Phoenix PCTA-2100 Automatic Rotary Turntable with Touchscreen Controls

Phoenix PCTA-2100 Automatic Rotary Turntable with Touchscreen Controls

SKU:MAC-3488e5

Boost efficiency with Phoenix PCTA-2100 Turntable - Touchscreen Controls, Pre-Stretch Carriage, Pneumatic Cut & Wipe

Regular price

$7,499.99

Regular price

Sale price

$7,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

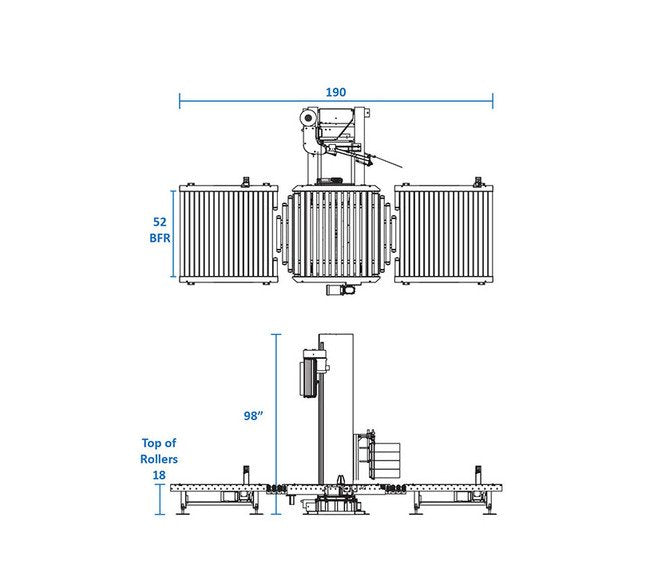

Enhance your pallet wrapping efficiency with the Phoenix PCTA-2100 Automatic Rotary Turntable. This durable and dependable stretch wrapper features a precision ground bearing support, pre-stretch carriage for film savings, and a pneumatic cut & wipe system for secure wrapping. With up to 35 pallets/hour production speed and user-friendly touchscreen controls, this turntable ensures fast and efficient operations tailored to your exact requirements.

Product Specifications

Control Motor Controls

Variable Frequency Drives

Control Top And Bottom Wrap Counters

Separate 1 to 9 Count

Control Updown Speeds Carriage

Separate

Features Features

Touchscreen ControlsThe PCTA-2100 and PCTA-2003 comes complete with an Allen Bradley PLC & Operator Touch Screen.Including: NEMA 12 Control Enclosure 24 V Control System.Separate Carriage Up/Down Speed Control.Auto height Photo-Eye for Variable Load Height detection.Film Force to Load (Tension) Control.Ring Bearing DrivenThis precision ground bearing support is the same principal that is used for army tanks, cranes, and foundry equipment. Where large oversized structures need to be supported in extreme harsh environments.Although the use of such a bearing in a light application like a stretch wrapper is extreme over-engineering, it provides a clean bullet proof solution to the weight support and rotation of our table.Pre-Stretch CarriageA solid design concept both mechanically and electrically for a durable, dependable powered Pre-stretch film carriage with added operator safety in mind!The Phoenix film carriage design allows for the fastest and safest roll change in the industry.Simply open carriage gate, lay the film on the gate, and close the gate. IT'S THAT SIMPLE !Cut & Wipe SystemThe pneumatic controlled cut & wipe system automatically cuts the film and applies the film tail to the load. A timed impulse heat system, cold to the touch in seconds offers a safe cutting system.Pneumatic driven clamp holds the film tail during rotation. The clamp release the film tail at the end of the cycle and once the table stops, the film clamp is activated to close and hold the film for the cutting process.Nothing Beats the Best in Class!Fast: Up to 15 RPM stretch wrapping speed. Fastest in its Class.Reduced Film Usage: Simple yet powerful controls provides flexibility and film savings. Separate 1-9 top and bottom wrap count provides up to 15% Savings.Superior Standard Features: Best in Class Wrapping Flexibility with Touchscreen Control provides all features as standardâ¦. Including those not available (or an upcharge) on competitive models.

Note Note

Specifications subject to change without notice.

Performance Maximum Diagonal Load Size

71 in

Performance Maximum Load Size

50 x 50 x 80 in

Performance Maximum Load Weight

4000 lb | 1814 kg

Performance Production Speed

Up to 35 Pallets/hours

Service Requirements Alternating Current Ac Voltage

208 to 240 V

Service Requirements Current

20 A

Service Requirements Frequency

60 Hz

Service Requirements Number Of Phase

3

Service Requirements Pneumatic Service Requirements At 80 Pounds

3 ft³/min

Specifications Brand

Phoenix

Specifications Variable Load Handling Wrapping Speed

0 to 12 rpm

Specifications Warranty

10 Years-Frame | 3 Years-All Parts