R-HYBRID 1575 Variable Geometry Hydraulic Plate Roll Machine

R-HYBRID 1575 Variable Geometry Hydraulic Plate Roll Machine

SKU:PLA-065cf9

Upgrade your plate bending capabilities with precision and power using the R-HYBRID 1575 Variable Geometry Hydraulic Plate Roll Machine.

Regular price

$84,999.00

Regular price

Sale price

$84,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

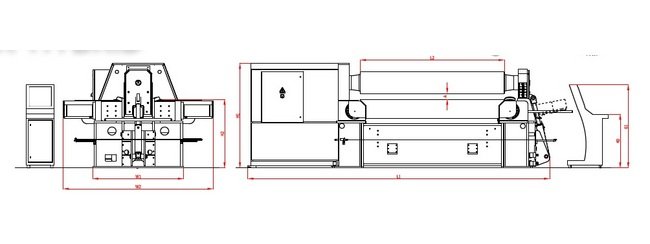

Upgrade your plate bending capabilities with the R-HYBRID 1575 Variable Geometry Hydraulic Plate Roll Machine. Designed with the innovation of a press brake, this machine offers extreme rolling precision and flexibility. Featuring a top roll diameter of 15.75 inches and a top roll bending force of 176 tons, it can easily handle medium to thick plate bending tasks. With advanced features like variable geometry type rolls movement and high stroke top roll, this machine ensures optimal performance and efficiency for your bending needs. Whether for industrial or institutional use, the R-HYBRID 1575 is a reliable and powerful solution for demanding fabrication requirements.

Product Specifications

Note

The mentioned values above is only works for 38 KSI yield point material.Different material types and plate widths; can be calculated with RMT Roll Bending Calculator.Conical bending capacities depends on cone angle and half value of mentioned values above.Weight and motor powers may increase with optional features.Due to ongoing product development, specifications may change at any time.

Optional Features

NC Control UnitAll axis positioning with adjustable speed on NC machinesAISI 4140 High strength alloy steel rollsGround rollsVariable speed controlWired or wireless remoteOil coolerOil heaterHydraulic side support system (both sides)Vertical overhead support systemPreparation for vertical support systemMaterial feeding table (Idle or motorized)Plate alignment unitSeparated power cabinChangeable top roll for smaller DiameterAutomatic central lubricationsAutomation systemSpecial roll crowningSpecial applications for wind tower production

Specifications Bending Length L2

12 ft 1 in.

Specifications Height H1

77 in

Specifications Hydraulic Tank Capacity L

106 gal

Specifications Length L1

274 in

Specifications Lower Roll Diameter

14.17 in

Specifications Main Motor Power

50 hp

Specifications Maximum Pass Through A

4 in

Specifications Minimum Interior Diameter D D X 15 Pre Bending Ca

5/8 in

Specifications Minimum Interior Diameter D D X 5 Bending Capacit

1 in

Specifications Minimum Interior Diameter D D X 5 Pre Bending Cap

3/4 in

Specifications Number Of Rolls

3

Specifications Top Roll Bending Force

176 Tons

Specifications Top Roll Diameter D

15.75 in

Specifications Total Width W2

106 in

Specifications Weight

49,706 lb

Specifications Width W1

65 in

Specifications Working Height H2

50 in

Standard Features

Variable geometry type rolls movement.PLC control unitDual speedCone bending with dual cone bending roller bearingInduction hardened rolls (HRC 54-58)AISI 1050 Carbon steel rolls machined by CNC Lathes with optimal crown (special crown upon request)Polished rollsTop and lower rolls electronically positioned and synchronized with PLC and high-end precision digital scalesHigh stroke top rollBraking system on side rollsProtected slide surfacesMachine body constructed of stress-relieved high yield steelRolls seated in spherical bearingsTop roll hydraulic opening device (drop end) with easy pull out systemTop roll driven with hydraulic motor and planetary gear boxSafety barrierElectrical and hydraulic protection against overloadsWorld standard electrical and hydraulic components (parts stocked by RMT or available off-the shelf from your local supplier)Adjustable hydraulic pressure on bottom roll (crowning compensation)Mobile control panelManual lubricationWelding possibility on the machine