Single Passage Rotorseals with Non-Metallic Sealing Ring

Single Passage Rotorseals with Non-Metallic Sealing Ring

SKU:CLU-049ab4

High-performance Single Passage Rotorseals with non-metallic seal for reliable leak protection and easy installation.

Regular price

$399.99

Regular price

Sale price

$399.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

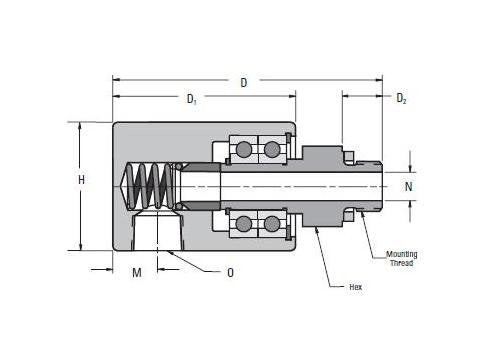

The Single Passage Rotorseals with Non-Metallic Sealing Ring are designed to provide positive protection against leakage and compensate for seal wear. With a robust construction and ball bearings ensuring rigidity and minimal running torque, these rotorseals offer versatility and convenience. Ideal for pneumatic installations, they can handle medium volume, single passage requirements effectively. Ensure minimal rotorseal wobble and easy installation with external and standard pipe threads.

Product Specifications

General Description 0

The rotating seal is established by a non-metallic sealing ring, held against the rotorseal shaft by a light spring force. The sealing ring is designed so that media pressure acts on both of its ends to minimize the force on the sealing surface.This design gives positive protection against leakage and compensates for seal wear. Ball bearings are used between the stationary and rotating ports to provide rigidity to the rotorseal assembly and to minimize the running torque.Rotorseals are available with single, dual and triple passages, in a variety of sizes and designs, to provide the versatility needed to handle most requirements. Single passage rotorseals, in pneumatic installation, can be plumbed with a quick release valve at its inlet port to provide a convenient exhaust.In most applications, the rotorseal is mounted to the end of a shaft. The shaft is rifle and cross drilled to provide a passageway for the media transmitted. It is important that the rotorseal's axis of rotation be concentric with the rotating member's axis of rotation to minimize rotorseal wobble.To accommodate eccentricities, a flexible connection must be used between the rotorseal and supply. A rigid connection will tend to preload the rotorseal bearings. The flexible connection should not be installed taut and should include a union and 45º elbow.The flexible connection should be attached to the rotorseal prior to fastening the rotorseal to the rotating body to avoid seal or bearing damage. The union connection to the supply line is made last.In most applications, only one fluid is to be transmitted to a rotating assembly. This group of rotorseals will handle most medium volume, single passage requirements. External threads on the seal shaft and standard pipe threads on the inlet port make installations an easy job.

Note 0

Operation at maximum pressure and speed should be avoided. Refer to K-14 for operating parameters.

Specifications Dimension D

4.45 in | 4.49 in | 113 mm | 114 mm

Specifications Dimension D1

3.00 in | 3.15 in | 76 mm | 80 mm

Specifications Dimension D2

0.75 in | 19 mm

Specifications Dimension H

2.38 in | 2.50 in | 60 mm | 64 mm

Specifications Dimension L2

1.00 in | 19 mm

Specifications Dimension M

0.69 in | 18 mm

Specifications Dimension N

0.63 in | 16 mm

Specifications Dimension O

0.75 in | 1/2-14 in | 1/2-14 mm | 19 mm

Specifications Dimension O1

1/2-14

Specifications Dimension U1

15.4 in | 391 mm

Specifications Dimension U2

2.3 in | 58 mm

Specifications Dimension U3

14.2 in | 361 mm

Specifications Dimension U4

12.8 in | 325 mm

Specifications Hex Size

1.375 in | 34.9 mm

Specifications Inlet Port Thread O

1/2-14

Specifications Manufacturer

Eaton-Airflex

Specifications Maximum Pressure

150 psi | 10.3 bar

Specifications Maximum Speed

3000 rpm

Specifications Mounting Size Thread

1-14

Specifications Number Of Passages

1

Specifications Passage Area

0.307 in² | 1.98 cm²

Specifications Rotorseal Type

C2

Specifications Size

C2

Specifications Weight

2.0 lb | 0.9 kg