MK Magnetics C-Core 0.004 Inch Thickness

MK Magnetics C-Core 0.004 Inch Thickness

SKU:CCO-8fd602

High-performance MK Magnetics C-Core with 0.004" thickness, customizable sizes, and EIA Standard RS-217 compliance.

Regular price

$29.99

Regular price

Sale price

$29.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The MK Magnetics C-Core with a typical thickness of 0.004 inches is a high-performance solution designed to meet the demanding requirements of industrial and government applications. Crafted from Supermendur® with 49% Cobalt, 49% Iron, and 2% Vanadium, this C-Core offers superior magnetic properties. With customizable sizes, shapes, and multiple cutting options, it ensures precise fits for various specifications. From special air gap cuts to low noise applications, this C-Core excels in diverse settings. Additionally, it complies with EIA Standard RS-217, guaranteeing quality and reliability.

Product Specifications

Additional Information Additional Information

MK Magnetics will gladly manufacture cores to your specific dimensional and physical requirements such as: non-standard mechanical tolerances, multiple cuts, or diamond lapped for lowest possible excitation and/or acoustical noise.

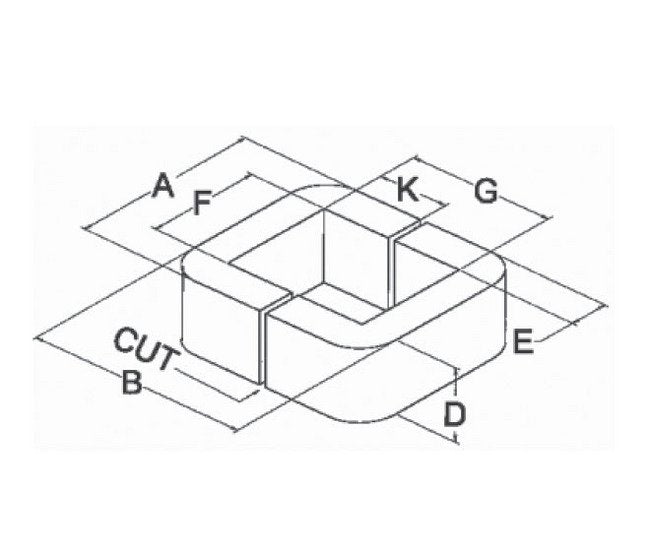

Dimensional Tolerances For Cut C Cores Per Eia Standard Rs 217 A

0.031 in. When Outside Core Height (B) < 3.500 in. | 0.062 in. When Outside Core Height (B) ⥠3.500 in.

Dimensional Tolerances For Cut C Cores Per Eia Standard Rs 217 N

A and B dimensions are held to a maximum tolerance only, negative tolerances are controlled by the F, G, and E dimensions. F and G dimensions are held to a minimum tolerance only, positive tolerances are controlled by the A, B and E dimensions.

Features Features

Customizable to Meet your NeedsCustom SizesCustom ShapesMultiple CutsSpecial Air Gap CutsTighter TolerancesLow Noise ApplicationsDiamond-Lapped Mating SurfacesSpecial High Temperature Heat Stabilization ProcessesSpecial Edge ChamferingEpoxy CoatingSpecial Stack Resistance RequirementsSpecial Part MarkingCustom AssembliesCustom Grinding and MachiningSmall Planar-Type Geometries

Note Note

B (kG) is flux density in kilogauss. Watts/lb and VA/lb are power loss and excitation VA when measured at the indicated flux (B) and frequency (Hz) under sine wave excitation. Gap VA for a 0.001" total air gap was calculated using the following formula: Gap VA = 4.1 à 10-4 à B2 à frequency (Hz) à SF2 à Ag. Cores under 25 lbs use 0.001" air gap and those in excess of 25 lbs use 0.002" air gap. Total core watts = material watts/lb à core wgt in lbs. Total core excitation VA = material VA/lb à core wgt in lbs + gap VA.Odd or small core geometry may impact performance.Call for more details about these and other possibilities.

Specifications Core Type

C

Magnetic Performance Guide Industry Standards

EIA Standard RS-217

Magnetic Performance Guide Material

Supermendur®, 49% Cobalt, 49% Iron, 2% Vanadium, 0.004, Round, Square Loop.

Magnetic Performance Guide Material Description

50 % Cobalt-Iron Supermendur®

Magnetic Performance Guide Maximum Excitation

66.0 VA/lb

Magnetic Performance Guide Maximum Power Loss

19.0 Watts/lb

Magnetic Performance Guide Maximum Total Air Gap At 0001

58.6 VA/in²

Magnetic Performance Guide Minimum Space Factor

0.90 in

Magnetic Performance Guide Note For Material

Supermendur® is the discontinued product name of Carpenter Technology.

Magnetic Performance Guide Test Flux Density B

21.0 kg

Magnetic Performance Guide Test Frequency

400 Hz

Magnetic Performance Guide Thickness

0.004 in