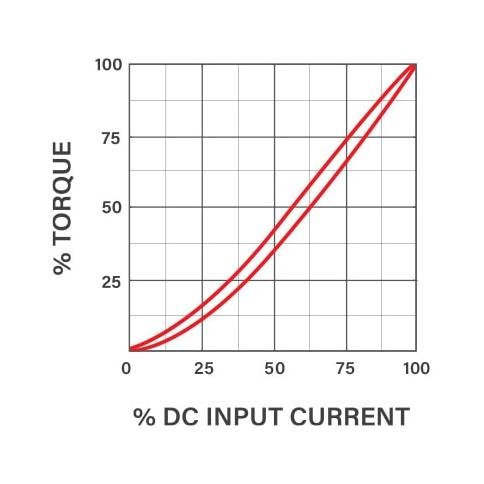

Is proportional to input current.Is independent of RPM.

Applications Applications

Adjustable Tension - For Unwinding (Payout) Webs.Load Simulation - For Testing Stepper Motors, Gear Motors and MechanismsTorque LimitingSoft Stops