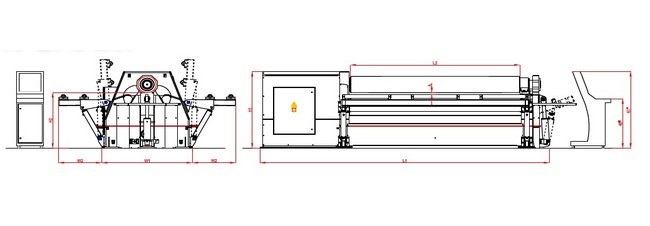

R-SMART 6-591 Hydraulic Four Rolls Bending Machine

R-SMART 6-591 Hydraulic Four Rolls Bending Machine

SKU:PLA-0e7831

R-MT 6-591 Hydraulic Four Roll Bending Machine: Precision, Efficiency & Flexibility for heavy-duty applications.

Regular price

$48,999.00

Regular price

Sale price

$48,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The R-SMART 6-591 Hydraulic Four Rolls Bending Machine from RMT is engineered for unparalleled precision and efficiency. Designed for heavy-duty applications, this machine features a robust steel frame and fully hydraulic operation. With a top roll diameter of 5.91 inches and conical bending capabilities, it offers exceptional flexibility for material ranging from 24 gauge to 5/8 inch. Benefit from advanced features like planetary side roll movement, CNC control options, and universal machinery customization, ensuring safety, reliability, and superior bending accuracy. Ideal for workshops requiring seamless production processes and high-performance plate rolling.

Product Specifications

Additional Information

The R-SMART machine is available from 3'-13' lengths making it very flexible for a wide range of applications, so you get the right machine for your needs… Not a one size fits all approach.

Benefits

The fastest and most accurate bends are made by four roll machines. The plate is held securely in place between the top and bottom rolls while the side rolls move vertically to create the bend.The bottom roll moves up to hold the plate edge securely against the top roll while the side roll is raised to form an accurate pre-bend, minimizing the flat zone on the plate edge. Pre-bending on a double pinch three roll machine requires that plates be tilted down as they are being fed. In contrast, plates are loaded horizontally at the feed level for pre-bending on a four roll machine, which allows the use of horizontal motorized roller tables to help feed the plate.Plate feeding can take place on either side of a four roll machine. If fed from only one side, they can even be placed up against a wall to save floor space.The side rolls are positioned to the right and left of the bottom roll and are on their own axes. The independent axis of each roll helps make a perfect bend. The "back" side roll (at the far side of the feeding point) also functions as a back gauge to square the plate for proper alignment (see figure 1). This eliminates the need for someone to assist the operator.The plate is kept square without slipping during both pre-bending and rolling because of the constant secure clamping of the top and bottom rolls.Four roll machines do not require the operator to remove, flip, and then try to square the plate a second time after pre-bending, as is the case with three roll initial pinch (IP) machines. Keeping the material in the machine makes four rolls 50% more efficient than three roll IP machines, and allows a cylinder to be rolled to the required diameter immediately following pre-bending.Bending the back edge takes place after the cylinder is rolled, for a one direction, single pass operation.Cone rolling is easier on a four roll machine. The side rolls can be tilted to establish the cone angle and the bottom roll can also be tilted to clamp and drive the plate.Four roll machines are the only type of plate rolls that can effectively make use of NC and CNC controls because of the constant clamping and driving of the material during all steps of rolling. Bending difficult shapes like polycentric or elliptic work pieces can be easily done with CNC four roll machines.AccuracyRMT machines are designed with state-of-the-art technologies that provide unparalleled accuracy and precision. This is the result of our world-class Research and Development department that has been constantly perfecting our machines for decades, allowing us to consistently outperform competitor machines year after year.ReliabilityRMT machines are designed from the ground up by our expert engineers with only one goal: to build the best machines imaginable. By combining our unique machine designs with the highest quality materials available, we realized our goal and invented some of the most reliable and durable machines in the world!EfficiencyWe understand the importance of a disruption-free production to your success, and have done everything in our power to maximize the efficiency of our RMT machines. We have meticulously identified and removed every hindrance to efficiency in our machines, providing you with the most seamless manufacturing experience imaginable.SafetySafe operation of heavy machinery for the operator and any bystanders is paramount to any successful enterprise, which is why RMT machines have a multitude of safety features in place, oft-times exceeding industry standards. We have even implemented our own innovative safety features when existing ones were inadequate or non existent.FlexibilityRMT is committed to the universalization of machinery and machine tools, because it not only prevents our customers from having to reinvest in new tooling and accessories, but allows for remarkable flexibility. The enhanced flexibility and longevity of our machines provides for a significantly broader range of applications, maximizing value.CustomizabilityRMT machines are highly customizable and because RMT manufactures our own designs, we have the capability to tailor-make machines to fit our customers needs. Put us to the test and see what we can come up with to help you complete difficult or otherwise impossible jobs. Regardless of the project, RMT can help realize it!

Note

The mentioned values above is only works for 38 KSI yield point material.Different material types and plate widths; can be calculated with RMT Roll Bending Calculator.Conical bending capacities depends on cone angle and half value of mentioned values above.Weight and motor powers may increase with optional features.Due to ongoing product development, specifications may change at any time.

Optional Features

NC Unit (Simple CNC)CNC Control Unit with color graphical controlAISI 4140 High strength alloy steel rollsFour rolls driveWired or wireless remote controlOil coolerOil heaterSide support system (both sides)Vertical hydraulic overhead support system 4, 6, 8 TON (10' - 14' - 16' - 20' tall)Preparation for side or vertical support systemNC inclusion for vertical support control (Available on CNC control)NC inclusion for side support control (Available on CNC control)Plate alignment unitAutomation systemChangeable top roll for smaller diameterSpecial roll crowningSpecial plate support systemsAutomatic central lubricationMaterial feeding table (Idle or motorized)

Specifications Bending Length L2

6 ft 8 in.

Specifications Bottom Roll Diameter

5.91 in

Specifications Height H1

45 in

Specifications Hydraulic Tank Capacity

24 gal

Specifications Length L1

142 in

Specifications Maximum Pass Through A

1/2 in

Specifications Minimum Additional Top Roll Diameter

5.51 in

Specifications Minimum Interior Diameter D D X 15 Pre Bending Ca

1/8 in

Specifications Minimum Interior Diameter D D X 3 Bending Capacit

5/32 in

Specifications Minimum Interior Diameter D D X 5 Bending Capacit

3/16 in

Specifications Motor Power

5.5 hp

Specifications Number Of Rolls

4

Specifications Side Rolls Diameter

5.12 in

Specifications Top Roll Diameter D

5.91 in

Specifications Weight

5,930 lb

Specifications Width Of Side Support W2

22 in

Specifications Width W

39 in

Specifications Working Height H2

35 in

Standard Features

Planetary type side roll movement.PLC Electronic balancing systemCone bendingInduction hardened rolls (HRc 56±4)Polished rollsSingle speed control of all axisDual speed control of all axis (NC machines)Variable speed control of all axis (CNC machines)Machine body constructed of stress-relievedHighly durable carbon steel rolls machined by CNC Lathes with optimal crown (special crown upon request)Rolls seated in spherical bearings and bronze bushingsHydraulic bracket (drop end) with easy pull out systemTop and bottom rolls driven with hydraulic motor and planetary gear boxAutomatic rolls peripheral speed compensation (optimum distribution of torque)Adjustable hydraulic pressure on bottom roll (crowning compensation)Emergency stop wire around the machineElectrical and hydraulic protection against overloadsWorld standard electrical and hydraulic componentsMobile control panelManual lubricationWelding possibility on the machine