MK Magnetics C-Core - 0.001" Typical Thickness

MK Magnetics C-Core - 0.001" Typical Thickness

SKU:CCO-b5d079

Achieve precision and reliability with the MK Magnetics C-Core. Customizable with tight tolerances for low noise applications.

Regular price

$29.99

Regular price

Sale price

$29.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

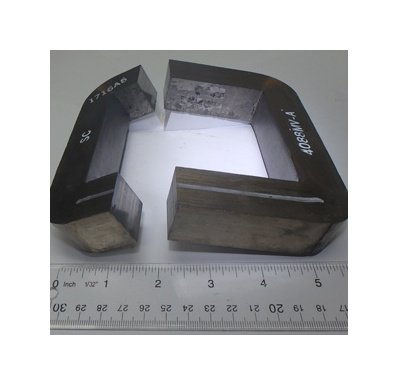

The MK Magnetics C-Core with a standard grade of 3% grain-oriented silicon steel and a typical thickness of 0.001 inches offers unparalleled performance in magnetic applications. Customizable to meet various needs, this core features multiple cuts, special air gap cuts, and tighter tolerances required for low noise applications. With diamond-lapped mating surfaces, high temperature heat stabilization processes, and epoxy coating, this core meets the stringent standards of industries requiring precision and reliability.

Product Specifications

Additional Information Additional Information

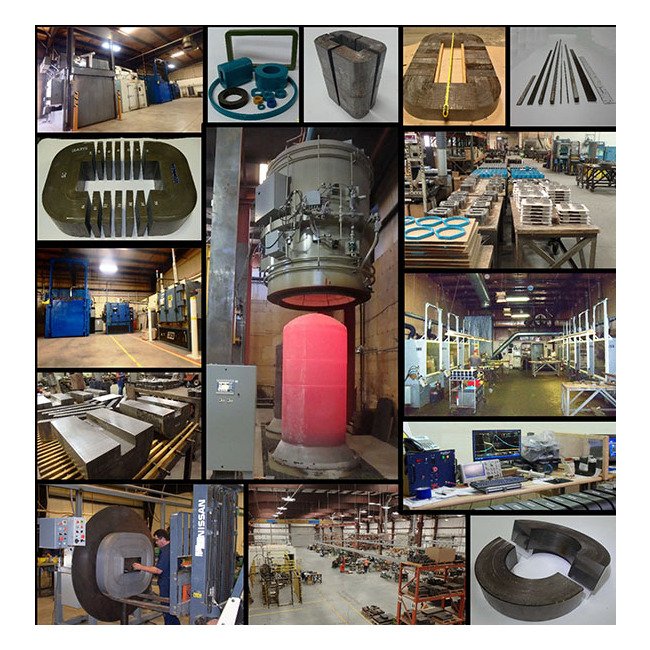

MK Magnetics will gladly manufacture cores to your specific dimensional and physical requirements such as: non-standard mechanical tolerances, multiple cuts, or diamond lapped for lowest possible excitation and/or acoustical noise.

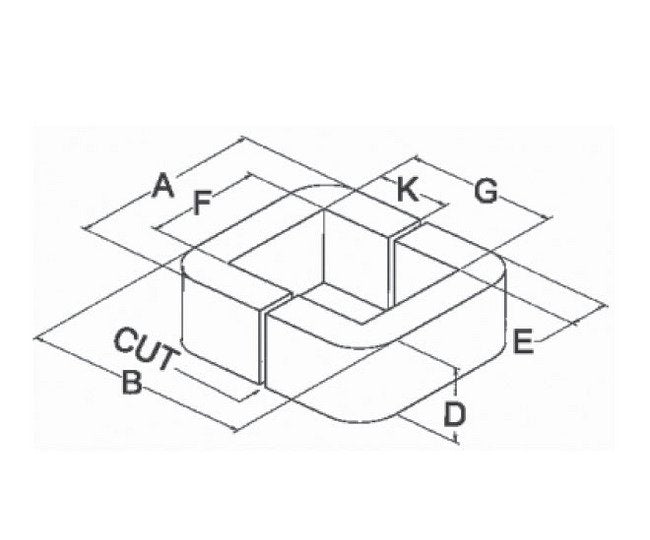

Dimensional Tolerances For Cut C Cores Per Eia Standard Rs 217 A

0.031 in. When Outside Core Height (B) < 3.500 in. | 0.062 in. When Outside Core Height (B) ⥠3.500 in.

Dimensional Tolerances For Cut C Cores Per Eia Standard Rs 217 N

A and B dimensions are held to a maximum tolerance only, negative tolerances are controlled by the F, G, and E dimensions. F and G dimensions are held to a minimum tolerance only, positive tolerances are controlled by the A, B and E dimensions.

Features Features

Customizable to Meet your NeedsCustom SizesCustom ShapesMultiple CutsSpecial Air Gap CutsTighter TolerancesLow Noise ApplicationsDiamond-Lapped Mating SurfacesSpecial High Temperature Heat Stabilization ProcessesSpecial Edge ChamferingEpoxy CoatingSpecial Stack Resistance RequirementsSpecial Part MarkingCustom AssembliesCustom Grinding and MachiningSmall Planar-Type Geometries

Note Note

B (kG) is flux density in kilogauss. Watts/lb and VA/lb are power loss and excitation VA when measured at the indicated flux (B) and frequency (Hz) under sine wave excitation. Gap VA for a 0.001" total air gap was calculated using the following formula: Gap VA = 4.1 à 10-4 à B2 à frequency (Hz) à SF2 à Ag. Cores under 25 lbs use 0.001" air gap and those in excess of 25 lbs use 0.002" air gap. Total core watts = material watts/lb à core wgt in lbs. Total core excitation VA = material VA/lb à core wgt in lbs + gap VA.Odd or small core geometry may impact performance.Call for more details about these and other possibilities.

Specifications Core Type

C

Magnetic Performance Guide Industry Standards

EIA Standard RS-217

Magnetic Performance Guide Material

Standard Grade, 3 % Grain-Oriented Silicon Steel, 0.001 in.

Magnetic Performance Guide Material Description

3 % Silicon Steel Silectron®

Magnetic Performance Guide Maximum Excitation

20.3 VA/lb

Magnetic Performance Guide Maximum Power Loss

12.0 Watts/lb

Magnetic Performance Guide Maximum Total Air Gap At 0001

16.3 VA/in²

Magnetic Performance Guide Minimum Space Factor

0.83 in

Magnetic Performance Guide Note For Material

Silectron® is a registered trademark of Allegheny Ludlum Steel Corp.

Magnetic Performance Guide Test Flux Density B

12.5 kg

Magnetic Performance Guide Test Frequency

400 Hz

Magnetic Performance Guide Thickness

0.001 in