Parker Poly-Mate PM/PXD Depth Filter Cartridges

Parker Poly-Mate PM/PXD Depth Filter Cartridges

SKU:DEP-f438c8

Top-quality Parker Poly-Mate PM/PXD Depth Filter Cartridges for critical food and beverage applications, offering high efficiency and durability.

Regular price

$39.99

Regular price

Sale price

$39.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Parker Poly-Mate PM/PXD Cartridges offer top-quality and cost-effective filtration solutions for critical food and beverage applications. With a unique polypropylene meltblown and spunbonded media, these cartridges provide a high surface area, finish-free filtration that does not release fibers. Designed for durability, all-polypropylene construction ensures maximum chemical resistance to acids, bases, salts, and organic solvents. The PM cartridges are rated for 99% efficiency, boasting a high pleated surface area for extended service life, low pressure drop, and high flow capacity. For added strength, the optional stainless steel O-ring adapter inserts allow for in situ sterilization, meeting FDA standards for potable and edible liquid contact.

Product Specifications

Applications 0

Food & BeverageDeionized waterR.O. membrane prefiltrationProcess water

Benefits 0

High efficiency rated for critical food and beverage applications (99% efficiency)High pleated surface area for extended service life, low pressure drop and high flow capacityOptional stainless steel O-ring adapter inserts provide added strength for in situ sterilization. Poly-Mate⢠Xtra Duty cartridges are available with backwashable construction, reducing replacement maintenance and cartridge disposal costsPoly-Mate⢠Xtra Duty (PXD) cartridge features glass-filled polypropylene core for high temperature and high pressure use with rigid outer cage supporting pleated media in backwash applicationsAll materials of construction are FDA listed as acceptable for potable and edible liquid contact according to CFR Title 21.One-piece, continuous to 40 in length, integrally sealed, pleated filter media

MATERIALS OF CONSTRUCTION CAGE Material

Polypropylene Netting

Materials Of Construction Filter Media Material

Polypropylene

Materials Of Construction Support Core Material

Polypropylene

Materials Of Construction Support Layers

Polypropylene

Note 0

Specifications are subject to change without notification.Poly-Mate⢠is a trademark of Parker Hannifin Corporation.Viton® is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

Recommended Operating Conditions Changeout P

35 psid | 2.4 bar

Recommended Operating Conditions Maximum P 200f 93c

10 psid | 0.7 bar

Recommended Operating Conditions Maximum P 70f 21c

60 psid | 4.1 bar

Recommended Operating Conditions Maximum Temperature

200 ºF | 93 ºC

Specifications Cartridge Code

Standard

Specifications Effective Filtration Area Per 10 Inch 254 Mm

0 to 6.0 ft² | 0.6 m²

Specifications End Cap Configuration

020 O-Ring/Recessed Cap | 120 O-Ring/Recessed Cap | 213 O-Ring/Recessed Cap | 222 O-Ring/Fin | 222 O-Ring/Flat Cap | 226 O-Ring/Fin | 226 O-Ring/Flat Cap | DOE with Core Extender | Double Open End (DOE) | Ext. Core Open End/ Polypro Spring Closed End | S.S. Inserted 222 O-Ring/Closed | S.S. Inserted 226 O-Ring/Closed | S.S. Inserted 226 O-Ring/Fin | Std. Open End/ Polypro Spring Closed End

Specifications Filtration Ratings

99 %

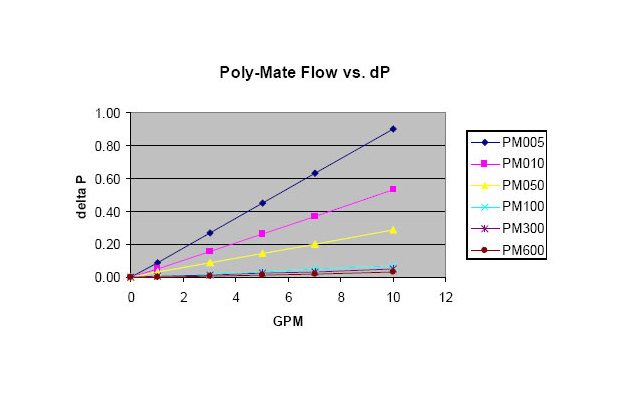

Specifications Flow Factors Psidgpm 1 Cks Per 10 Cartridge

0.0900

Specifications Maximum Recommended Flow Rate Per 10 Length 254 M

10 gpm | 9.5 lpm

Specifications Nominal Length

30 1/16 in | 764 mm

Specifications Particle Removal Rating

0.5 µm

Specifications Seal Material

Buna-N | EPR | No Seal Material | PFA Encapsulated Viton® (O-Ring only) | Polyethylene Foam (DOE Gasket only) | Silicone | Viton®

Specifications Special Options

Bubble-Point Test | DI Water Rinse (5 minutes) | Individual Poly Bag only

Specifications Support Construction

Natural Polypropylene

Technical Support And Product Information 0

Parker provides our customers with unsurpassed product consistency and cost efficiency. Our experienced professionals can help you select the right solution for your application. Orders can be emailed directly to PAFsales@parker.com. For additional information contact your local distributor. Information on product specifications, applications and chemical compatibility can be found on our web site at www.parker.com or through the Oxnard office.Parker designs and manufactures an extensive line of innovative solutions for specific applications in the Microelectronics, Biopharmaceutical, Food and Beverage, Coatings and Inks, Process and Chemical industries.