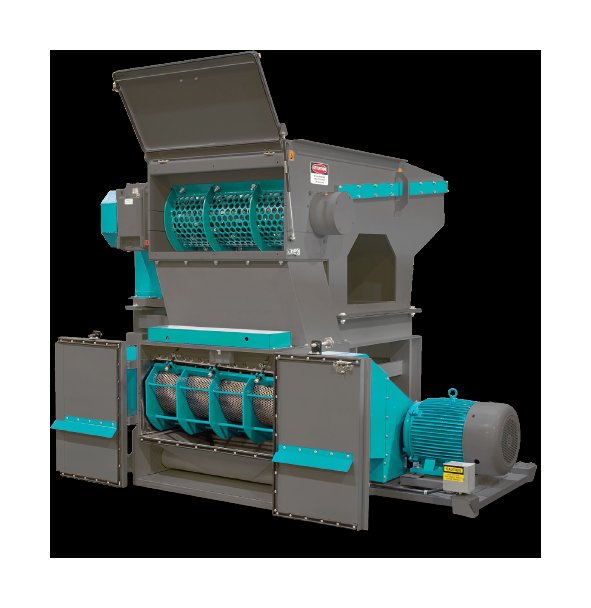

Vecoplan® VAZ-1100XL Stacked System

Vecoplan® VAZ-1100XL Stacked System

SKU:VEC-a2c7ba

Vecoplan® VAZ-1100XL Stacked System: Shred and granulate plastics with efficiency and precision. Ideal for waste management applications.

Regular price

$28,999.99

Regular price

Sale price

$28,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Vecoplan® VAZ-1100XL Stacked System integrates cutting-edge shredding and granulating technologies into a seamless solution, designed to process plastics efficiently. This system offers a balanced approach to plastic scrap reduction, combining a powerful shredder with a precise granulator. With features like low speed/high torque design, touch pad monitoring, and tramp metal protection, this system ensures optimal performance and longevity. Ideal for institutional and government buyers seeking reliable and efficient waste processing solutions.

Product Specifications

Efficiency In A Single System

The most time and cost efficient way to reduce large plastic scrap down to relatively small (larger than 3/8") size is with a cutting rotor turning at slow speeds but with high torque. A shredder does exactly that. To achieve a final particle size of 3/8" or less, a cutting rotor turning at high speeds but with low torque is more efficient. A granulator does exactly that. By combining both a shredder and a granulator, Vecoplan® Stacked Systems deliver the advantages inherent in both technologies.

Features

Low Speed / High Torque DesignTouch Pad Monitoring and ControlEasy AccessibilityTramp Metal ProtectionEquity "Buyback" GuaranteeRPM / Low NoiseLarge Infeed HopperPrecision Hydraulic "Process Ram"4-Way, Indexable Cutting InsertsHigh Output "Torsion Point" Cutting RotorHeavy-Duty ConstructionRugged HydraulicsStress-Free Frame, Robotically WeldedOversized DrivetrainHeavy Spherical Roller BearingsFluid "Turbo Coupling"PLC Control PanelISO 9001 Manufactured

Options

Magnetic Separation and ProtectionElectro-Magnetic DrivesSystem-Wide Interlock to Downstream Equipment

Specifications Cutting Chamber Sizes

32 to 70 | 40 to 80

Specifications Range

500 to 8,000 lb/hr

The Granulator

The second step in Vecoplan®'s Stacked System design is the granulator. Once material is reduced to a manageable size, it is then fed into the granulating second stage where it is processed to a controlled, final particle size. This allows efficient in-house recycling of scrap for re-use in the production run. Due to it's inherent design. The stacked system is a compact unit with a minimal footprint, making it perfect for operations with limited floor space.

The Shredder

The first step in Vecoplan®'s Stacked System design is the shredder. Fifty years of expertise in size reduction technology is built into every shredder from Vecoplan®. Vecoplan®'s single shaft shredders are the most widely used in the world, and offer controllable and changeable shredded particle output size via interchangeable screens. Vecoplan® screens are inexpensive and can be quickly and easily changed, allowing you to control and change particle size to fit your specific application – now and in the future. All Vecoplan® shredder features are engineered specifically to provide the most effective operation, with more cost efficiency and to make maintenance easier and less expensive. The heavy-duty, quality construction means that Vecoplan® shredders require less maintenance and last longer than other machines.