PerMix PFBS 8000L Fluidized Zone Mixer

PerMix PFBS 8000L Fluidized Zone Mixer

SKU:PFB-52cb2d

Achieve precise and fast mixing with the PerMix PFBS 8000L Fluidized Zone Mixer, perfect for diverse industries.

Regular price

$34,999.00

Regular price

Sale price

$34,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The PerMix PFBS 8000L Fluidized Zone Mixer is a high-efficiency mixing solution designed for fast and precise blending of various materials, regardless of particle size, shape, or density. With a total capacity of 8000 liters and a power of 45 kW, this mixer offers very fast mixing times, minimal heat generation, and low shear, making it ideal for shear and heat-sensitive products. Its unique design creates a weightless mixing zone, ensuring homogeneous results while preserving the integrity of delicate materials. Additionally, features like easy cleaning, multiple drive system options, and optional chopper attachments enhance its versatility and performance across industries such as chemicals, construction, food, and pharmaceuticals.

Product Specifications

Additional Information Additional Information

Due to its high efficiency and reliable performance, PerMix Single-Shaft Fluidized Paddle Mixers are widely applied in many industries, including but not limited to: Building materials, Fly ash conditioning, Animal feeds, Mineral premixes, Instant drinks, Milk powders, Vitamin mixes, etc.

Applications Building Industry

Blended Cements | Brick Facings | Cement and Fibers | Dry Mortar | Flooring Materials | Joint Compounds | Road Lining Materials | Tile Adhesives/Grouting

Applications Chemical Industry

Boric Acid | Carbon | Color Pigments | Detergents | Explosives | Fertilizers | Fly Ash | Fungicides | Soda Ash

Applications Environmental Applications

Filter Dust Treatment | Fly Ash Conditioning | Food Waste | Sewage Sludge

Applications Feed Industry

Animal Feed | Aqua/Fish Feed | Dairy Additives | Mineral Premixes | Pet Food

Applications Food Industry

Flour/Bread/Bakery Mixes | Frozen Vegetables | Infant Milk Powder | Instant Drinks/Soups | Treatment of Spices

Applications Other Applications

Bio | Health and Beauty | Nutraceutical

Applications Pharmaceutical Industry

Medical Mixes | Vitamin Mixes

Features And Advantages Features And Advantages

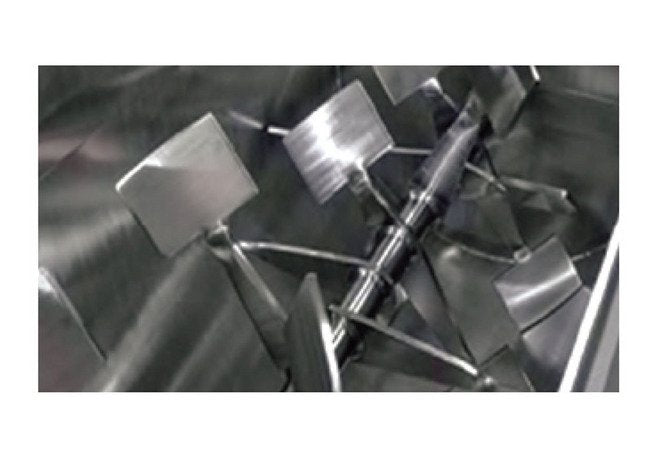

Compared with other powder mixers, PerMix PFBS series Single-Shaft Fluidized Paddle Mixers are featured in:Very fast mixing to supply a typical mixing time from 10 seconds to only 1.5 minutesFree particle movementMinimal heat and low shear for shear and heat sensitive materials (Due to the fact that low friction without shear in this non-gravity zone is generated, this makes the PerMix PFBS series Fluidized Paddle Mixers an ideal machine for fragile products that can't tolerate rough handling, even flakes or spray dried bodies remaining intact after mixing.)Easy cleaning and hygienic design with minimal blind cornersLow maintenanceBig bomb bay door for fast discharging & reduced segregation are optionalLiquid addition by spray balls, nozzles, or dripping pipesLeading edges of the paddles can be coated by Tungsten Carbide for very abrasive materials.Intensive choppers to break lumpsVarious drive system (single motor/gearbox with chain; dual motor/gearbox, single motor with dual gearbox)

How It Works How It Works

The PerMix PFBS Fluidized Paddle Mixer consists of paddles with special angles that are mounted on a single shaft in a "U" shaped trough.The paddles sweep the entire bottom of the trough, and materials are lifted floating in the trough (as zero-gravity zone) by the centrifugal force generated by the paddles.At this weightless zone, mixing of materials of different density is easy and fast because material particle can move freely and randomly, regardless of particle size and density. This brings a rapid and highly homogeneous mixing.PerMix Fluidized Paddle Mixers can be with either single shaft or dual shaft with overlapping paddles (single drive with chain transmission), or tangential paddles (twin motor/gearbox drives), this is our PFB series.

Note Note

All specifications and illustrations are as accurate as is reasonably possible, but they are not binding.PerMix reserves the right to modify the design without notice.

Overhead Chopper Overhead Chopper

Although the PerMix PFB series Single or Twin-shaft Paddle Mixer is featured by its gentle mixing at the weightless zone, it can also achieve rough mixings with additional PerMix Pin Milling Bars to be installed on the top of the paddles.The PerMix Pin Milling Bars are two rapidly rotating bars with pins and a stationary shroud, which introduce high shear force onto the materials during mixing to break soft lumps and agglomerates. In this case, a fill level of 140% of normal capacity is required.PerMix offers pneumatic discharge valves for the PFBS Fluidized Paddle Mixer for quick discharging when the paddles are running, eliminating any possible segregation. Each valve is located at the bottom of the basin of the U-shaped trough.PerMix also supplies the large Bomb Bay Door for even faster and complete discharging with the bomb bay doors, the discharging time can reduce to less than one minute (product and mixer size dependent).

Specifications Height

2504 mm

Specifications Length

4590 mm

Specifications Outlet Size

700 x 120 mm

Specifications Power

45 kW

Specifications Speed

24 rpm

Specifications Total Capacity

8000 L

Specifications Useful Capacity

3200 to 4800 L

Specifications Weight

6800 kg

Specifications Width

1956 mm