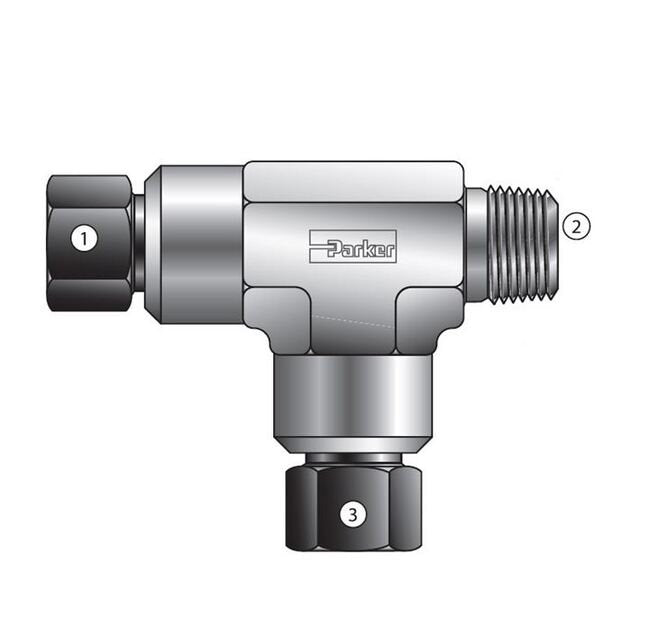

Parker Hannifin RBMP7 MPI to Male Run NPT Tee Fitting

Parker Hannifin RBMP7 MPI to Male Run NPT Tee Fitting

SKU:FIT-d6e02a

Get a secure, leak-free connection with the Parker Hannifin RBMP7 MPI to Male Run NPT Tee Fitting. Designed for medium-pressure applications up to 15,000 psi, this fitting ensures reliability and ease of assembly.

Regular price

$59.99

Regular price

Sale price

$59.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Parker Hannifin RBMP7 MPI to Male Run NPT Tee Fitting is a top-of-the-line compression fitting designed for medium-pressure applications up to 15,000 psi. Featuring a corrosion-resistant Parker Suparcase® front ferrule, a back ferrule for a secure mechanical hold, and an inverted nut coated with molybdenum disulfide, this fitting ensures a leak-free, reliable connection. With materials like Heat Code Traceable 316 SS and optional 2507 Super Duplex, this fitting is ideal for handling liquids, gases, and chemicals. Compliant with ASME Standards, Parker's dedication to quality shines through its reliable engineering and ease of assembly.

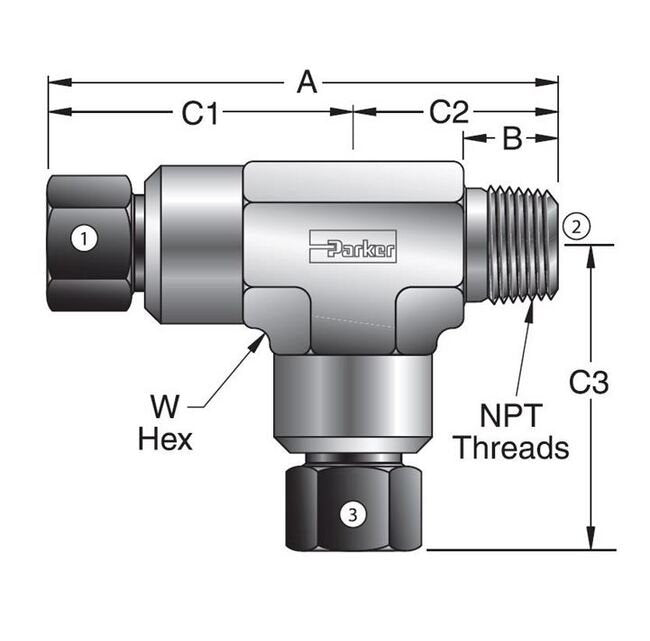

Product Specifications

Dimensions A

2.85 in

Dimensions B

.57 in

Dimensions C1

1.63 in

Dimensions C2

1.22 in

Dimensions C3

1.86 in

Dimensions Connection Type

MPI™ x MNPT x MPI™

Dimensions Mpi Size 1

1/4

Dimensions Mpi Size 3

3/8

Dimensions Npt Thread 2

3/8 - 18

Dimensions Working Mawp Pressure

12000 psig

Dimensions W Hex

7/8 in

Specifications Assembly

MPI™ Fittings are assembled with standard hand tools up to 3/4" size. 1-1/2 turns past finger tight is all that is needed, 3/4 and 1 inch 316 SS tubing and 3/4 and 1 inch 2507 Tubing must be hydraulically preset. Note: All sizes can be hydraulically preset using the Parker Preset Tooling.

Specifications Dedication To Quality

Our resources and vast product line are available through our worldwide distribution network. For more information regarding our products and services, please contact your authorized Parker Instrumentation Distributor.

Specifications Engineering Standards Used

Parker Hannifin has designed all fittings and valves using the following ASME Standards and associated Safety Factors: ASME B31.1 Power Piping ASME B31.3 Process Piping

Specifications Features

Every MPI™ Fitting has the features shown below:Front ferrule with corrosion-resistant Parker Suparcase® forms a seal between the tube, body and ferrule. It also provides a mechanical hold on the tube.Back ferrule with corrosion-resistant Parker Suparcase® provides a strong mechanical hold on the tube.Longer thread area for improved resistance to pressure and load on the ferrules.Molybdenum disulfide-coated inverted nut helps prevent galling, provides easier assembly, and permits multiple remakes.Long tube-support area improves resistance to vibration and line loads.

Specifications Materials And Identification

Standard MPI™ Fittings and Valves are made of Heat Code Traceable 316 SS or optional 2507 Super Duplex materials. Tubing and fitting materials should be selected based on compatibility with the fluid or gas media. Part numbers for MPI™ Fittings use symbols that identify their style, size, and composition. 2507 material is easily identified by a groove in the gland nut hex.