MPI™ MARA Series Metal Seat Relief Valve (Factory Set)

MPI™ MARA Series Metal Seat Relief Valve (Factory Set)

SKU:VAL-680486

Reliable MARA Series Metal Seat Relief Valve for precise venting at 5000-10000 psi, factory set and sealed.

Regular price

$99.99

Regular price

Sale price

$99.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

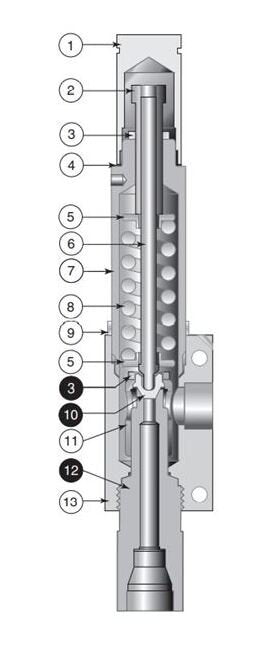

The MPI™ MARA Series Metal Seat Relief Valve is designed for precise venting of gases or liquids at pressures ranging from 5000 psi to 10000 psi. With a temperature range of -423ºF to 400ºF and options up to 750ºF, these valves are ideal for pressure gas systems, cryogenic applications, and more. Not recommended for steam boiler use, they provide accurate relief proportional to pressure increase and offer a relief valve accuracy of +/-3% of setpoint. Factory set and sealed, these valves maintain integrity and performance under demanding conditions.

Product Specifications

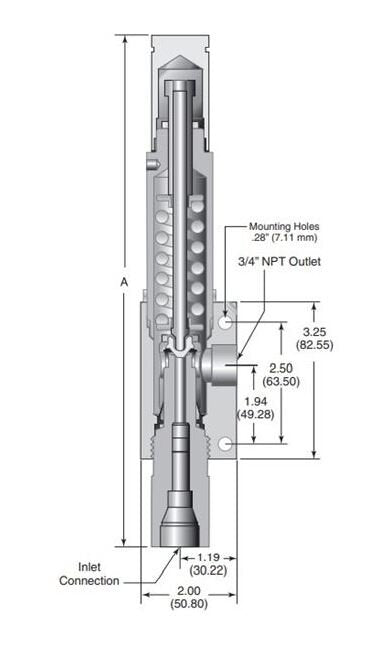

Dimensions A

10.62 in

Dimensions Back Pressure Max

500 psi | 34 bar

Dimensions Connection

MPI™ to FNPT

Dimensions Orifice Diameter

.188 in

Dimensions Pressure Rating Max

10000 psi | 690 bar

Dimensions Pressure Rating Min

5000 psi | 345 bar

Dimensions Repair Kits

R8MARA-10K-2507

Dimensions Size

1/2 x 3/4

Specifications Caution

Parker Relief Valves are preset and factory sealed. Warranty is voided if seal is broken by customer. Maximum system operating pressure should not exceed 90% of relief valve set pressure. Pressures in excess of this value may cause weepage resulting in damage to plug and seat.Care should be taken when locating a relief valve within a piping system to keep the relief valve as far from the pump as possible. Certain pumps create an end-of-stroke spike in pressure that is not detectable by common instrumentation. These spikes could cause premature failure of the relief valve.