Parker MARSA Soft Seat Relief Valve Set

Parker MARSA Soft Seat Relief Valve Set

SKU:VAL-487312

Reliably vent gases at precise pressures. Soft seat design ensures zero leakage. Ideal for critical pressure gas systems.

Regular price

$199.99

Regular price

Sale price

$199.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

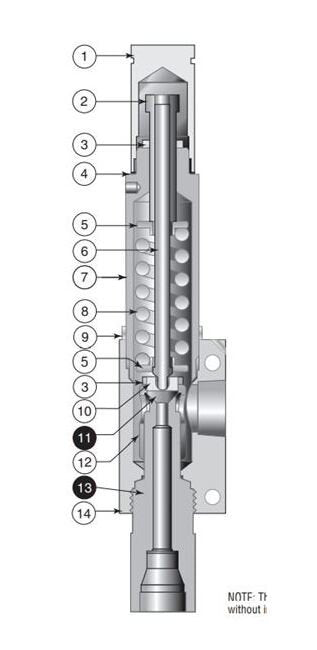

The Parker MARSA Soft Seat Relief Valve (Factory Set) is expertly engineered to reliably vent gases at pressures ranging from 1,500 psi to 15,000 psi. Featuring a soft seat design that ensures bubble-tight sealing and repeatable pop-off and reseat capabilities, this precision valve guarantees zero leakage in pressure gas systems. Designed for critical applications where reliability is paramount, this valve offers a higher cycle life than metal seat relief valves, ensuring long-term performance and durability. Note: Not suitable for liquid nitrogen or liquid carbon dioxide applications. Order your MARSA Soft Seat Relief Valve today for unparalleled reliability and precision.

Product Specifications

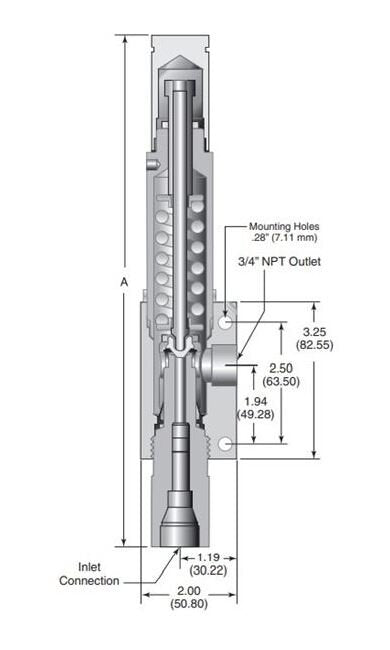

Dimensions A

10.62 in

Dimensions Back Pressure Max

500 psi | 34 bar

Dimensions Connection

MPI™ to FNPT

Dimensions Orifice Diameter

.156 in

Dimensions Pressure Rating Max

10000 psi | 690 bar

Dimensions Pressure Rating Min

5000 psi | 345 bar

Dimensions Repair Kits

R9MARSA-10K

Dimensions Size

9/16 x 3/4

Specifications Caution

Parker Relief Valves are preset and factory sealed. Warranty is voided if seal is broken by customer. Maximum system operating pressure should not exceed 90% of relief valve set pressure. Pressures in excess of this value may cause weepage resulting in damage to plug and seat. Care should be taken when locating a relief valve within a piping system to keep the relief valve as far from the pump as possible. Certain pumps create an end-of-stroke spike in pressure that is not detectable by common instrumentation. These spikes could cause premature failure of the relief valve.