Pennsylvania Steel Co. H13 DCF Grade 2-1/2 Inch Tool Steel Round Rod

Pennsylvania Steel Co. H13 DCF Grade 2-1/2 Inch Tool Steel Round Rod

SKU:IND-6c631d

Premium H13 DCF Grade 2-1/2 in Tool Steel Round Rod for high-strength industrial applications. Superior heat resistance and durability.

Regular price

$45.99

Regular price

Sale price

$45.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Pennsylvania Steel Co. H13 DCF Grade 2-1/2 Inch Tool Steel Round Rod is expertly crafted for industrial applications that demand high strength and durability. Made from premium H13 DCF grade steel, this round rod offers superior heat resistance and toughness, ensuring long-lasting performance under extreme conditions. With a weight of 17.026 lb per foot, it provides the stability and reliability required for heavy-duty machining tasks. Ideal for tool making, die casting, and metalworking, this tool steel round rod from Pennsylvania Steel Co. is a top choice for professionals seeking quality and precision.

Product Specifications

Accessories And Options 0

Corrosion resistant tank lining. Auto tank drains. Desiccant air treatment systems. Refrigerated air treatment systems. Remote inlet filters. Master lead/lag controllers for multiple cabinets. NFPA 99 compliant systems. Laboratory system packaging. Air quality monitors (CO, dew point). Special motors (premium efficient, 50 Hz).

Additional Information 0

Powerex® introduced the first dry scroll to the US oil-less compressor market in 1989.The enclosed scroll compressors feature compact footprints, energy efficient operation, low maintenance, and environmentally friendly design, all in one complete package.Redundancy is built into our system with our multiple pump design, eliminating the need to purchase an additional compressor.Why Powerex®?Powerex® has been designing and packaging systems since 1988 and has built a foundation on engineering, innovation, quality and service to become a leader in both air and vacuum systems. Because of our high level of vertical integration and a full in-house engineering team, Powerex® has the ability to customize a system to meet your air or vacuum requirements.

Advanced Controls 0

The system display shows current operating conditions, pump run status, system pressure, run hours, and alarms. The onboard diagnostic system constantly monitors the system and alerts the user of any problems or service required. Advanced control logic determines when to stage compressors to yield maximum energy efficiency.

Compression Principle 0

As the orbiting scroll orbits from No.1 to No.4 position, a crescent-shaped cavity is gradually reduced, compressing the air and exhausting it through the final discharge point at the center.

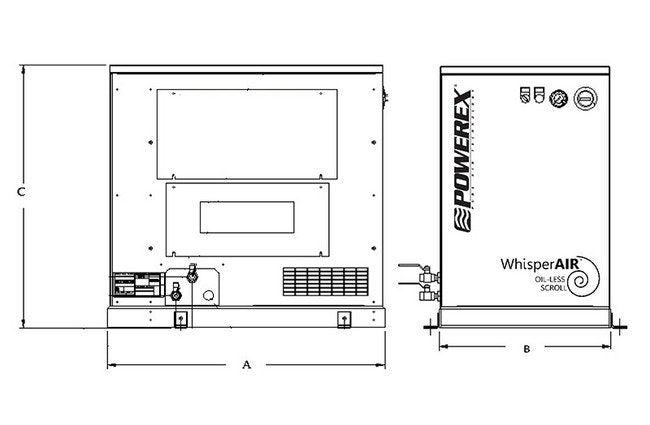

Dimensions Height

33 in

Dimensions Length

34 in

Dimensions Width

21 in

Eliminate Waste 0

With no oil in the compressor you can rest assured that you are doing your part for the environment.

Energy Efficiency 0

With the Powerex® Variable-Pump-Drive system, each compressor pump is automatically staged on/off individually based on actual system demand, maximizing energy efficiency at all usage levels. Lead compressor status will alternate every time a pump is called for â or every 10 minutes, whichever comes first - which maintains equal run hours and extends maintenance intervals.

Features 0

Integral 13 gallon tank ASME/CRN. Inlet filtration with replaceable element. Front mounted control panel includes: On/Off switch. Power on light. High temperature shutdown with indication light. Run time hour meter. Pressure gauge. Automatic start/stop operation. Control voltage starter with motor overload protection. Internal vibration isolators. Air-cooled aftercooler.

Financing Approve Payments

Finance with Approve Payments

Note 0

Single phase models use motors that require input voltage of 230 V.Single phase 3 hp units require the installation of an additional 30 gal external tank.For more information, contact your localPowerex® distributor or Powerex® sales representative today!

Redundancy 0

It's built right in with our multiple pump design, eliminating the need to purchase an additional compressor.

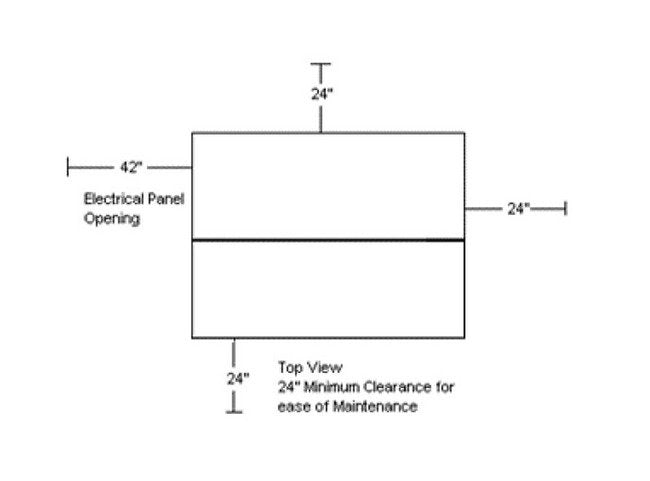

Sound Enclosure Cabinet 0

Each system is packaged in a rigid steel frame with powder coated panels and lined with sound-deadening insulation. The low noise levels are unmatched in the industry and allow installation at the point of use, while the small footprint simultaneously maximizes floor space.

Specifications Air Receivers Capacity

30 to 60 gal

Specifications Compressor Capacity

12,725 Btu/hr

Specifications Dimension A

34 in

Specifications Dimension B

21 in

Specifications Dimension C

33 in

Specifications Discharge

3/8 in

Specifications Industry Standardscertifications

UL/CSA Certified

Specifications Integral Receiver

13 gal

Specifications Maximum Pressure

145 psig

Specifications Model Type

Simplex

Specifications Motor Type

Open Drip Proof (ODP)

Specifications Noise Level

51 dBA

Specifications Operating Pressure

115 to 145 psig

Specifications Performance Air Flow At 100 Psig

12.5 scfm

Specifications Pump Power

5 hp

Specifications System Full Load Current Fla At 208 V

14.5 A

Specifications System Full Load Current Fla At 230 V

13.1 A

Specifications System Full Load Current Fla At 460 V

6.6 A

Specifications System Weight

335 lb

Specifications Weight

355 lb

Technology And Innovation 0

The scroll pump has few moving parts making it reliable and easier to maintain. The self-lubricating tip seals, and absence of a gearbox means the pump is truly 100% oil free.As the leaders in scroll pump technology, our latest design incorporates several innovative features: Main bearings are housed in durable cast iron instead of aluminum which prevents fretting and premature failure of the bearing race. This pump can be operated at 100% duty with confidence. The patented bearing re-grease feature has been improved to allow maintenance from the front side of the pump, cutting service time in half. The patented tip seal design yields the highest flow rates and longevity of any other dry scroll compressor. The improved efficiency and cooling results in lower operating temperatures. Extremely low vibration. Industry first 10 hp scroll pump improves system efficiency by producing more output using fewer pumps.

The Powerex Oilless Advantage Benefits Of An Oilless Compressor

Extremely reliable. 100% oil free system. No contamination of product. No contamination of powered equipment. More environmentally friendly. Less filtration required. Less maintenance â no oil changes needed! No oil water separators needed.

The Powerex Oilless Advantage Disadvantages Of An Oil Flooded Co

Potential oil contamination of product. Potential oil contamination of powered equipment. Low-quality âoil freeâ compressors can damage equipment. Potential oil contamination of environment. Require additional activated carbon filters. Higher level of maintenance â oil changes and filter maintenance required.

Total System Approach 0

We know how critical the air purity is for your application and can provide a complete solution. From individual components to complete turnkey packaged systems with air receivers, desiccant or refrigerated air dryers, filtration down to .01 micron, air quality monitoring and more.The graph shows the relationship of daily air consumption of the plant and the corresponding electrical consumption of the compressor. When air consumption fluctuates the variable pump drive control logic is much more efficient.