Sure Flow ASME Class 300 Line Blind - 12in, 740psi @100ºF WOG

Sure Flow ASME Class 300 Line Blind - 12in, 740psi @100ºF WOG

SKU:LIN-a75ed9

High-pressure Line Blind for ASME Class 300 systems. Resilient carbon steel construction. ASME B16.48 compliant, ideal for water, oil, gas applications.

Regular price

$299.99

Regular price

Sale price

$299.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Sure Flow ASME Class 300 Line Blind is a top-quality industrial tool designed for temporary blockage of flow in high-pressure piping systems. Constructed from durable carbon steel, this Line Blind complies with ASME B16.48 specifications, ensuring resilience under various pressure-temperature conditions. With a pressure rating of 740 psi at 100ºF for water, oil, and gas applications, this Line Blind guarantees reliable performance. Meeting stringent ASME standards and boasting a mill finish as standard, this Sure Flow Line Blind is a dependable solution for your industrial needs.

Product Specifications

Additional Information Additional Information

For Paddle Spacers, the hole diameter in the handle is 1/2" for 1" wide handles, and 3/4" for 1 1/2" wide handles. ASME B16.48 prohibits the use of indicator or bolt holes in the handles of Paddle Blinds. However, this option is available if required by purchaser.One coat of standard shop primer will be applied to all carbon steel Line Blinds unless specified differently.Mill finish is standard. Other surface finishes are available. Contact factory for options. Standard materials are: SA516 Gr.70304 Stainless Steel316 Stainless Steel Other alloys can be furnished upon requestSure Flow Equipment Line Blinds are produced in strict accordance with the following codes of practice: ASME B16.48ASME B16.5ASME B16.20ASME B16.47 (For larger diameter flanges)

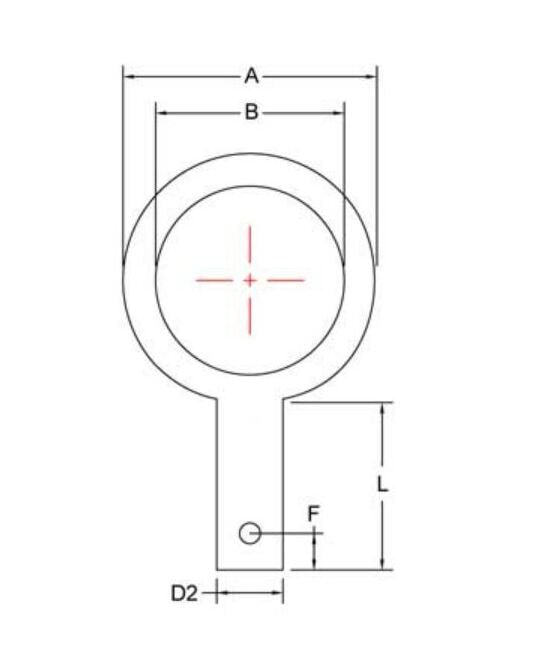

Dimensions Diameter E

1 1/4 in

Dimensions Dimension A

16 1/2 in

Dimensions Dimension B

12 3/4 in

Dimensions Dimension C

17 3/4 in

Dimensions Dimension D1

4 in

Dimensions Dimension D2

1 1/2 in

Dimensions Dimension F

1 in

Dimensions Dimension L

5 in

Dimensions Size

12 in

Dimensions Thickness

1 1/8 in

Industry Standardscertifications Industry Standardscertification

American Society of Mechanical Engineers (ASME) Class 300 | International Organization for Standardization (ISO) 9001:2008 (Intertek)

Note Note

Higher ASME pressure ratings availableLarger sizes availableManufacturer reserves the right to modify dimensions, materials, or design. Consult factory for certification.

Operating Pressures And Temperatures Pressure At 100 Degree Fahr

740 psi

Operating Pressures And Temperatures Pressure At 422 Degree Fahr

300 psi

Specifications Material

Carbon Steel

Specifications Prefix Size

1200

Technical Specifications Technical Specifications

Sure Flow Equipment Line Blind thicknesses are based on ASME B16.48 specifications and are designed to withstand any pressure â temperature combination that an ASME flange will withstand.For Paddle Spacers, the hole diameter in the handle is 1/2â for 1â wide handles, and 3/4â for 1 1/2â wide handles. ASME B16.48 prohibits the use of indicator or bolt holes in the handles of Paddle Blinds. However, this option is available if required by purchaser.One coat of standard shop primer will be applied to all carbon steel Line Blinds unless specified differently.Mill finish is standard. Other surface finishes are available. Contact factory for options.Standard materials are:SA516 Gr.70304 Stainless Steel316 Stainless SteelOther alloys can be furnished upon requestSure Flow Equipment Line Blinds are produced in strict accordance with the following codes of practice:ASME B16.48ASME B16.5ASME B16.20ASME B16.47 (For larger diameter flanges)