Probes

Probes

SKU:PRO-4ca827

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

For coating thickness measurementsHigh-Precision ProbesThe heart of any electromagnetic measurement system is the probe; the quality of its signal ultimately determines the overall quality of the metrological solution. The probe is a very complex system, which performs the conversion of the appropriate measuring method: In this case the coating thickness is transformed into an electrical signal (count rate, frequency, voltage) in order to display the value of the coating thickness in the instrument display.

Product Specifications

Additional Information

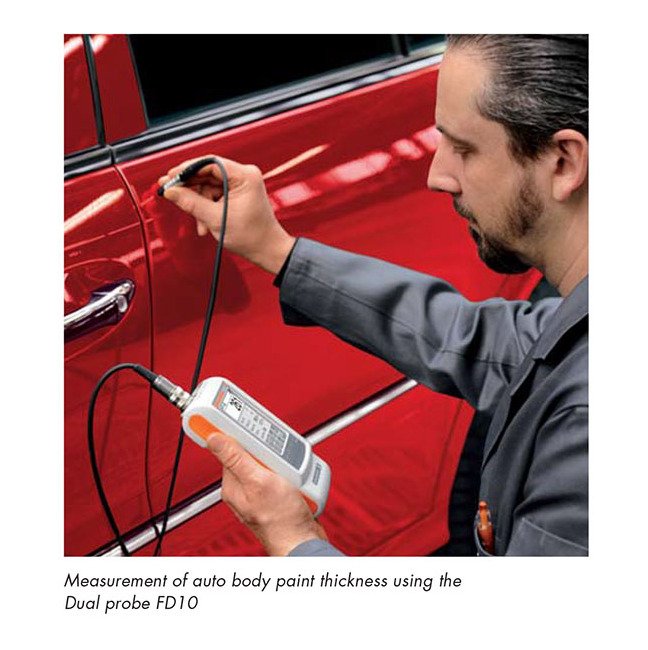

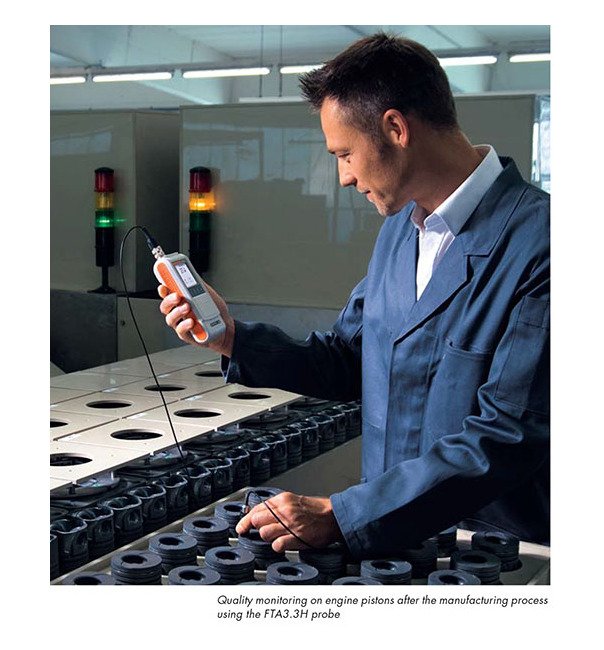

NoteThis document describes probes with electromagnetic measuring methods, which are most frequently used for coating thickness measurement. FISCHER also offers probes for material testing, e.g. for measuring the electrical conductivity or for the determination of the ferrite content. You can find a description of these probes for material testing in the documents of the corresponding measuring instruments.Solutions for individual measurement tasksWe offer the ideal probe for each individual measurement task. FISCHER engineers develop customer-specific probe constructions on demand, like the cavity probe V3FGA06H. This probe was specially designed for non-destructive measurements of EPD coatings within the box section of auto bodies - without having to cut the auto body itself.The extensive selection of FISCHER probes is as versatile as the measurement applications of our customers. After years of continuous development and innovation, the FISCHER probe program now encompasses some 100 probes designed to ensure optimal results for the widest range of measurement applications.Probe selection based on several criteriaMaterial combination of coating and base materialThickness of coating and base materialDimension of the measurement areaShape of the specimenSurface condition of the measurement areaISO 9001In keeping highest standards of quality and customer satisfaction, all members of the FISCHER Group are certified according to ISO 9001.FISCHER Germany is accredited as a DAkkS calibration lab for the measured quantity "mass per unit area" according to DIN EN ISO/IEC 17025.Quality monitoring on engine pistons after the manufacturing process using the FTA3.3H probeAuto body in section to show how the probe measures the EPD coating within the auto bodyMeasuring with the internal probe FAI3.3-150

Features

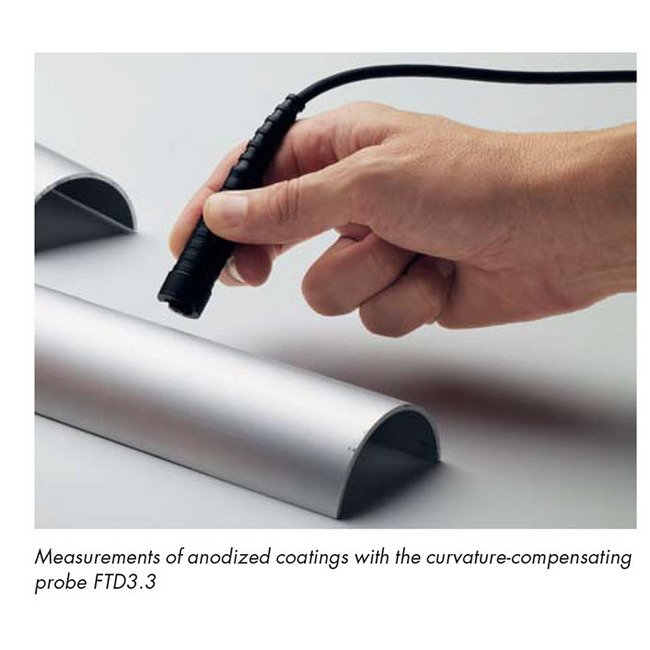

RobustFISCHER probes are extremely robust and wear-resistant - they deliver precise measurements over a long period of time even on hard surfaces and after millions of uses.In-house development and manufacturingAll probes are developed and manufactured in house to strict quality standards.Factory-calibrationEach individual probe is factory-calibrated at several reference points with the greatest care to ensure the highest possible degree of trueness.Electrical conductivity compensationFISCHER's patented conductivity compensation - used in all eddy current probes - makes it possible to adjust for different conductivities of the base material, e. g. different aluminum alloys, eliminating time-consuming on-site calibration on the actual base material while simultaneously achieving very high levels of trueness.Curvature compensationSpecial probes for the eddy current method are available that automatically compensate for the influence of curvature on rounded specimens.Reduction of measurement errorsA spring-loaded system ensures that the probe is always placed on the surface with the same pressure. This reduces measurement errors and increases the repeatability precision. Many of our probes are equipped with this spring loaded system. As a result, soft surfaces can also be measured.

Manual Or Automated Measurements

Hand-held probesBuilt-in probes for automated measuring systems

Specifications Diameter

2 mm | 78.7 mil

Specifications High Specimen Temperature

0 to +80 ºC | 0 to +176 ºF

Specifications Intended Application

Coating Thickness

Specifications Measurement Areas

30 x 30 mm | 1.18 x 1.18 in

Various Base Materials

Iron and steelNon-ferrous metalsVarious metalsSteel under Duplex coating systemsEpoxy and plastic

Various Coating Harnesses

Hard coating materials (metallic coatings like chrome etc.)Softly coated materials (paint, lacquer, textiles etc.)

Various Measuring Sites

Flat, even surfacesEasily reachableIn boreholesIn grooves and cavitiesOn curved surfaces and on cylindersHumidity ambient

Various Probe Tip Designs

For different surface characteristics such as rough surface, soft coating material etc:Single probe tip or double probe tipsRound or even pole tipsDifferent probe tip sizesDifferent probe tip materials, e.g. hard metal, jewel, TiN/TiC, PVD, hard plastic

Versatile Fields Of Applications

Measurement of the corrosion protection coating in plastics on steel pipes with the probe FKB10Measurements of anodized coatings with the curvature-compensating probe FTD3.3Measurement of zinc powder coating with the two-pole probe V7FKB4Measuring of duplex coatings with the probe FDX13HAutomated measurement of the chrome coating on piston rods with the probe V2FGA06HMeasurement of auto body paint thickness using the Dual probe FD10

Versatile Probe Program

A probe needs specific properties for each field of application for achieving best results with a high accuracy.