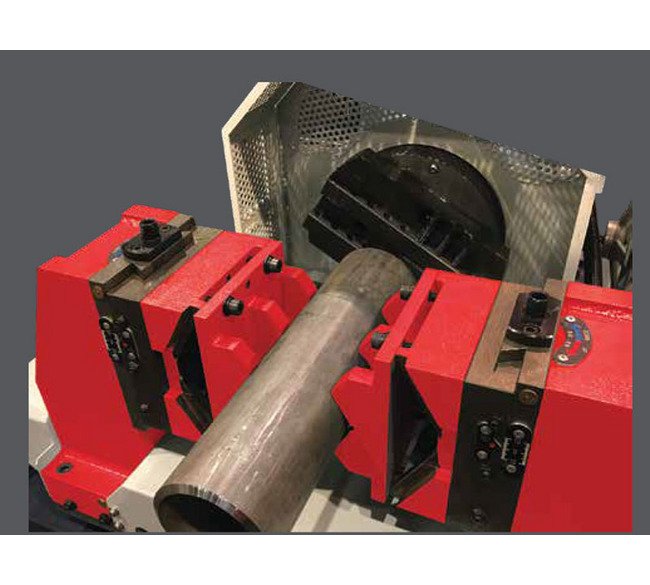

RMT PIPE SPOOL MASTER Series Pipe Facing Machine - 1-8in OD Beveling Cutter

RMT PIPE SPOOL MASTER Series Pipe Facing Machine - 1-8in OD Beveling Cutter

SKU:PIP-e6a6f0

Enhance pipe fabrication efficiency with the RMT PIPE SPOOL MASTER Beveling Machine. Ideal for 1-8in OD pipes. Precision bevels. Improved productivity.

Regular price

$2,999.99

Regular price

Sale price

$2,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The RMT PIPE SPOOL MASTER Series Pipe Facing Machine offers unparalleled efficiency in beveling and cutting tasks, accommodating pipe sizes from 1 to 8 inches OD. Featuring a robust construction and a myriad of cutting options including V, U, J, and C bevels, this machine is a game-changer for pipe fabrication shops. With CNC control options, quick setup times, and exceptional accuracy, it enhances productivity, reduces setup times, and ensures precise results. Elevate your pipe fabrication capabilities with the RMT PIPE SPOOL MASTER Series.

Product Specifications

Benefits

The pipe fabrication industry has been a backbone of American growth and infrastructure for well over two-hundred years. Pipelines, oil, energy, medical, food and paper have all grown due to the work done by pipe fabricators. It's full of the grittiest and most talented welders in the world.However, the technology that exists in today's pipe shop hasn't changed much in decades. The capacity to put complex bevels on basic carbon pipe and even harder P91 Chrome Alloy pipe has been a mix of old boring mills, hand machining and plasma/oxy processes. They're slow, burdensome and are usually the bottleneck of any shop pushing out any decent amount of pre-prepped pipe, as well as accuracy and quality issues when trying to complete a J or U bevel with any complexity.Introducing you to the RMT PIPE SPOOL MASTER Series of pipe facing lathes. Many shops, depending on equipment, will put out 1-4 larger diameter pipes a day with the machined bevel quality required; taking anywhere from 1-4 hours per pipe to set up and "machine" the end of the pipe. The new RMT PIPE SPOOL MASTER Series machines can reduce that time down to 15-30 minutes including setup. The machine does not spin the pipe, but rather clamps and centers the material, while a facing head spins and approaches the material while inside the machine. 12" XH wall (1-1/2") P91 pipe processed with a complex bevel including C-dimension was processed in 20 minutes.The RMT PIPE SPOOL MASTER Series of machines can dramatically increase your shop's capacity and output, giving you a huge advantage over your competitors and increasing your profitability; all while taking up minimal floor space and overhead.Contact your RMT Rep today to find out more!

Machine Dimensions Machine Height

58 in

Machine Dimensions Machine Length

47 in

Machine Dimensions Machine Width

39 in

Main Features

Working area lightsAdjustable + Replaceable cutting tools and insertsReplaceable clamp holders for various sizes, elbows, flange'sAuto cantering clampsTrue pipe canteringSealed clamping guidesStress relieved welded robust frameHeavy duty facing head drive systemStandard: CNC Control Unit - Easily Programming Interface with Simple Programming Menu-Facing, Single Bevel, Double Bevel, Single V, Double V, Single J, Double J, Single-U, Double U, Compound, J Prep, J-prep with Back Bevel, Compound J-prep with Back BevelOptional: CNC (Fanuc) for added threading functions (if required)True pipe canteringClamp adjustmentClamping control buttonsSmall footprint

Specifications Application

Beveling | Threading

Specifications Complex Bevels U J And C Dimensions

Hard Tooling

Specifications Machine Capacity Outside Diameter Od

1 to 8 in

Specifications Main Motor Power

5 hp

Specifications Maximum Spindle Speed

400 rpm

Specifications Optional Followertracer Attachment

If pipe is out of spec - round or oval, attachment will trace pipe to meet customer specifications

Specifications Standard Bevels Any

V Bevel (30º and 37.5º)

Specifications Wall Thickness Capacity One Setup

0.28 in

Specifications Weight

2,000 lb

Specifications X Axis Stroke

Manual Adjustment Across Facing Head

Specifications Z Axis Stroke

5 in