Superlok SP Series Plug 7/8in Tube OD & 1-1/4in Width Across Flat

Superlok SP Series Plug 7/8in Tube OD & 1-1/4in Width Across Flat

SKU:SPS-04afad

Versatile Superlok SP Series Plug for metric fittings, stainless steel construction, superior hardness limitation, ideal for gas systems & high temp applications.

Regular price

$14.99

Regular price

Sale price

$14.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Superlok SP Series Plug is designed for unused ports of metric Superlok fittings, ensuring a secure seal for various applications. Crafted from high-quality stainless steel tubing meeting ASTM standards, this plug offers exceptional hardness limitation for optimal performance. Suitable for gas systems, vacuum, cryogenic, and high-temperature applications, this plug guarantees reliability and adherence to strict standards. With easy installation instructions and compatibility with industry-leading tube fittings, the Superlok SP Series Plug is a versatile and dependable choice for institutional and consumer buyers.

Product Specifications

Compatibility Compatibility

SUPERLOK® Tube fittings are designed and manufactured to be interchangeable with other Tube Fittings manufactured by other industry leading manufacturers. When required compatibility testing can be performed by an independent third party and the reports can be provided. Please consult BMT(SUPERLOK®) sales representative for compatibility.

Gas System Application Gas System Application

SUPERLOK® Tube Fittings are appropriate for Gas Systems, but the implementation of certain standards mentioned below should be adhered to just as in other systems.Tubing hardness must be less than that of the ferrules.Tubing should be free of surface imperfections, defects and round in shape.Refer to Table 2 on page 14 for selection of the appropriate wall thickness. (Only shaded areas should be selected for Gas Systems)Tubing ends must be cut squarely and perpendicular to the center-line of the tubing. After the tubing is cut it must be deburred on both the inside and outside with a High quality fully sharpened deburring tool.Follow the SUPERLOK® Installation Instructions from pages 10 to 11 in the catalog.Do not attempt to bend the tubing after a fitting has been Installed in a fixed position.Tubing Systems should be installed to allow for adequate expansion and contraction as well as ease of maintenance.

Hardness Limitation Hardness Limitation

High quality stainless steel tubing that is fully annealed; Seamless or Welded per ASTM A269, A213 or equivalent should be used with SUPERLOK® Tube fittings. The tubing must be a maximum hardness of HRB 90 or less on the Rockwell Scale, however HRB 80 is more suitable for bending and offers a greater difference in hardness to the ferrules. This difference in hardness offers more ease in assembly and better interaction between the ferrules and the tubing.

Installation Instructions Installation Instructions

Installation instructionWith wrench, 1/4 turn from finger-tight position. (1/8 turn for 1/8", 3/16", 2, 3, 4 size plug). Remove nut and ferrules from body.

Note Note

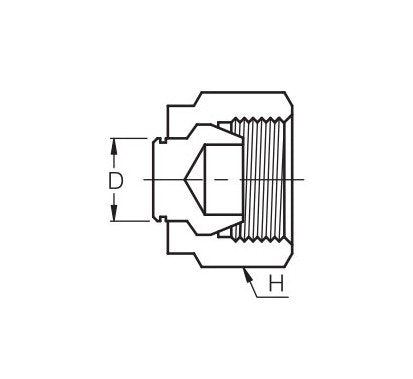

Dimensions and Drawings are for reference only and are subject to change without prior notice.Sizes, pressure classes, and end connections not listed are available upon request.Dimensions shown with SUPERLOK® nuts finger-tight, where applicable.

Technical Specs Tube Outside Diameter D

7/8 in

Technical Specs Width Across Flat H

1-1/4 in

Vacuum Cryogenic And High Temperature Applications Vacuum Cryoge

SUPERLOK® Tube Fittings have been tested in vacuum, Cryogenic and High Temperatures insuring repeatable and reliable performance in the severest of applications.