PerMix PDR 200L Drum Hoop Mixer

PerMix PDR 200L Drum Hoop Mixer

SKU:PDR-8eb5b1

Efficient 200L Drum Hoop Mixer for quick and intensive mixing in chemical, food, nutraceutical, and pharmaceutical industries.

Regular price

$7,999.99

Regular price

Sale price

$7,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

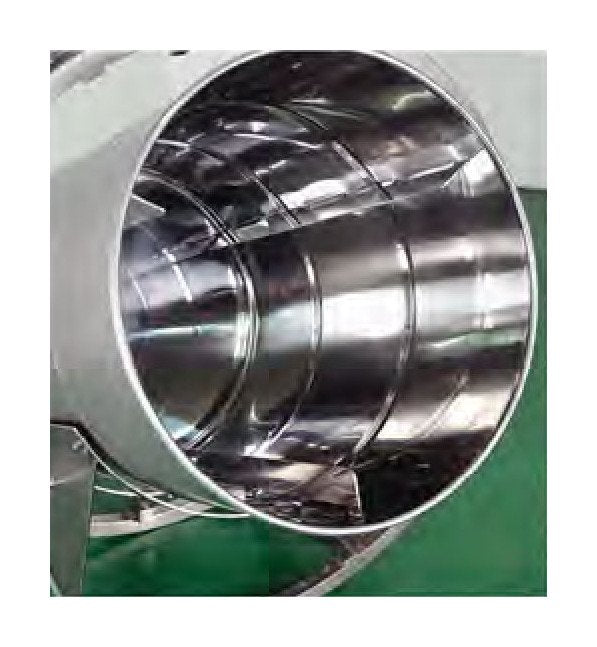

The PerMix PDR 200L Drum Hoop Mixer is a versatile solution designed for industries requiring efficient mixing, blending, and homogenizing of dry powders and granules. With a total volume of 200 liters and a robust construction, this mixer offers a maximum loading weight of 120 kg and operates at a power of 1.1 kW. Its innovative design ensures intensive mixing within 10 to 12 minutes, making it ideal for applications in the chemical, food, nutraceutical, and pharmaceutical industries. The PerMix PDR series excels in facilitating quick product changes and eliminates the need for additional hoisting equipment, ensuring ease of use and maintenance.

Product Specifications

Additional Information Additional Information

PerMix Drum Hoop Mixers comprise a drive unit with roll-on/roll-off ramp, and it is used in mixing, homogenizing and dyeing of powdery or granulated components in the plastics industry, chemical industry, drug and dye works, food industry as well as textile and leather industry.Drum capacity of PDR Mixer is usually 200L, but also available with 50 and 100 liters. Usually the drum is available as standard product in the market; however customized drums are also accepted, and the hoop then needs to be adapted to the drum size.

Advantages Advantages

Drum Mixers as well suitable for frequent product changes, as the storage container at the same time serves as a mixing container.Drum Mixers avoid inappropriate handling of dusty or tonic products.Hoop can be used for transporting drum.Easy exchanging of the mixing container.No need for drum hoists, cradles, etc.Easy cleaning of the mixing container.Optional internal paddle baffles mounted in the drum.

Applications Applications

PerMix PDR series Drum Hoop Mixers are used widely in many applications, including but not only:Food & Drinks : Breakfast Cereals, Enzymes, Flavours, Herbs, Minerals, Nutraceuticals, Seasonings, Spices, Tea Mixes, Tobacco, Vitamin MixesChemicals : Agrochemicals, Ceramic Powders, Deter gents, Drugs, Dyestuffs, Leather Auxiliaries, Metal Powders, Pigments, Plastic Granules, Plastic Pellets, Plastic Powders, Textile AssistantsPharmaceuticals: Active Agents, Biological Solids, Carcinogenic Substances, Concentrated Active Ingredients, Generics, Intermediate Products, Sterile Products, Toxic Substances

Features And Options Features And Options

Features of a PerMix PDR series Drum Mixer compared to a conventional mixer are:Intensive mixing with optional internal paddle baffles mounted in the drum.Well suitable for frequent product changes, as the storage container at the same time serves as a mixing container.Avoids inappropriate handling of dusty or tonic products.Hoop can be used for transporting drum.Easy exchanging of the mixing container.No need for drum hoists, cradles, etc.Easy cleaning of the mixing container.Optional GMP execution.

How It Works How It Works

PerMix Drum Hoop Mixers consist of a motor / worm gearbox, and two shafts with 4 rollers located on the machine base with a ramp. A hoop is designed to hold the mixing drum which is fed with powdery or granulated materials. The mixing drum can be a standard drum with full volume varying from 50L to 200L, or a drum in customized shape/volume. The hoop will be adapted to hold the drum tightly by a belt with two hooks.To perform the mixing duty, the hoop and drum assembly is rolled manually up along the ramp until finally located on the four rollers. The drive unit moves the shaft that is connected to it, and the two rollers on the shaft move the hoop / drum, and then the other shaft / 2 rollers will rotate.The mixing drum is lying inside the hoop with an angle, thus the material inside will move not simply up and down but also left and right, which leads to a homogeneous mixing after several minutes.

Note Note

All specifications are as accurate as is reasonably possible, but they are not binding.Length, width, height, weight are without the drum.Customized sizes are available against request.PerMix reserves the right to modify the design without notice.

Specifications Height

1190 mm

Specifications Intensifier Bar

Not Available

Specifications Length

1600 mm

Specifications Maximum Loading Weight

120 kg

Specifications Mixing Time

10 to 12 min

Specifications Mixing Volume

50 %

Specifications Most Used Industry

Chemial | Food | Nutraceutical | Pharmaceutical

Specifications Operation Volume

100 L

Specifications Percent Of Product Residue

<1 %

Specifications Power

1.1 kW

Specifications Size Footprint

Low (0.90 m²)

Specifications Speed Of Drum Hoop

20 rpm

Specifications Total Volume

200 L

Specifications Weight

270 kg

Specifications Width

670 mm