USS Flat Washer - Plain, Carbon Steel, 2 1/4 in

USS Flat Washer - Plain, Carbon Steel, 2 1/4 in

SKU:TRA-7fec30

High-quality USS Flat Washer made of carbon steel with plain finish, ensuring durability and reliability in fastening applications.

Regular price

$45.99

Regular price

Sale price

$45.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The USS Flat Washer is a high-quality, heavy-duty washer designed for a wide range of applications. Made of durable carbon steel and featuring a plain finish, this washer ensures reliable performance and longevity. With a size of 2 1/4 inches and a weight of 82.60 lb per hundred pieces, it is suitable for various industrial and construction projects. Compliant with stringent industry standards, this USS Flat Washer guarantees precision and stability in fastening systems.

Product Specifications

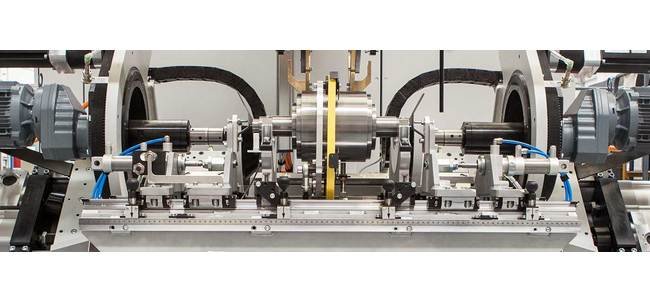

Higher Efficiency Higher Efficiency

Highest balancing qualityEasy and fast changeoverDual axial drilling for parallel correctionEasy loading and unloadingFast precise handling between stations

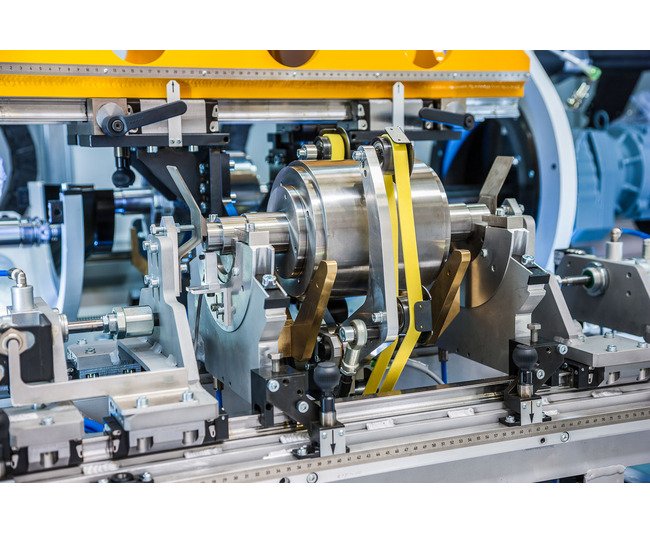

Highest Precision Highest Precision

Folding Belt Drive for precise measurement resultsAerostatic bearings in the measuring stationSmallest achievable measurement uncertainty (workpiece-dependent): 5 μinMeasuring Instrument CAB 950 for maximum precision and intuitive operation

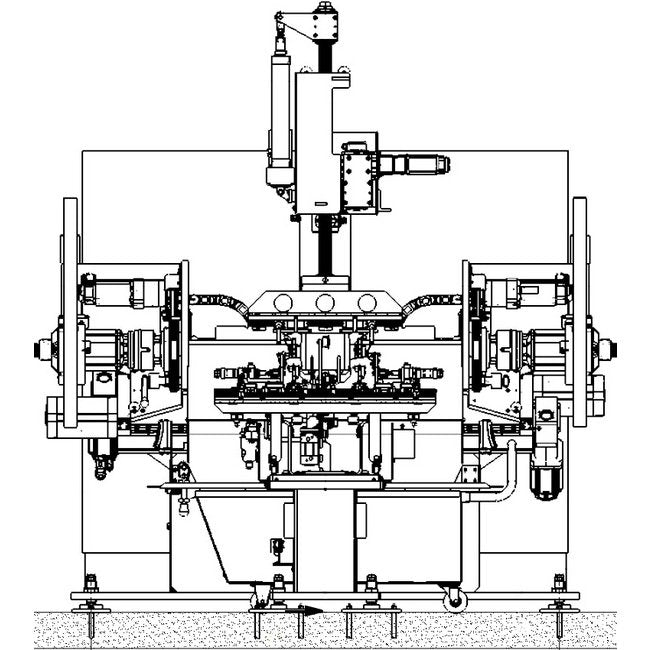

Machine Machine Depth

2800 mm

Machine Machine Height

3000 mm

Machine Machine Width

3300 mm

Machine Total Weight

5000 kg

Maximum Flexibility Maximum Flexibility

The flexible solution for the perfectly balanced rotor for eMobility or similar geometry rotorsFlexible Rotor LoadingConsistent implementation of the balancing process in mass production.

Power Supply Frequency

50 Hz

Power Supply Frequency Tolerance

2 %

Power Supply Note For Operating Voltage

As per International Electrotechnical Commission (IEC) 38

Power Supply Number Of Phase

3

Power Supply Operating Voltage

400 V

Power Supply Operating Voltage Tolerance

10 %

Rotor Journal Diameter

15 to 60 mm

Rotor Overall Length

150 to 500 mm

Rotor Rotor Diameter

60 to 200 mm

Rotor Rotor Type

Journals on both sides

Rotor Rotor Weight

2.5 to 50 kg

Scope Of Application Scope Of Application

The eTENO is the perfect solution for balancing eDrives or similar rotors up to 50 kg fully automatically and with high precision.Maximum flexibility:The eTENO offers maximum flexibility thanks to the two-station concept with a separate measuring and balancing station. The two-station concept enables significantly shorter cycle times and better measurement and correction results. This concept also allows flexible storage in the measuring station z. B. with prisms, idlers or aerostatic bearings for highest precision. In the balancing station a variety of correction options such as axial drilling, radial drilling, radial slot milling, axial / radial finger milling, additive correction are possible - all with the highest balancing quality.Easy installation and Change overThe high flexibility of the eTENO also comes into play when changing to another rotor. Good accessibility, simple and intelligent design of the controls, linear units with setting positions for quick and precise location retrieval support of the correction process and increase the efficiency of the production process.State of the Art Measuring and controlling:Our current measuring and control unit CAB950 in the SmartTouch version is designed as an intuitive and self-explanatory human-machine interface (MMS). It allows a comfortable and clear access to all functions of the machine.In addition to precise mechanics, CAB measurement technology guarantees the highest precision in balancing unbalance. Many off-the-shelf features optimize accuracy when balancing eDrives. The CAB950 is ready for linking into the digital world. It offers all options from the service app to production monitoring, our modern measuring and control technology.

Special Features Special Features

Modular machine conceptAll stations can be flexibly integrated into various assembly lines or operated in their own protective shroud, as a standalone unit.

Technical Data Brands

SCHENCK

Technical Data Cycle Time

40 to 100 seconds

Technical Data Direct Current Dc Control Voltage

24 V

Technical Data Input Power

34 kW

Technical Data Internal Device Alternating Current Ac Voltage

230 V

Technical Data Lubrication

Long-term of lifetime lubrication

Technical Data Maximum Back Up Fuse By Customer

25 A

Technical Data Maximum Noise Level

75 dBA

Technical Data Minimum Air Pressure

5.5 bar

Technical Data Technical Availability

99 % Nach VDI 3423