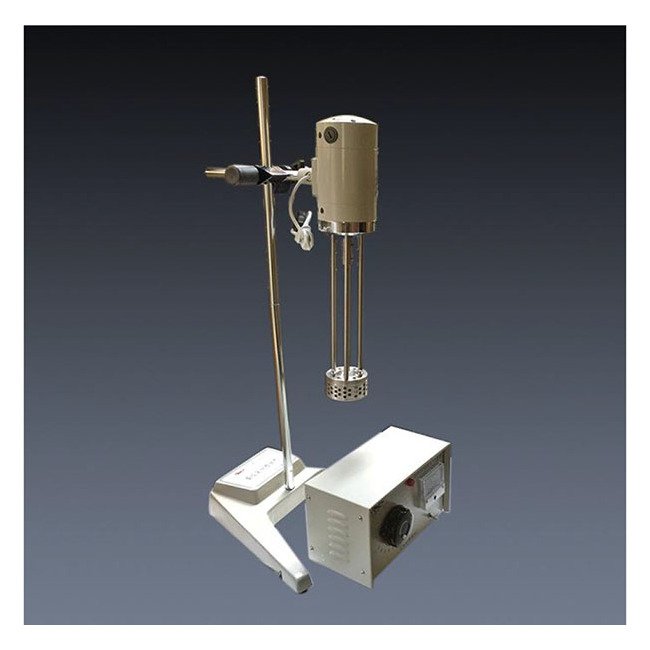

PerMix PS 12000L High Shear Mixer

PerMix PS 12000L High Shear Mixer

SKU:PSH-96db6d

Efficiently disperse solids into liquids with the PerMix PS 12000L High Shear Mixer. Ideal for food, pharma, and cosmetics.

Regular price

$28,999.00

Regular price

Sale price

$28,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Achieve precise emulsions, disperse solids into liquids efficiently with the PerMix PS 12000L High Shear Mixer. With a 75kW power, 1500 rpm speed, and innovative stator/rotor system, this mixer ensures deagglomeration, homogenization, and dispersion for various industries like food, pharmaceuticals, and cosmetics. Choose from V and K Stator & Rotor designs for tailored mixing solutions. The high shear mixer complies with federal/DoD procurement standards, FAR compliance, and industry-specific certifications, ensuring quality and performance for institutional buyers.

Product Specifications

Additional Information Additional Information

Unlike conventional mixing, PS Mixer is structured with an innovative stator-rotor. This special design makes PS Mixer not only simply mix, but also disperse, suspend, emulsify, homogenize and disintegrate liquid and solid. PerMix PS Mixers are used to handle a wide range of products in the food-processing, cosmetics, pharmaceutical and fine chemistry industries.

Applications Applications

High Shear Mixers are widely used by a variety of industries in different stages of the processing. They are highly efficient to save a lot of energy and time compared with traditional mixing methods.Food & BeverageReconstituted milk, Salad dressing, Mayonnaise, Ice cream, Cheese, Yogurt, Fruit juice Pharmaceutics & BiologyDrug synthesis, Vaccine, Fat emulsion, Injectable suspension, Veterinary medicine, Cell extractionCosmetics & Daily CareDetergent, Body gel, Shampoo, Cream, Lotion, Tooth paste, Soap

Installation And Set Up Installation And Set Up

In the Batch process, the mixer is immersed into the liquid. There are many installation methods for the batch mixer. It can be lifted up by a lifting stand (hydraulic or electric), or it can be installed with flange on the top of a tank, or from its side, or at its bottom. For the vacuum or pressurized tank, the mixer must be equipped with a mechanical shaft sealing.Top entry, open vesselThese mixers are used in an open vessel, that is, a vessel with normal pressure. They are top entry mixers, can be installed onto a lifting stand, or directly onto the vessel by a flange or traverse. A coupling between the motor and shaft is optional for low noise and stable running.Top entry, closed vesselThese top entry high shear mixers are with a mechanical seal, which enables them to be working in a pressurized or vacuum vessel. Single seal or double seals are available. Side entryThe side entry mixers are very useful when the tank is deep but narrow, or when the top space of the vessel is limited for the top entry ones.Bottom entryThe bottom mixers are outstanding when the liquid level in the tank can get very low during operation, or there is very limited space above or around the tank for either top or side mounted ones. What is more, strong vortex as well as aeration is greatly reduced with the PERMIX bottom mounted mixers.

Note Note

PS-C, PS-D, PS-M share the same specifications.Actual liquid capacity will vary depending on the liquid type and different stator rotor system.PerMix offers bigger capacity according to customer requests.PerMix reserves the right to modify the design without notice.

Specifications Maximum Capacity At 3000 Cycles Per Second Cps Sp

6000 L

Specifications Power

75 kW

Specifications Shaft Length

1550 mm

Specifications Speed Of Mixing Can

1500 rpm

Specifications Total Volume

12000 L

Statorrotor System Statorrotor System

We offer two types of Stator & Rotor systems: V and K, and both have several sub-types. The reason to have so many designs of stator & rotor systems is to offer more selections for our customers to choose the most suitable one to deal with their specific liquids and solids.

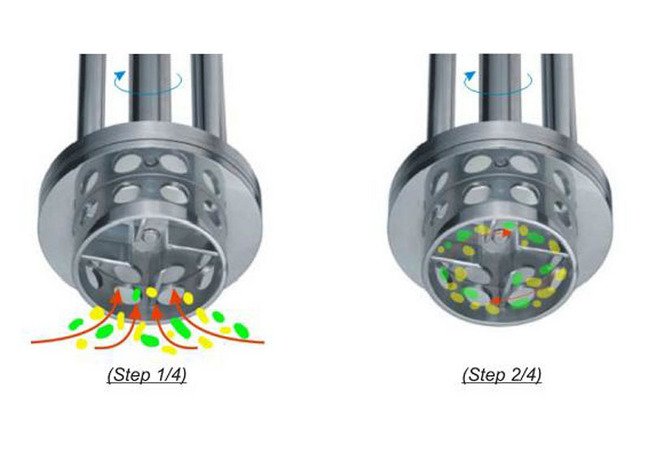

Working Principles Working Principles

High Shear Mixers work with a special designed stator/rotor working head. When it works, this stator/rotor head is able to draw the solids and liquids around it into its center, and then push them radially through the stator openings back to the tank.During this period, the solids and liquids are subject to an action of milling and shearing which is so intensive that they are deagglomerated, homogenized and dispersed into each other even though they are immiscible by traditional agitation.There are four steps to explain the working principle:Step 1. When the rotor is driven by the motor, it rotates at a very high speed of several thousands rpm. A powerful suction is generated at its center and draws both solids and liquids from the bottom of the tank into the central zone.Step 2. Centrifugal force leads the materials to the periphery. Materials are subjected to intensive squeezing and milling at the precision machined clearance between rotor and stator. High pressure is created there too due to the gathering of materials, which makes the impact between particles more remarkable.Step 3. Followed is another intense hydraulic shear as the materials are forced out through the openings in the stator at very high velocity. When material particles arrive outside of the stator, they tend to explode into thousands of even smaller ones as the pressure drops down sharply.Step 4. Fresh materials are continually drawn into the stator-rotor maintaining the mixing cycle. Due to the vortex in the tank, materials in every corner of the tank can pass through the stator-rotor system again and again, resulting in fine droplet size.