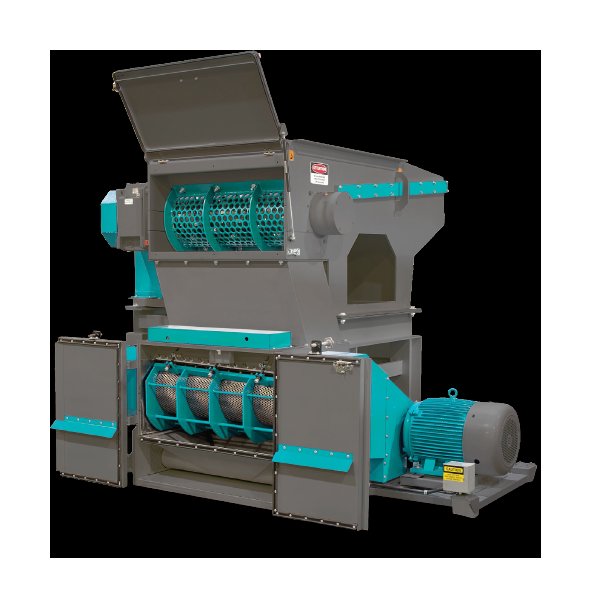

Vecoplan® VAZ-1600 NewGen Stacked System

Vecoplan® VAZ-1600 NewGen Stacked System

SKU:VEC-8f6861

Vecoplan® VAZ-1600 NewGen: The ultimate plastic recycling solution for high-capacity processing. Efficiency meets innovation in this compact system.

Regular price

$49,999.99

Regular price

Sale price

$49,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Vecoplan® VAZ-1600 NewGen is a cutting-edge solution for plastic recycling, seamlessly integrating a shredder and granulator to efficiently process plastic scrap. With a processing range of 500 to 8,000 lb/hr, this system offers unmatched productivity and quality. Equipped with innovative features like Touch Pad Monitoring, Tramp Metal Protection, and Precision Hydraulic Process Ram, the Vecoplan® VAZ-1600 ensures optimal performance and durability. Its low-speed, high-torque design and compact footprint make it ideal for facilities with limited space. Enhance your plastic recycling capabilities with the Vecoplan® VAZ-1600 NewGen Stacked System.

Product Specifications

Efficiency In A Single System

The most time and cost efficient way to reduce large plastic scrap down to relatively small (larger than 3/8") size is with a cutting rotor turning at slow speeds but with high torque. A shredder does exactly that. To achieve a final particle size of 3/8" or less, a cutting rotor turning at high speeds but with low torque is more efficient. A granulator does exactly that. By combining both a shredder and a granulator, Vecoplan® Stacked Systems deliver the advantages inherent in both technologies.

Features

Low Speed / High Torque DesignTouch Pad Monitoring and ControlEasy AccessibilityTramp Metal ProtectionEquity "Buyback" GuaranteeRPM / Low NoiseLarge Infeed HopperPrecision Hydraulic "Process Ram"4-Way, Indexable Cutting InsertsHigh Output "Torsion Point" Cutting RotorHeavy-Duty ConstructionRugged HydraulicsStress-Free Frame, Robotically WeldedOversized DrivetrainHeavy Spherical Roller BearingsFluid "Turbo Coupling"PLC Control PanelISO 9001 Manufactured

Options

Magnetic Separation and ProtectionElectro-Magnetic DrivesSystem-Wide Interlock to Downstream Equipment

Specifications Cutting Chamber Sizes

32 to 70 | 40 to 80

Specifications Range

500 to 8,000 lb/hr

The Granulator

The second step in Vecoplan®'s Stacked System design is the granulator. Once material is reduced to a manageable size, it is then fed into the granulating second stage where it is processed to a controlled, final particle size. This allows efficient in-house recycling of scrap for re-use in the production run. Due to it's inherent design. The stacked system is a compact unit with a minimal footprint, making it perfect for operations with limited floor space.

The Shredder

The first step in Vecoplan®'s Stacked System design is the shredder. Fifty years of expertise in size reduction technology is built into every shredder from Vecoplan®. Vecoplan®'s single shaft shredders are the most widely used in the world, and offer controllable and changeable shredded particle output size via interchangeable screens. Vecoplan® screens are inexpensive and can be quickly and easily changed, allowing you to control and change particle size to fit your specific application – now and in the future. All Vecoplan® shredder features are engineered specifically to provide the most effective operation, with more cost efficiency and to make maintenance easier and less expensive. The heavy-duty, quality construction means that Vecoplan® shredders require less maintenance and last longer than other machines.