OptiDual 106 Inch (in) Width x 157 Inch (in) Length x 53 Inch (in) Height Footprint High Performance Large Format Carbon Dioxide (CO2) Laser Cutting System

OptiDual 106 Inch (in) Width x 157 Inch (in) Length x 53 Inch (in) Height Footprint High Performance Large Format Carbon Dioxide (CO2) Laser Cutting System

SKU:OPT-c59f01

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The OptiDual Laser System was specially designed for customers that require a laser system capable of high production cutting. The second laser is connected to the master laser by an adjustable bar. As the master laser is cutting a part, the second laser will be cutting the same part just inches away. Both lasers output power can be matched within the KCAM® software. This ensures that the parts being produced are similar in size, accuracy and quality.The OptiDual's Y axis is powered by Kern's HyperDual motion package. Capable of cutting and marking metals such as stainless steel, aluminum, mild steel and thin brass; and non-metals such as fabrics, plastics/acrylics, wood, stone, glass, rubber, printed materials, etc This machine can also be equipped with our Camera Vision System, Rotary, and/or our pen marking system.

Product Specifications

Additional Features

UL Electrical PanelA UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.Laser Safety GlassesTwo pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ at 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.Laser Tool KitA kit with commonly used tools and consumables makes system maintenance fast and convenient. The kit includes a foam padded box with cuto-uts for each tool, making it easy to identify missing components.2.5" S-focus Lens AssembliesA great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.Solid Steel ChassisThe OptiDual is built around a precision-machined, heavy-duty steel weldment as the machine base. The one-piece weldment allows for the machine to arrive fully assembled, greatly reducing installation time.Honeycomb BedA durable aluminum table structure is inserted into the bed, maintaining a flat work surface. The honeycomb cells allow for a down draft table and also ducting smoke and debris into the bottom table chamber.

Additional Information

This includes high speed servo motors on each side of the table on a rack and pinion setup. The X axis has a linear motor and two precision rails resulting in fast, accurate and smooth cutting performance.With two lasers mounted on a single gantry, it allows operations to double their production.A Powerful Tool Capable of High Production Cutting.

Dimensions Footprint Height

53 in | 1346 mm

Dimensions Footprint Length

157 in | 3988 mm

Dimensions Footprint Width

106 in | 2693 mm

Electrical Number Of Phase

1 | 3

Electrical Voltage At 1 Phase

230 V

Electrical Voltage At 3 Phase

230 V

Kcam Laser Software

KCAM® is a laser cutting and engraving software package developed by Kern's in-house software development team. Through years of research and customer feedback, KCAM® has developed into an industry-leading laser control software.KCAM® can be linked with popular design softwares such as CorelDRAW®, AutoCAD® and Adobe Illustrator®, allowing for hundreds of file types to be processed. A convenient user interface provides operators with complete control of the laser systems cutting and engraving parameters. Kern's customers have access to the latest KCAM® software upgrades from our website.Whether you’re cutting thick acrylic or a thin delicate textile, be ensured that KCAM® will provide you with the laser control required for quick and accurate results.File CompatibilityA macro within CorelDRAW® automatically sends your artwork to KCAM® with the click of a single button. KCAM® is also capable of directly opening common file types such as .dxf, .pdf, G-CODE and many more.Other popular CAD softwares such as AutoCAD LT®, Adobe Illustrator® and Solidworks® can be used to automatically load files into KCAM®.Gives You ControlCustomized Pierce Settings. The dwell time, laser power, frequency, focus point and air flow can be set independently from your normal cut settings. This feature ensures metals are cut clean with minimal to no dross.Air Control. Compressed shop air, oxygen or nitrogen can be hooked up to the laser system for optimal processing results on a variety of laserable materials.Vector Path Speed Control. KCAM® mimics a race car by slowing the cutting speed into sharp corners and accelerating out of them. The result is smooth, consistent cutting with the tap of your mouse.Saves You TimeCut Optimizer. Decrease your programming time by letting KCAM® automatically determine the fastest cut order for your most complicated designs.Time Estimator. Provide accurate pricing to your customers by knowing the amount of laser processing time before the product even makes it to the laser bed.Tool Offset. A simple inside/outside offset can be set to compensate for the laser beam kerf. This results in precisely sized parts without modification of your original part drawings.More KCAM® FeaturesBottom-Up & Top-Down EngravingVector Path Speed ControlSoft Home PositioningPart ArrayingAutomation PausesVision Registration SystemVariable Extents EngravingLead-In Speed ControlLine Color SortingPhotoGRAV CompatibleAnti-Banding Engraving ModeHistory LogNine Vector Cutting ColorsLaser Printer DriverTime EstimatorPower Density Control for CornersMultiple Modulation ModesSystem Usage Log

Materials Cut Material

Acrylic | Aluminum | Anodized Aluminum | Brass | Foam | Leather | Mild Steel | Stainless Steel | Wood

Materials Mark Material

Acrylic | Aluminum | Anodized Aluminum | Foam | Leather | Mild Steel | Stainless Steel | Stone | Wood

Specifications Air Assist Pressure

100 to 250 psi | 9 to 17 bar

Specifications Certification

Underwriters Laboratories (UL)

Specifications Laser Classification

Class 4 Carbon Dioxide (CO2) Laser

Specifications Laser Wattage

100 to 200 W

Specifications Maximum Cutting Speed

20 in/s

Specifications Maximum Engraving Speed

25 in/s

Specifications Optional Packages

Fume Extractor | K-Vision Camera | Metal Cutting | Multi-Zone Table | Pipe Rotary Attachment

Specifications Origin

Made in USA

Specifications Part Clearance

3 in | 76.2 mm

Specifications Positioning Accuracy

0.002 in/ft | 0.1670 mm/m

Specifications Repeatability

0.0005 in/ft | 0.0417 mm/m

Specifications System Weight

6500 lb

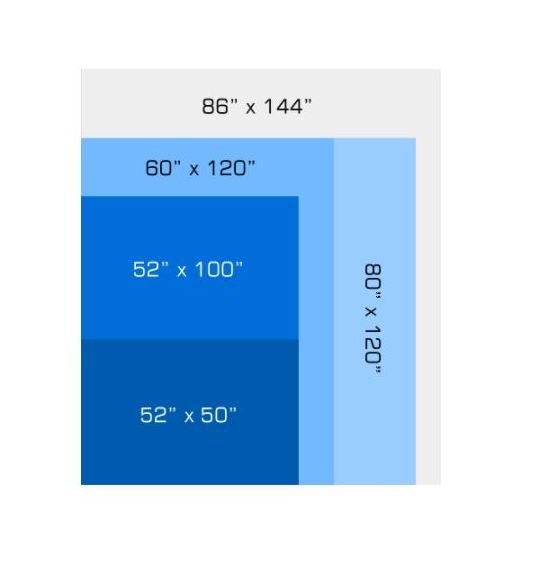

Specifications Work Area

80 x 120 in | 2032 x 3048 mm

Standard Features

Super Pulsed CO2 Laser100-200 Watt CO2 lasers with Super Pulse Technology, developed by Kern Technologies, excel in cutting dense and highly reflective materials.Closed-Loop ChillersTwo closed-loop chilling units properly cool the laser sources, ensuring a long laser lifetime and consistent cutting and engraving results.Vacuum & Fume ExhaustA blower package will remove fumes and small debris created during laser processing. An integrated downdraft table holds material flat on the table.Computer PackageA high-performance computer and monitor is included with each system. An adjustable monitor arm is installed at the front corner of the machine.Software PackageKCAM® Laser Software and CorelDRAW Graphics Suite are linked together allowing over 100 file types to be used, including .DXF, .PDF and G-CODE.Safety FeaturesCDRH laser machinery compliance is ensured with emergency stop buttons, safety labeling, interlocked access points and a 5 second delay safety key switch.Hyperdual MotionKern’s next generation HyperDual motion package features a rack and pinion design driven by powerful servo motors at each side of the table.Training ProgramA 2 day training course at Kern's factory is included with each system. Kern's knowledgeable staff will cover safety, maintenance, operation and applications.