Tanis® CeramiX® Heavy-Duty Copper Center Wheel Brush - 4" Diameter, 80 Grit

Tanis® CeramiX® Heavy-Duty Copper Center Wheel Brush - 4" Diameter, 80 Grit

SKU:ABR-6e3514

Precisely clean, polish, and deburr with Tanis® CeramiX® Heavy-Duty Copper Center Wheel Brush - 4" Diameter, 80 Grit

Regular price

$24.99

Regular price

Sale price

$24.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Tanis® CeramiX® Heavy-Duty Copper Center Wheel Brush is designed for precise cleaning, polishing, and deburring in recessed areas. With a filament diameter of 0.055 in, brush diameter of 4 in, and trim length of 1 in, it offers superior performance. The 80 grit CeramiX® brushes, embedded with 3M™ Abrasive Grain 321, cut up to 5 times faster on ferrous metals. This brush's unique ceramic abrasive grain structure ensures enhanced cutting action, longer brush life, and increased throughput, making it ideal for bore finishing and edge burr removal. Custom sizes and grits are available to meet diverse application needs.

Product Specifications

Abrasive Grain Options

3M™ Grain 321 used in CeramiX® Brushes cuts 3 to 5 times faster on ferrous metal surfaces compared to traditional abrasive nylons. The mineral grain in CeramiX® brushes wears away in smaller chunks leaving more mineral available to continuously work on the part surface.

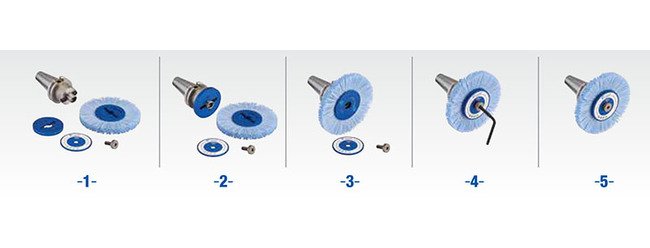

Accessories

Brush ExtensionsPart Number - 10022Compatible with Brush Arbor Holes of - 5/8 in.Length of Extension - 12 in.Brush Type - Metal Hub Wheel (5/8 in.)Note - Each part number comes with 1 extension and 3 shoulder bolts. Capable of holding up to 3 wheels. Brushes sold separatelyAir Motor ShanksDescription - For air motors and flexible shafts. Accepts single or multiple brushes.Part Number - 10033Shank Diameter - 1/4 in.Arbor Hole Size - 5/8 in.For Arbor Width Up To - 3/8 in.Overall Length - 1-7/8 in.

Additional Information

CeramiX® Abrasive Brushes with 3M™ Abrasive Grain 321A superior ceramic abrasive grain creates a superior abrasive brushThe technology dates back to 1981, when 3M™ Company (St. Paul, MN) introduced the first commercial application of sol gel abrasive grain. The advantages of this grain stem from how it’s manufactured and is evident in the grain's microstructure.The production of conventional fused abrasive grain (such as aluminum oxide or silicon carbide), is a process in which the raw materials are fused or melted together, cooled and then crushed. This process results in crystal structures that are usually quite large.In comparison, sol gel abrasive grain is the product of a chemical process in which an alumina precursor is prepared, gelled, dried, crushed into particles and then sintered to form abrasive grains. These ceramic abrasive grains may be embedded in a nylon polymer and the combination extruded into abrasive nylon filaments. The ceramic abrasive particles produced through sol gel processes have a finer crystalline structure than their conventional counterparts. Individual fused aluminum oxide abrasive grains typically comprise one to three alumina crystals; sol gel abrasive grains consist of many multitudes of alumina crystals.CeramiX® Performance with 3M™ Abrasive Grain 321Cutting ActionCeramiX® proprietary abrasive brushes provide enhanced cutting action up to 3 to 5 times faster than traditional abrasive filamentsBrush LifeThe mineral grain in CeramiX® brushes wears away in smaller pieces, leaving more mineral to work on the part surface.Increased ThroughputCeramiX® abrasive brushes reduce cycle times, enabling you to increase throughput. The controlled surface abrading action provides a consistent surface finishCrystalline StructureThe benefit of this crystalline structure is that as the outermost crystals in the abrasive grain become worn during use they are expelled in very small fragments, leaving a greater amount of grain in the filament to continue abrading the part surface. The nylon filaments containing this special ceramic abrasive grain deliver improved productivity.Two-Phase MicrostructureThe 3M™ ceramic abrasive grain 321 also has a unique two-phase microstructure, a combination of fine crystals and a platelet phase. The platelets serve to reinforce the abrasive grains to withstand greater abrasion forces. The random orientation of the platelets also deflects fractures into multiple directions, creating a jagged irregular surface after the grain fractures. This continuous self-sharpening and jagged grain surface provide superior abrasion for filaments containing 321 ceramic abrasive grainsThree Key BenefitsThree key traits which contribute to its elevated status: fracture toughness, hardness, and self-sharpening qualities. These features equate to increased productivity for CeramiX® abrasive nylon brushes, made with proprietary 3M™ 321 ceramic abrasive grain embedded throughout the filament.CeramiX® BrushesCeramiX® nylon abrasive brushes are made by Tanis®, Inc. in Delafield, Wisconsin. CeramiX® nylon abrasive brushes are used as flexible filing tools in deburring and surface conditioning applications. Their flexibility allows these brushes to conform to irregular surface shapes. Brush designs have been developed for use in power tools, robotic cells and CNC applications to eliminate the need for time-consuming and inconsistent hand deburring operations. Custom sizes available upon request.Tanis®' abrasive nylon brushes are available in multiple configurations: tube or burr brushes (also known as twisted-in-wire), strip brushes and composite formed disc, mini-disc and radial wheels. CeramiX® high-performance brushes cut 3 to 5 times faster on ferrous metal surfaces due to the properties of the 321 ceramic abrasive grain and CeramiX® performs well under high stress and heat conditions.CeramiX® abrasive nylon filament is available in 320, 220, 180, 120, 80 and 46 grit sizes, in a variety of filament diameters including a heavy-duty rectangular shape. Tanis® regularly designs and manufactures custom brushes in CeramiX® and other filaments to suit customers' specific applications.3M™ is a registered trademark of the 3M™ company. CeramiX® is a registered trademark of Tanis®, Inc.

Applications

Bore FinishingRemove Burrs from Internal Edges

Note

Additional diameters and grits available upon request.

Specifications Arbor Hole Size

5/8 in

Specifications Brush Diameter

4 in

Specifications Face Width

5/8 in

Specifications Filament

CeramiX®

Specifications Filament Diameter

0.055 in

Specifications Maximum Speed

10000 rpm

Specifications Peripheral Angular Speed

52.3 rpm

Specifications Size

80 grit

Specifications Trim Length

1 in