Texwrap OVS Series 5" Vertical Sealer

Texwrap OVS Series 5" Vertical Sealer

SKU:PAC-4c2d1f

Discover Texwrap OVS Series 5" Vertical Sealer: Seals bottles, cans, and jars vertically with precision and speed. Optimize packaging efficiency with advanced technology.

Regular price

$12,500.00

Regular price

Sale price

$12,500.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

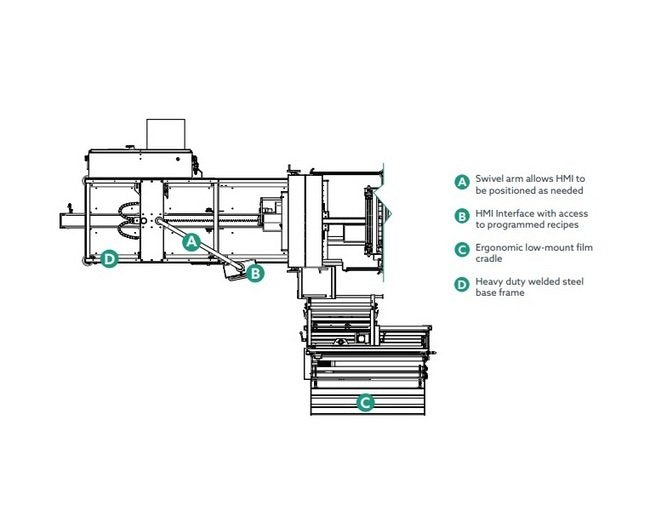

The Texwrap OVS Series 5" Vertical Sealer revolutionizes shrink packaging for bottles, cans, and jars in a vertical position. Featuring advanced Orbital Seal System and patented seal technology, it ensures rapid, precise, and consistent sealing. With options like film splice, label positioning, and servo control, it optimizes production efficiency. This USA-made sealer, with heavy-duty construction and servo-controlled features, guarantees high-quality seals and maintenance ease. Ideal for end-of-filling-line shrink packaging, it minimizes film waste, enhances product presentation, and boosts operational performance.

Product Specifications

Additional Information Additional Information

Often used to multipack for retail sale, the precise product and film control of the OVS series allows high speed operation with precise print registration. Combine with an Automatic Label Positioning System and all the labels in of a multipack of product will be facing precisely the same direction.The sealing system on these wrappers is Texwrap®âs patented servo orbitalmotion head. This eliminates the need for the carriage to move with the product while the seal is being made, which dramatically increases the throughput speed of the wrapper. In addition, they have the capability to infinitely vary the speed of the exit conveyor which allows it to be slowed momentarily as the seal is being made to relieve tension on the film for superior seals.The Texwrap® OVS Series Vertical Seal Systems are ideal for end-of-filling-line shrink packaging. Now products such as bottles, cans and jars can be wrapped while in the vertical position. The OVS Series machines use a full top or bottom trim seal instead of a lap seal to securely enclose the product. In addition to providing an outstanding seal, this eliminates the unsightly seam across the side panel of the package common with other machines. Often used to multipack for retail sale, the precise product and film control of the OVS series allows high speed operation with precise print registration. Combine with an Automatic Label Positioning System (Orientor) and all the labels in of a multipack of product will be facing precisely the same direction.The sealing head on these wrappers is Texwrap®'s patented servo orbital-motion head. This eliminates the need for the head to move with the product while the seal is being made which dramatically increases the throughput speed of the wrapper. In addition, they have the capability to infinitely vary the speed of the exit conveyor which allows it to be slowed momentarily as the seal is being made to relieve tension on the film for superior seals using the absolute minimum amount of film.Reduction of maintenance requirements is an important part of the design of every Texwrap® wrapper. These systems use âGeneration 3â servo technology meaning that it was designed from the ground up to integrate servo technology, PLC control, and the mechanical elements of the machine. The result is a fast, reliable, and flexible wrapper with minimal moving parts, minimal maintenance requirements and maximum performance.The model OVS-514 Continuous Motion Vertical Seal Wrapper uses a full bottom trim seal to securely enclose the product. In addition to providing an outstanding seal, this system eliminates the unsightly side seal across the side panel of packages common in other machines. Often used to wrap multipacks for retail sale, the precise product and film control of the OVS-514 allows high speed operation with precise print registration.The OVS-514 has a max product size of 6â W x 14â H and operates with a film speed of 200 feet per minute (FPM) and up to 120 cycles per minuteWhy Texwrap®?Texwrap®âs OVS Series systems utilize our patented orbital seal motion that ensures the machine creates a consistent, quality seal at a high speed, and are robust enough to run continuously, 3 shifts per day, 7 days a week.Texwrap®âs vertically integrated manufacturing process means all our machines are designed, fabricated, and assembled under one roof.Made in the U.S.A. quality and customer support, and our industry leading 10-Year BuiltBetter Backed-Better Warranty ensure the Lowest Total Cost of Ownership in the Industry.The TVS DifferenceThe rugged yet simple design of the patented TVS (Texwrap® Versa Seal) sealing system produces the ultimate in consistent seal quality across a broad range of film types and gauges â with little or no adjustment.Using very few moving parts, no air, and an uncoated sealing element ensures consistent seal quality with very little maintenance.Texwrap® provides high-quality stand-alone machinery and systems to produce commercially attractive shrink wrapped and shrink bundled products that are protected for storage and shipping. We provide one of the most comprehensive lines of cost-effective high-speed shrink wrapping and bundling solutions for a variety of applications including L-bar sealers, continuous motion side sealers, intermittent motion side sealers, lap sealers, and vertical wrappers, as well as tunnels, conveyors, and infeeds. We also specialize in designing and building systems for e-commerce packaging, as well as custom systems to fit unique applications for a variety of shaped products. We have a network of highly-trained packaging distributor partners to better serve our customers. These partnerships ensure the best machinery and application fit, smooth startup, reliable local service, and long-term return on investment.

Features Features

Orbital Seal SystemUtilizes Texwrap®âs Patented Orbital Seal System resulting in highest rate of speed at continuous operation.Servo Controlled Seal JawServo controlled seal jaws allowing operation at a higher rate and still maintain consistent, precision seals.Texwrap® Designed Product InfeedUtilizing its library of infeed designs Texwrap® will configure a solution to optimize product output.Centerline JustifiedEasily paired with Texwrap® infeed to provide a precise, consistent flow of product into the wrapper.Precise Product ControlFinely tuned product control through the transition zones to maximize seal strength and quality.Patented Texwrap®'s Versa Seal (TVS) bottom trim seal technology.5-axis servo controlled seal jaws allowing operation at a higher rate and still maintain consistent, precision seals.Independent conveyor control allows relaxed film at cross seal and transitions.Upstream/downstream handshaking, feeder controls, optional quick connect cable system for additional equipment.Internal scrap take up with advanced oscillating guide, film break, take up reel alarms and quick release spool.Texwrap® patented Motion Trim⢠Technology that increases throughput by the running infeed and exit conveyors while seal jaws are in motion.

Options Options

Manual Film SpliceAuto Film SpliceVacuum Scrap RemovalLabel Positioning System

Specifications Conveyor Speed

0 to 200 ft/min

Specifications Country Of Origin

Designed and manufactured in the USA

Specifications Maximum Center Folded Film Width

24 in

Specifications Maximum Package Height

14 in

Specifications Maximum Package Length

Infinite

Specifications Maximum Package Width

5 in

Specifications Note For Maximum Package Size

Both Height & Width cannot be at maximum dimension

Specifications Note For Wrapper Footprint

Does not include door clearance, swivel arm position, or other options

Specifications Optional Construction Material

Corrosion Resistant Heavy-Duty Welded Tubular Steel Construction for Wipe-Down Environments

Specifications Optional Single Wound Film Width

48 in

Specifications Orientation

Right or Left-hand configuration available

Specifications Standard Construction Material

Heavy-Duty Welded Tubular Steel

Specifications Wrapper Length

123 in

Specifications Wrapper Width

69 in