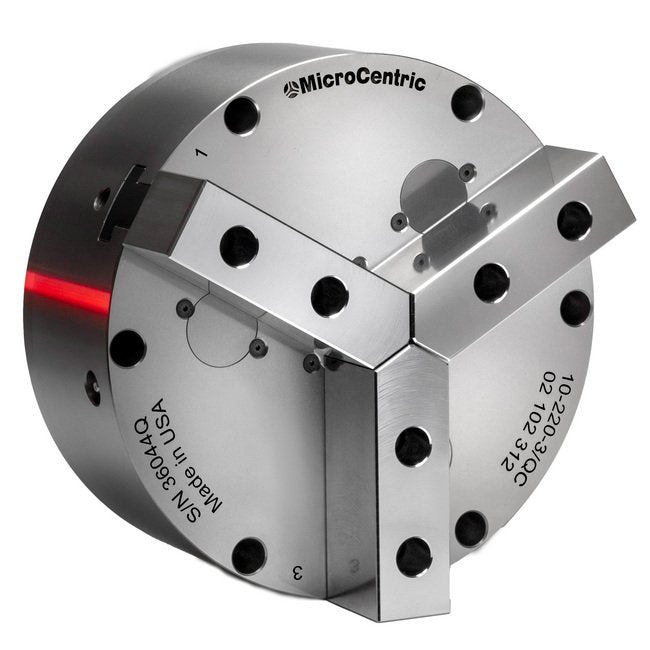

Precision Large Diameter Air Chucks

Precision Large Diameter Air Chucks

SKU:PRE-4c3c8a

Achieve precise clamping for large diameter workpieces with our high-accuracy Large Diameter Air Chucks. Perfect for precision machining needs.

Regular price

$1,699.99

Regular price

Sale price

$1,699.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Precision Large Diameter Air Chucks are ideal for machining large diameter precision and thin-walled workpieces with high accuracy and adjustable clamping force. Available in three jaw, two jaw, and six jaw configurations, these chucks offer Chuck Accuracy of .0002" (.005mm) TIR as standard, with an optional .0001" (.0025mm) TIR for precision requirements. With features like extended jaw stroke, customizable air ports, and various special configurations, these chucks ensure reliable and precise clamping for diverse machining needs.

Product Specifications

Options For Microcentric Chucks Al Automatic Lubrication Option

Lubricate the chuck with an electric pumpThe AL option allows lubricant to be supplied to the chuck through the air tube assembly during the machine cycle. This option is recom mended for unmanned machine cells and other high volume production applications.An AL chuck is equipped with a special center housing that channels the lubricant to the moving components within the chuck. The machine's way lubrication pump is typically used to also supply lubricant to the chuck.For rotating applications a rotary union must be adapted to the air tube assembly in order to provide a connection for the lubrication line. The AL Option is also available on Stationary Chucks.

Options For Microcentric Chucks Bp Back Ported Option

Air passages through the back cover provides a hole in the center of the chuckFor applications where the workpiece must be swallowed into the center of the chuck. The BP design also enables housings with part stops or parts ejectors to be mounted into the ID of the chuck.Air is typically supplied to BP chucks through the mounting plate which can be supplied with the chuck.

Options For Microcentric Chucks Qc Quick Change Top Jaw System

Patented jaw locating system reduces setup time by maintaining .0002" (0.005mm) TIR accuracy after jaw change, without remachining top jaws.MicroCentric's QC precision locating jaw system reduces setup time and increases a machine's flexibility for JIT scheduling by eliminating the time consuming process of remachining top jaws after change over. QC top jaws can also be machined "off-line" on a QC Jaw Turning Fixture or on another QC chuck.QC System Accuracies .0002" TIR when jaws are machined and replaced on the same chuck. .0008" TIR when jaws are machined on another chuck or on a QC turning fixture. QC System Features Blank QC top jaws are made from A-2 tool steel that can be hardened to Rc 60 without distorting the tapered locating holes. QC Jaw Turning fixtures are available to machine top jaws "off-line" and maximize a machine's run time. Custom hardened and ground QC top jaws can be designed for specific workpiece applications are quoted on request. QC System DesignQC top jaws are located by two tapered locating buttons that are pressed into jig ground locating holes in the chuck's base jaws. QC top jaws feature jig ground tapered locating holes that mate with the tapered locating buttons on the chuck's base jaws. Due to the close tolerances that are held on both the tapered locating buttons and locating holes, the top jaw seats on the OD of the button as well as on the face of the master jaw. This precision fit eliminates clearance and assures high locating accuracy and rigidity.

Options For Microcentric Chucks Up Ultra Precision Option

Repeating accuracy to .000020" (0.0005mm) TIRFor applications which require extremely close chucking accuracy, MicroCentric will selectively fit and certify a chuck to an accuracy of .000050" (0.001mm) or .000020" (0.0005mm) depending on model.Note that temperature variations, changes in air pressure, spindle runout, and the condition and design of top jaws will affect chuck accuracy.

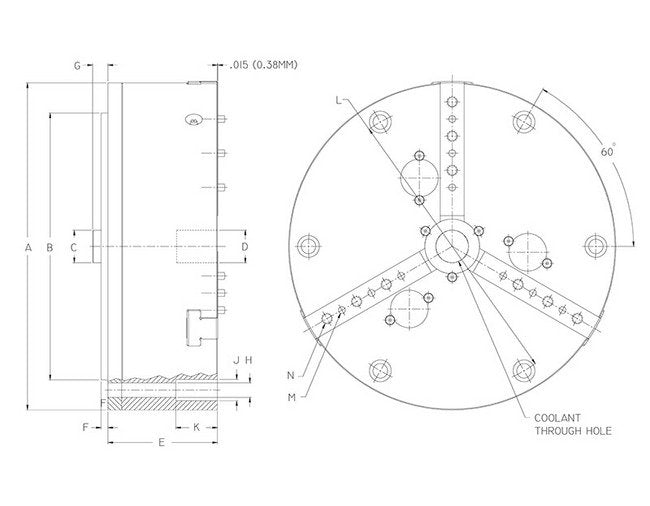

Specifications A Dimension

13.950 in | 354.3 mm

Specifications B Dimension

11.000 in | 279.4 mm

Specifications Chuck Accuracy

.0002 in | .005 mm

Specifications Chuck Size

14 in | 350 mm

Specifications Chuck Weight

156 lb | 70.8 kg

Specifications C Dimension

1.188 in | 30.2 mm

Specifications E Dimension

4.125 in | 104.8 mm

Specifications F Dimension

0.250 in | 6.4 mm

Specifications G Dimension

0.418 in | 10.6 mm

Specifications H Dimension

0.656 in | 16.7 mm

Specifications Item No

01 142 301

Specifications Jaw Stroke

.220 in | 5.6 mm

Specifications J Dimension

1.000 in | 25.4 mm

Specifications K Dimension

0.700 in | 17.8 mm

Specifications L Dimension

12.500 in | 317.5 mm

Specifications Max Air Pressure

100 psi | 0.7 MPa

Specifications Max Clamp Force

20,640 lbs | 91.9 kN

Specifications Max Rpm

2,250

Specifications M Dimension

0.250 in | 6.4 mm

Specifications No Of Jaws

3

Specifications N Dimension

M10

Standard Equipment 0

All Large Diameter Air Chucks include: One set steel top jaws