SIGMASCOPE® SMP350 Thickness Gages

SIGMASCOPE® SMP350 Thickness Gages

SKU:SIG-d2f7bc

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Measuring the Electrical Conductivity of Non-ferrous MetalsElectrical conductivity is an important material property that provides information not only about a metal's ability to conduct electrical currents but also about its composition, micro structure and/or mechanical properties. Using the SIGMASCOPE® SMP350, it is easy and quick to determine the electrical conductivity with precision and accuracy.

Product Specifications

Additional Information

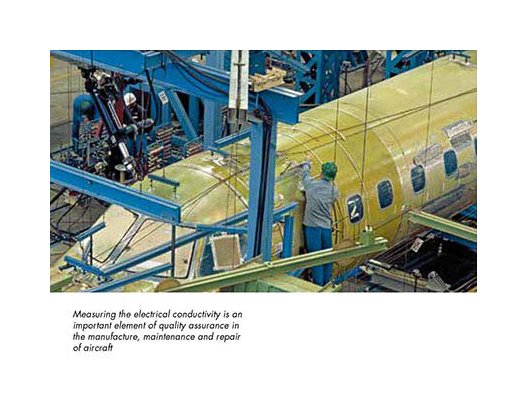

Measuring the electrical conductivity is an important element of quality assurance in the manufacture, maintenance and repair of aircraftSorting aluminum raw materialsQuality assurance to prevent color variations in anodized aluminumCertified standards for calibrating the SIGMASCOPE® SMP350, traceable to internationally-recognized calibration norms

Applications

The SMP350 can measure the electrical conductivity of any non-magnetizable metal. Furthermore, since the electrical conductivity provides data about other material properties, it is effective in a wide range of measuring applications and fields of use, including:Quality assurance and sorting of raw materialsAuthentication of coin alloys (e.g. specific conductivity of Euro coins)Assessing hardness and strength of heat-treated materialsInspecting for heat damage, material fatigue and cracksEstimating the phosphorous content in copperTracking precipitation processes, e.g. for Cu-Cr alloysTesting the homogeneity of alloysScrap metal sorting

Calibrationstandards

High-precision measurements are required to determine the electrical conductivity. Because the eddy current method is a comparative measurement method, accurate standards are necessary to calibrate the measuring instrument. Certified standards are available for the entire conductivity range.

Features

Windows™ CE operating system; large touchscreen and displayable keyboardCustomizable user interfaceVery simple calibration via user promptsSimple management of measuring applications with user-definable file and folder structureMemory for several thousand measuring applications and several thousand readingsConsideration of each material's conductivity related temperature coefficientAutomatic measurement acquisition in free-running mode or with external startGraphical presentation of specification limitsExtensive statistical evaluation of test series with date/time stamp as well as computation of Cp, Cpk and histogram presentationManual temperature inputMonitoring of temperature changes over time (ΔT/Δt)Calibration fine-tuning for instrument calibration with up to 4 standardsAcoustic signal for measurement acquisition and violation of specification limits; can be turned on/offVarious languages available

Hardware Concept

The SIGMASCOPE® SMP350 is equipped with a Windows™ CE operating system and an intuitive graphical user interface that drives a high-resolution touchscreen operable with stylus or finger. The corresponding probes are suited for different measurement frequencies. For automatic compensation of temperature influences on the measurement, the ambient or specimen temperature can be taken directly with the integrated (or optional external) temperature sensor.

Interfaces

Printer Port | Universal Serial Bus (USB)

Measurement Principle

The SIGMASCOPE® SMP350 measures the electrical conductivity using the phase-sensitive eddy current method, which is approved by both DIN EN 2004-1 and ASTM E 1004 for determining conductivity. This kind of signal evaluation allows for contact-free determination of a substrate’s electrical conductivity, even under paint or plastic coatings up to 500 μm thick. This method also marginalizes the influence of surface roughness.

Note

Included in the shipment: Carrying case, power supply, battery set, carrying strap and protective cover for the instrument, Cu reference standard, USB cable.

Optional Accessories And Spare Parts

Item #: 605-441Item Name: Measurement Probe FS24Item #: 605-209Item Name: Measurement Probe FS40Item #: 605-210Item Name: Measurement Probe FS40HFItem #: 605-211Item Name: Measurement Probe FS40LFOptional AccessoriesItem #: 603-237Item Name: Temperature Sensor TF100AItem #: 604-144Item Name: Rechargeable Battery Set

Specifications Industry Standardscertifications

American Society for Testing and Materials (ASTM E 1004) | European Standards International Organization for Standardization (DIN EN 2004-1)

Specifications Intended Application

Material Testing

Specifications International Annealed Copper Standard Iacs Measu

1 to 112 %

Specifications Lift Off Compensation

0 to 500 µm

Specifications Measurement Precision At Ambient Temperature

± 0.5% of Reading

Specifications Measurement Range

0.5 to 65 mS/m

Specifications Measuring Frequency Range

1.5 kHz to 2 MHz

Specifications Operating Temperature

0 to 40 ºC

Specifications Smallest Diameter Measurement Area Without Notice

13 mm

Technical Data

Measurements pursuant to ASTM E 1004 and DIN EN 2004-1SMP350 with probe FS40 fulfills Boeing specification BAC 5651Connector for electrical conductivity probe, with or without integrated temperature sensorConnector for optional temperature sensor TF100APower supply via battery or mains electricity