PerMix PT-C/Y 30 kW Powder Liquid Mixer

PerMix PT-C/Y 30 kW Powder Liquid Mixer

SKU:PTC-b422cd

Experience efficient powder-to-liquid mixing with the PerMix PT-C/Y 30 kW Mixer.

Regular price

$8,999.99

Regular price

Sale price

$8,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

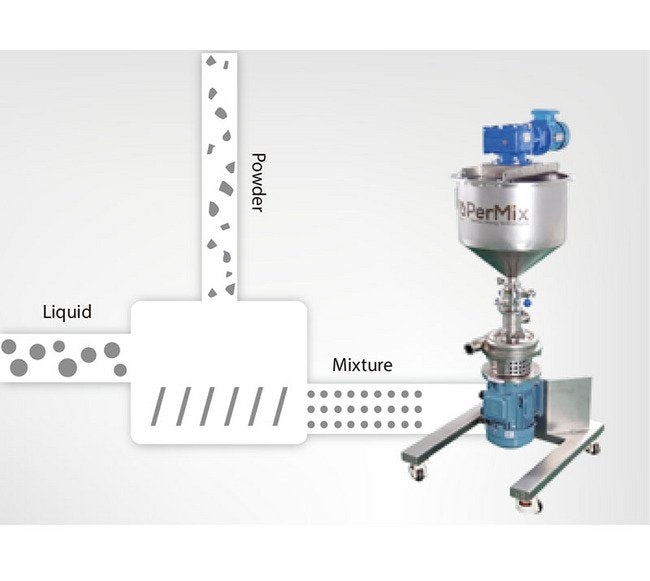

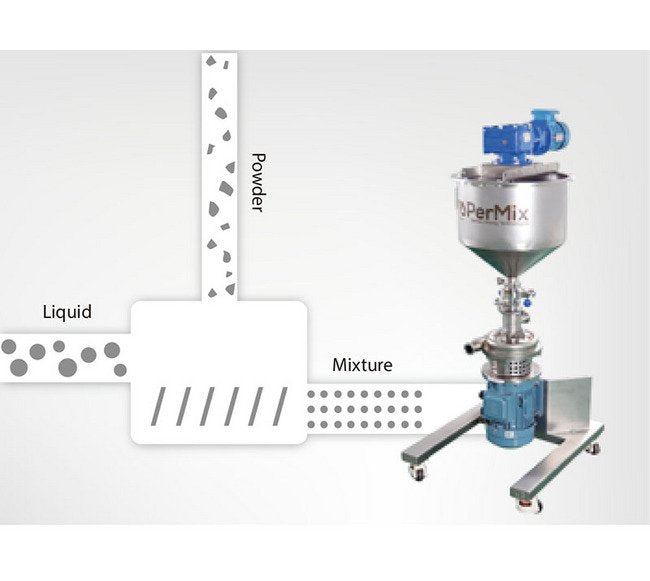

The PerMix PT-C/Y 30 kW Powder Liquid Mixer is a specialized equipment designed for efficient powder-to-liquid mixing. Featuring a specially designed stator/rotor system that produces high vacuum, this mixer enables easy powder induction at high rates. With applications ranging from preparing syrups to suspending pigments, this mixer offers versatility and precision in various industries.

Product Specifications

Additional Information Additional Information

PerMix offers four (4) types of Powder Liquid Mixer, covering the common product range in the market:PT-C/Q (Double Wall Design)PT-C/Y (Special Stator Rotor)PT-C/F (Two Pumps Design)PCH (Shear Pump)With its many distinguished features and options, PerMix PT-C Powder Liquid Mixers are widely used in mixing of almost all kinds of powdery products by a variety of industries, e.g. food and beverage, dairy care, pharmaceutical, chemical.

Applications Applications

Some typical applications can be:Preparation of syrup, sorbitol, glucose, lactose, etc.Reconstitution of powdered milk, whey, protein, etc.Dissolution of CMC, Xanthan gum, etc.Preparation of flour and starch slurriesPreparation of brinesPre-mixtures of yogurt and other milk-based dessertsSuspension of bentonites, TiO2 in pigmentPreparation of pesticides and fertilizers

How It Works How It Works

The four types of powder liquid mixer share similar working principle, but with some difference:PT-C/Q (Double Wall Design)The PerMix PT-C/Q powder liquid mixer is the most common type which is also called Tri-blender. It has two key parts, a casing pipe and a stator rotor system.The casing pipe is built vertically and coaxially into the stator rotor system inlet. This double-wall design prevents the powder going through the casing pipe contacting the liquid and forming lumps before they both arrive at the stator rotor system.As the rotor running at high speed during operation, liquid enters into the chamber and a water ring is created. Vacuum is generated at the center which causes suction of the powder from the hopper above the chamber. A valve at the bottom of the hopper is used to regulate the falling rate of the powder. As soon as the powder gets in contact with the liquid, it is wetted and dispersed into the liquid by the turbulence and later high shear force when the mixture goes through the precise machined clearance between the stator and rotor, and radiated out through the stator openings.By choosing different types of stator rotor, it can provide various functions of powder wetting, homogenizing, etc PerMix provides high shear stator/rotor, low shear stator/rotor; and in some cases where the powder is easily being dissolved into the liquid, only a regular centrifuge pump impeller is used without a stator, and it provides higher volume flowrate and bigger powder induction rate.PT-C/Y (Special Stator Rotor)PerMix PT-C/Y series Powder Liquid Mixer has a very specially designed stator/rotor, which works by the principle of a water ring pump, that is able to produce relatively high vacuum; this vacuum makes the PT-C7Y mixer able to suck the powder through a hand-held wand from a bag or other container at ground level. The powder can also be incorporated from a vertical hopper by gravity at a much higher powder sucking rate.PT-C/F (Two Pumps Design)The PT-C/F Powder Liquid Mixing System is designed with the combination of a self-priming pump and an inline homogenizing mixer. The self-priming pump draws the liquid from an external container, and when the liquid passes through a venturi pipe which is located at the bottom of a powder hopper, vacuum is generated there and sucks the powder from above. The powder/liquid mixture will first pass through the self-priming pump, and later get further sheared and dispersed at the inline homogenizing mixer.PCH (Shear Pump)By adding a hopper at the inlet of the liquid, our PCH shear pump can be converted to a powder liquid mixer, to provide perfectly good sucking performance for dry and free flowing powders, for example, milk powder, dry flour, etc. Due to the relatively simple and compact design and full stainless steel construction, the PCH is popular in many hygienic applications.

Note Note

Actual liquid and powder capacity will vary depending on the material characters and stator rotor type.PerMix offers special models according to customer requests.PerMix reserves the right to modify the design without notice.

Options Options

A lot of options are available for the PT-C Powder Liquid Mixer:Powder hand-held hose assemblyVariable speed motor; Frequency converterMulti-row, multi-stage stator & rotorMetal part to be SS316L or othersGasket sealing of FPM, FFPM, etc.Hopper of 50°, 60°, etc.Hopper vibrator or Air sweeperSingle or double mechanical seals

Specifications Maximum Liquid Capacity

20 t/h

Specifications Maximum Powder Capacity

0 to 5 kg/min

Specifications Power

15 to 30 kW

Specifications Speed Of Mixing Can

3000 rpm