Polyflow Depth Cartridges

Polyflow Depth Cartridges

SKU:DEP-6d9ac9

High-performance Polypropylene Depth Cartridges with exceptional retention efficiency and chemical compatibility.

Regular price

$39.99

Regular price

Sale price

$39.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Polyflow Depth Cartridges are pleated polypropylene absolute-rated filters designed for superior dirt-holding capacity and long-lasting performance. Engineered with an exclusive calendaring process, these cartridges offer high retention efficiencies, low extractables, and broad chemical compatibility. Suitable for various applications including general water filtration, beverage clarification, and RO/DI prefiltration, these cartridges can be steam sterilized and are compatible with most sanitizing agents.

Product Specifications

Applications 0

General water filtrationBeverage/wine clarificationRO/DI prefiltrationWaste water

Benefits 0

Low extractablesAbsolute particle retention provides excellent protection for downstream filtersBroad chemical compatibility allows use in most applicationsHigh flow rate, long service life reduces processing time

Materials Of Construction Depth Media Material

Polypropylene

Materials Of Construction Structure

Polypropylene

Materials Of Construction Support Layers

Polypropylene

Note 0

Specifications are subject to change without notificationPolyflow® is a registered trademark of Parker Hannifin Corporation.Viton® is registered trademark of E.I. DuPont de Nemours & Co., Inc.Cuno® is a registered trademark of Cuno Inc.

Specifications Effective Filtration Area Per 10 Inch 250 Mm Cart

4.9 ft² | 0.46 m²

Specifications Effective Filtration Area Per 5 Inch 130 Mm Cartr

2.4 ft² | 0.22 m²

Specifications End Fittings

222/Recessed Endcap

Specifications Filter Rating

0.6 µm | 1.2 µm | 2.5 µm | 5.0 µm | 10.0 µm | 20.0 µm | 40.0 µm

Specifications Filtration Cleanliness

Cartridge extractables NVR < 35 mg per 10 inch (250 mm) cartridge

Specifications Filtration Ratings

The 0.6 µm offers typical retention up to 99% efficiency. 1.2 µm, 2.5 µm, 5 µm, 10µm, 20 µm, and 40 µm are up to 99.9% efficient at specified pore size

Specifications Gasketo Ring Material

Buna N | EPDM | FEP Encapsulated Silicone (O-Rings only) | FEP Encapsulated Viton® (O-Rings only) | None | Silicone | Viton®

Specifications Insert Style

None (STD)

Specifications Maximum Forward Differential Pressuretemperature

80 psid | 5.5 bar

Specifications Maximum Operating Temperature

160 ºF | 71 ºC

Specifications Maximum Reverse Differential Pressuretemperature

40 psid | 2.8 bar

Specifications Nominal Length

20 in | 500 mm

Specifications Thickness Gaskets Only

0.125" (3 mm) | 0.200" (5 mm) | (1) 0.200" (5 mm) & (1) 0.125" (3 mm) | No Gasket

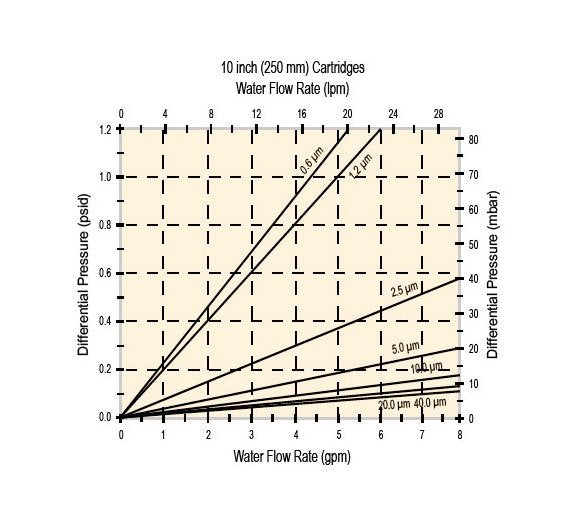

Specifications Water Flow Rates

0.6 µm - 4.2 gpm/psid (23.3 lpm/100 mbar) | 1.2 µm - 5.0 gpm/psid (27.4 lpm/100 mbar) | 2.5 µm - 13.5 gpm/psid (74.1 lpm/100 mbar) | 5.0 µm - 26.0 gpm/psid (142.7 lpm/100 mbar) | 10.0 µm - 40.0 gpm/psid (219.6 lpm/100 mbar) | 20.0 µm - 50.0 gpm/psid (274.4 lpm/100 mbar) | 40.0 µm - 60.0 gpm/psid (329.3 lpm/100 mbar)

Steam Sterilizable And Sanitizable 0

Cartridges can be steam sterilized for multiple cycles at 266ºF (130ºC) or sanitized for at least ten 30-minute cycles with 176ºF (80ºC) water. They are compatible with most sanitizing agents.

Technical Support And Product Information 0

Parker provides our customers with unsurpassed product consistency and cost efficiency. Our experienced professionals can help you select the right solution for your application. Orders can be emailed directly to PAFsales@parker.com. For additional information contact your local distributor. Information on product specifications, applications and chemical compatibility can be found on our web site at www.parker.com or through the Oxnard office.Parker designs and manufactures an extensive line of innovative solutions for specific applications in the Microelectronics, Biopharmaceutical, Food and Beverage, Coatings and Inks, Process and Chemical industries.