Thermal Kinetics Falling Film Tubular Evaporator

Thermal Kinetics Falling Film Tubular Evaporator

SKU:EVA-1fd406

Optimize your liquid evaporation process with our high-efficiency Falling Film Tubular Evaporator by Thermal Kinetics.

Regular price

$4,999.99

Regular price

Sale price

$4,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Thermal Kinetics Falling Film Tubular Evaporator offers unparalleled efficiency and performance in evaporating liquids within vertical tubes. With a focus on optimizing heat transfer coefficients, this evaporator is suitable for industries such as Agricultural Chemical Production, Food and Beverage, Pharmaceutical Production, and more. Its low temperature difference requirements and high heat transfer capabilities make it a reliable choice for various industrial applications.

Product Specifications

Additional Information Additional Information

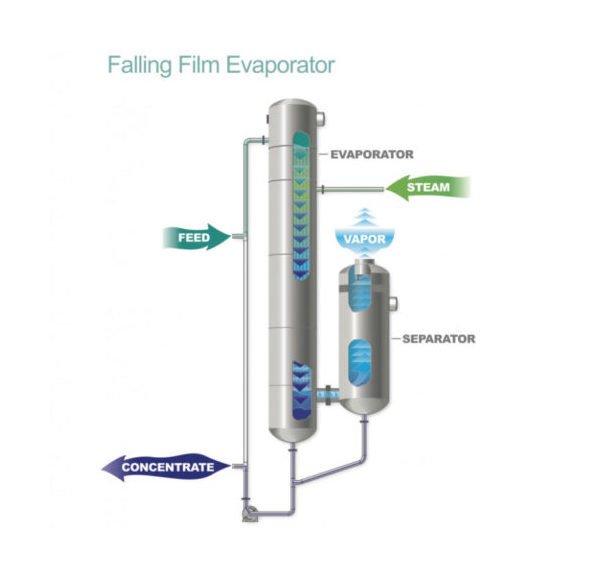

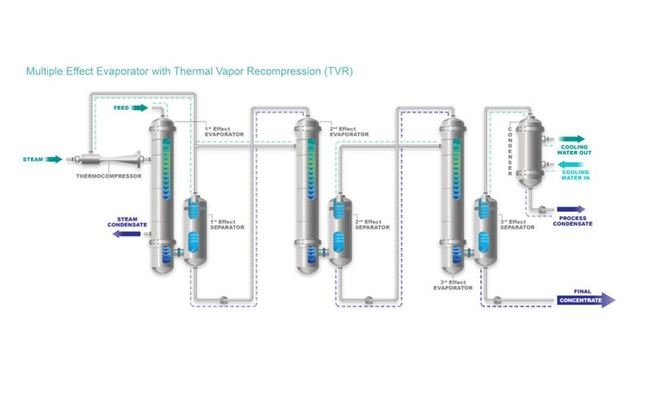

We understand what wetting rates, heat transfer coefficients, and proper distribution systems are required for long term successful operation.Evaporation technology is used in any process that requires concentration of a stream by removal of water or other solvent. The process of evaporation is energy-intensive; any evaporator system design approach needs to take great consideration into the heat recovery philosophy and overall utility usage of the final system design. Product characteristics also need to be considered in the system design; many product characteristics can be altered in an evaporation process, especially in a Food and Beverage application.Evaporation occurs inside vertical tubes through a film of liquid established using one of several liquid distribution devices, the selection of which depends on the wetting rate on the tubes.

Applications Applications

Falling film evaporators are an excellent choice in terms of providing a heat exchanger with a higher tube side coefficient than other style exchangers. These can be used in the following industry applications:Fuel Ethanol IndustryFood Processing IndustryChemical Service Industry

Components Components

Condenser | Heat Recovery Exchangers | Main Evaporator Heater | Vacuum System | Vapor/Liquid Separator

Falling Film Versus Risingfalling Film Falling Film Versus Risin

Falling Film Tubular EvaporatorLiquid to be boiled enters at the top of the exchanger.An internal distributor ensures the tubes are equally wetted.The liquid forms a film along the inside of the tubes.The tubes are therefore not flooded.Fluid boils as it passes down the tubes.Vapor leaves at the bottom of the exchanger, at 90 degrees, while the liquid leaves at the bottom.Rising/Falling Film Tubular EvaporatorThe tube side of the unit is two pass.Liquid enters at the bottom of the vertical vessel.Liquid is heated and may boil slightly passing up through the first pass.When it reaches the top of the exchanger, the liquid is equally distributed to the tubes and, just like the falling film evaporator, forms a film along the ID of the tubes and boils on the way down.

How Falling Film Evaporators Are Constructed How Falling Film Ev

Falling film evaporators are vertical shell and tube heat exchangers. Typical TEMA types are BEM, NEN or a combination of the two. The major difference between a typical shell and tube heat exchanger and a falling film evaporator is the liquid distribution at the top of the unit. Liquid entering the top of the unit passes either through a spray ball or through an internal distributor to ensure equal distribution of the liquid to all of the tubes.

How Falling Film Evaporators Work How Falling Film Evaporators W

In falling film evaporators, the liquid product usually enters the evaporator at the head of the evaporator. In the head, the product is evenly distributed into the heating tubes. The liquid enters the heating tube and forms a thin film on the tube wall where it flows downwards at boiling temperature and is partially evaporated. In most cases, steam is used for heating the evaporator. The product and the vapor both flow downwards in a parallel flow. This gravity-induced downward movement is increasingly augmented by the co-current vapor flow. The separation of the concentrated product from its vapor takes place in the lower part of the heat exchanger and the vapor/liquid separator.

Industries Industries

Agricultural Chemical Production | Chemical Production | Food and Beverage | Fuel Ethanol | Oil and Gas | Pharmaceutical Production | Pulp and Paper

Key Benefits Key Benefits

Short product contact time minimizes thermal degradation effectsLow tube wall temperature and heat flux minimizes foulingPerformance provides high efficiency for multiple effect designs.Suitable for heat sensitive products High vapor shear reduces foaming productsTurndown on recirculation designs is close to infinite