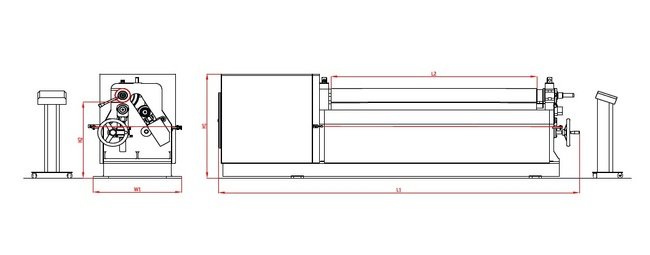

RMT R-ECO-D 5/16" Bending Capacity Motorized Three Rolls Bending Machine

RMT R-ECO-D 5/16" Bending Capacity Motorized Three Rolls Bending Machine

SKU:PLA-04dcaa

Efficient and precise RMT R-ECO-D Series Bending Machine for small part bending needs, compliant with institutional standards.

Regular price

$9,999.99

Regular price

Sale price

$9,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The RMT R-ECO-D Series Bending Machine is a premier solution for small part bending requirements with low operational costs. This machine boasts a robust construction with options for cast iron or steel welded frames, ensuring durability and reliability. Powered by helical gearbox-driven top and bottom rolls, precision bending is guaranteed, aided by optional features like a Digital Read-Out for rear roll and induction-hardened rolls. This machine meets institutional procurement standards with its adherence to industry-specific certifications and TAA compliance, offering a cost-effective and efficient bending solution for a range of applications.

Product Specifications

Additional Information

RMT R-ECO series initial pinch plate rolls are generally for lighter capacity applications and come in manual, motorized or hydraulic. They work by "pinching" the flat sheet between top and bottom rolls while the side (back) roll moves upward to contact and then bend the sheet. When rotation of the rollers is activated, the sheet exits at a given radius. With the sheet cut to the developed length and the bending roll properly positioned; the part is rolled into a cylindrical form, where it can then be welded at the seam to produce a cylinder. The top roll is in a fixed position; the bottom pinch roll can move up/down to pinch the material. The side roll is also adjustable by manually, motorized or hydraulically. To remove a rolled cylinder, it must be extracted from off of the top roll. Machines are generally equipped with release mechanism on the top roll to allow extraction of the cylinder. Typical methods are either a forward tilting or releasing top roll or a removable end yoke. In most applications, these machines require removal and re-insertion of the sheet in order to pre-bend both ends. They are cost effective but in contrast may be more labor intensive in a production setting.

Note

The mentioned values above is only works for 38 KSI yield point material.Different material types and plate widths; can be calculated with RMT Roll Bending Calculator.Conical bending capacities depends on cone angle and half value of mentioned values above.Weight and motor powers may increase with optional features.Due to ongoing product development, specifications may change at any time.

Optional Features

Digital Read-Out for rear (back) rollInduction hardened and polished rollsExtended roll shafts for profile and pipe bending operationsProfile and section bending rolls setMotorized bottom roll (pinching)Segmented plastic rolls for composite bending

Specifications Bending Capacity T

5/16 in

Specifications Bending Length L2

4 ft 2 in.

Specifications Height H1

45 mm

Specifications Length L1

111 mm

Specifications Main Motor Power

5.5 hp

Specifications Number Of Rolls

3

Specifications Optional Back Roll Motor Power

4 kW

Specifications Top Roll Diameter D

7.08 mm

Specifications Weight

5721 kg

Specifications Width W

35 mm

Specifications Working Height H2

33 mm

Standard Features

Top and bottom rolls are powered by a helical type gearbox and AC motorAISI 1050 Quality Certificated steel rolls with high tensile strengthSolid steel frame.Mechanical manual mechanical drop-end.Mobile control panelConical bending deviceManual lubrication pointsTop roll support systemPrecision bending with a motor brakeMotorized adjustment of back roll