Motor Driven End Truck Kits - UCS Competitor Series

Motor Driven End Truck Kits - UCS Competitor Series

SKU:REL-2d4f01

Enhance crane performance with Motor Driven End Truck Kits - UCS Competitor Series. Precision engineering meets OSHA standards for smooth operation.

Regular price

$2,499.99

Regular price

Sale price

$2,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

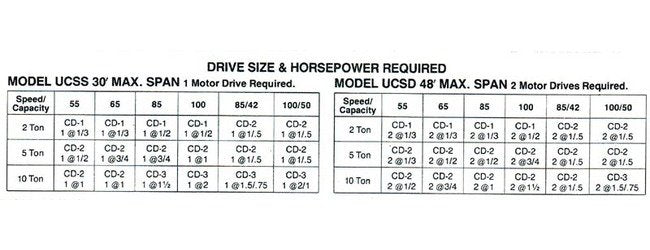

The Motor Driven End Truck Kits from the UCS Competitor Series combine precision engineering with durability to deliver superior performance. Featuring single and dual motor designs with precision oil bath lubricated gearing and mechanical braking, these kits ensure smooth deceleration and stopping, meeting all OSHA requirements. The alloy carbon steel precision-cut gears with large pinion gears and self-aligning lubricated bearings provide long life and quiet operation. Fabricated from steel channel shapes with heavy axle reinforcement, these kits offer true running operation with Tru-Tred Wheels and heavy-duty Timken tapered roller bearings. With a 10-ton capacity and meeting stringent quality standards, these kits are ideal for reliable overhead crane setups.

Product Specifications

Kit Contents 0

Tru-Tred Alloy Steel Wheels Motor Driven Models Heavy Duty sealed tapered tapered roller bearings Precision Machine Cut Steel Gears Large Diameter Drive Pinions

Specifications Capacity

10 Tons

Specifications Crane Wheel Diameter

6 1/2 inches

Specifications Max Runway Rail

S20 x 66.0

Specifications Max Wheel Load Per Pair

14000 lbs.

Specifications Min Runway Rail

S12 x 31.8

Specifications Model

Model UCS Competitor Series

Specifications Net Weight Per Pair

750 lbs.

Specifications Optional Equipment

Controls - Single or two speed | Bumpers - Rubber or spring type | Shorter wheel base | Spark resistant models

Specifications Wheel Base

5'-0"

Standard Features 0

Drives : Single and dual motor design with precision oil bath lubricated gearing and mechanical braking for smooth deceleration and final stop. Standard "Rightway" 230/460V-3P-60Hz drive motors are connected to precision oil bath lubricated gear reducers. The Mechanical Braking meets all OSHA requirements for crane deceleration and stopping. Gearing : Alloy carbon steel precision machine cut, sized and proportioned with large pitch diameter pinion gears having generous face width for long life and quiet operation. Pinion gears are supported between self-aligning lubricated and sealed ball bearing pillow blocks - no overhung gearing.End Truck Frames : Fabricated from steel channel shapes with heavy axle reinforcement bosses, precision drilled bridge girder connection pads and protective front plates with rail safety lugs all jig assembled to insure accurate wheel alignment for true running operation. Split truck design allows quick easy crane erection on either open end or closed end runway system.Tru-Tred Wheels : Precision machined from alloy steel to meet the most demanding service requirements.Wheel Bearings : Heavy duty long life rated lubricated and sealed Timken tapered roller bearings designed to take the unavoidable shocks of crane duty.Side Rollers : Heavy-duty cam follower bearings provide smooth non-skewing crane operation.