Thermal Kinetics IPFC Evaporator

Thermal Kinetics IPFC Evaporator

SKU:EVA-89083b

Efficient and versatile IPFC Evaporator for large-scale industrial crystallization processes. Maximize productivity and cost-effectiveness.

Regular price

$6,999.00

Regular price

Sale price

$6,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

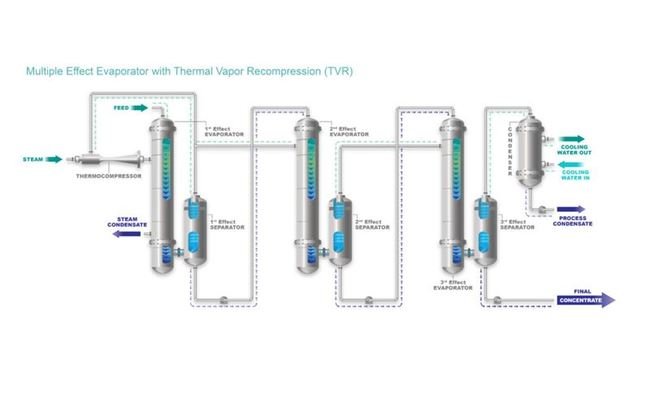

The Thermal Kinetics IPFC Evaporator is a high-performance solution designed for large-scale crystallization processes in industries such as Agricultural Chemical Production, Food and Beverage, and Pharmaceutical Production. With advanced features like internal pump forced circulation technology, vapor disengagement separators, and a range of application options, this evaporator ensures efficient and cost-effective operation for various industrial applications.

Product Specifications

Additional Information Additional Information

Thermal Kinetics offers a number of industrial crystallizer design options covering inorganic salts, precipitates, and a wide range of industrial chemicals. Thermal Kinetics provides three types of crystallization processes:by concentrationby cooling (under vacuum or with a heat exchanger)by reaction or equilibrium displacementWe possess the expertise for all types of crystallization equipment: with total or partial classification, involving the recirculation of the magma, with or without settling zones.

Applications Applications

Brewery Waste Concentration Systems | Cannabinoid Oil Refining | Chemical Plant Waste Systems | Chemical Recovery In Metal Plating processes | Concentration Of Sugar Solutions | Evaporative Crystallizers For Salts | Gelatin Production | Pharmaceutical Product Recovery From Waste Streams | Phosphoric Acid Production | Removal Of Solvents From Oils | Sodium Hydroxide (NaOH) Production | Sulfuric Acid Production

Components Components

Condenser | Heat Recovery Exchangers | Main Evaporator Heater | Vacuum System | Vapor/Liquid Separator

Construction Construction

This design is recommended for large volume crystallization and large capacity partial site fabricated evaporators requiring vapor disengagement separators exceeding 14 to 16 feet in diameter. The evaporator calandria (heated section) is mounted under the vapor liquid separator and an axial flow pump housing comprises the bottom head of the calandria. The internal circulating pump eliminates expensive external piping and pressure loses as well as associated valves.

Industries Industries

Agricultural Chemical Production | Chemical Production | Food and Beverage | Fuel Ethanol | Oil and Gas | Pharmaceutical Production | Pulp and Paper